A double-action double-tube single-bit core drilling tool and its application method

A core drilling tool and single-bit technology, applied in the direction of extracting undisturbed core devices, drill pipes, casings, etc., can solve the problem of large water passing area, achieve large water passing area, remove rock powder quickly, and reduce drilling tools The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

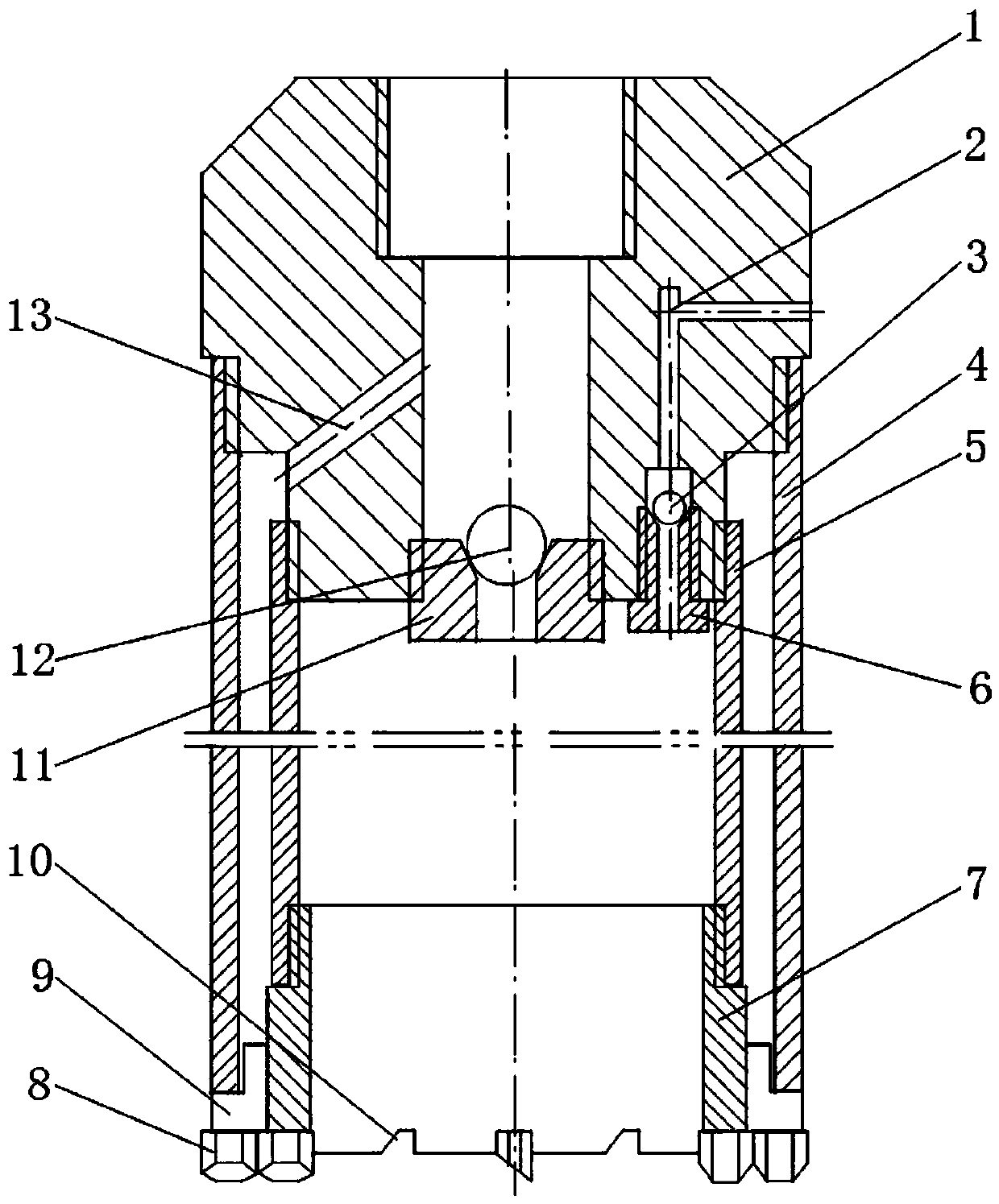

[0038] Combine figure 1 As shown, the dual-action dual-tube single-bit core drilling tool of this embodiment includes an inner and outer core pipe joint 1, an outer pipe 4, and an inner pipe 5. The outer pipe 4 and the inner pipe 5 are respectively fixed to the inner and outer core pipe joint 1 The outer tube 4 is sleeved on the outer side of the inner tube 5, and an annular gap is left between the outer tube 4 and the inner tube 5. The outer tube 4 and the inner tube 5 can be threaded to the inner and outer core pipe joint 1. The pipe joint 1 is connected to the drill pipe joint through the threads on it; in this embodiment, the outer diameter of the outer pipe 4 is The inner tube 5 matches the outer tube 4, and the overall length of the drilling tool is 1.5-2m. The inner and outer core pipe joint 1 is provided with a liquid injection hole and a water diversion hole 13 connecting the above-mentioned annular gap and the liquid injection hole. The water diversion hole 13 is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com