Submersible type mixing system based on water turbine

A mixing system and water turbine technology, applied in mechanical equipment, hydropower, non-variable pumps, etc., can solve the problems of unfavorable impact on water treatment process continuity, shortening the service life of motors, damage to sealing systems, etc., and achieve good adaptability to sewage Effects of working conditions, reduced maintenance costs, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

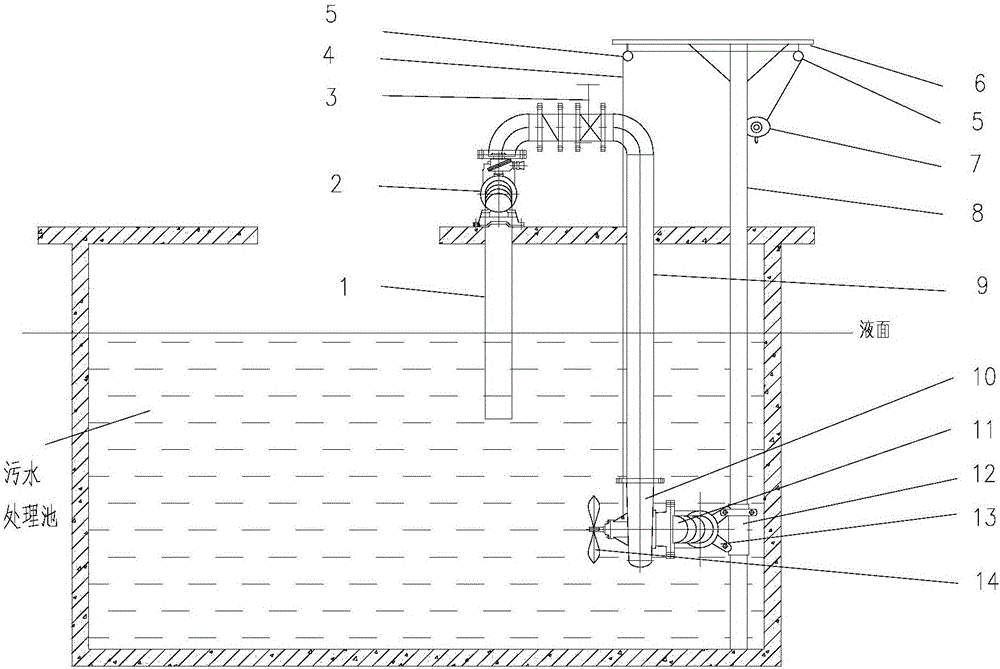

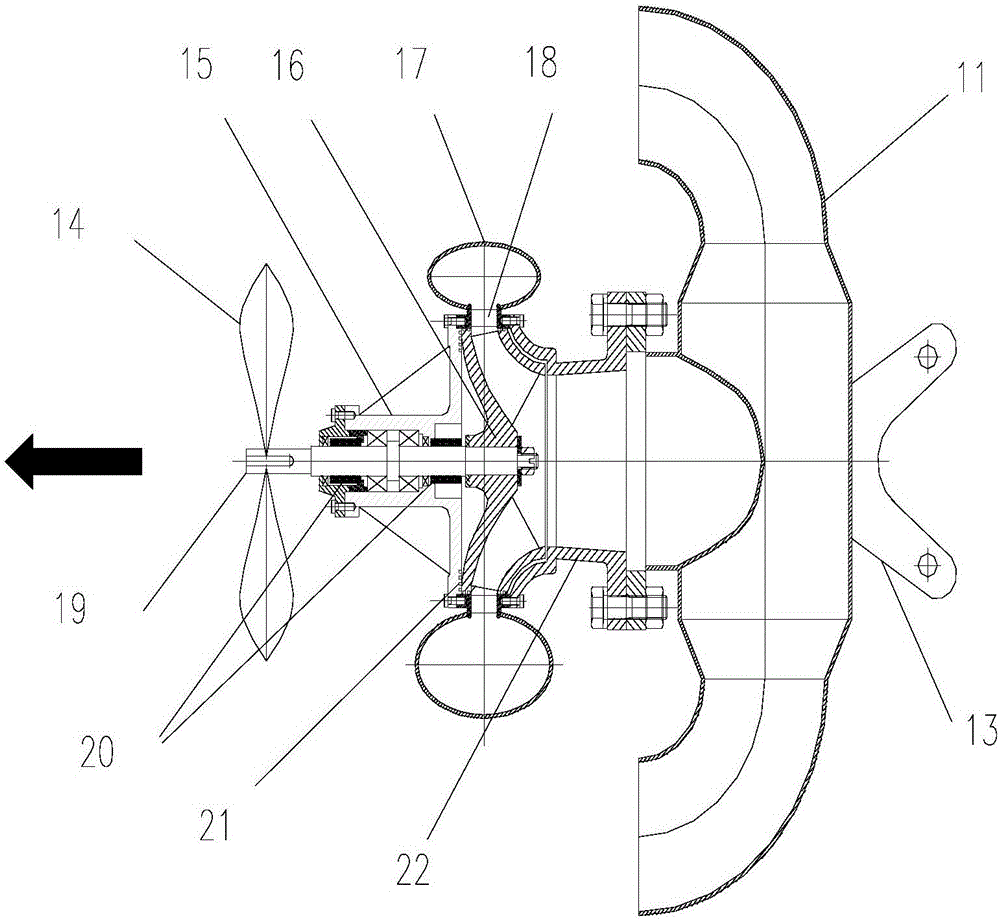

[0019] The structure of the device of the present invention is as figure 1 As shown, it consists of a water suction pipe 1, a water pump 2, a regulating valve 3, a steel wire rope 4, a pulley 5, a lifting bracket 6, a rocker 7, a base rail frame 8, a water outlet hose 9, a micro-turbine 10, and a tail water pushing pipe 11 , Damping slide block 12, angle adjustment block 13, stirring impeller 14 etc. constitute.

[0020] During field work, turn rocking handle 7, drive wire rope 4 and pulley 5, descend micro-turbine 10 and stirring impeller 14 to set depth, adjust the orientation of stirring impeller 14 by angle adjustment block 13, fix rocking handle 7 then. Start the water pump 2, turn the regulating valve 3, adjust the flow to the rated working flow of the micro-turbine 10, and the micro-turbine 10 drives the stirring impeller 14 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com