Thermostatically controlled hydraulic hose pulse test platform

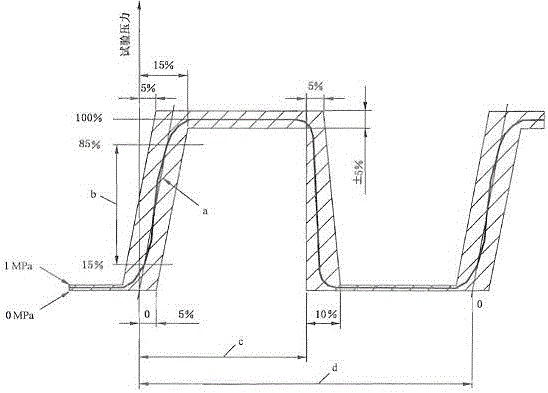

A technology of hydraulic hose and pulse test, which is used in the testing of fluid pressure actuation systems, fluid pressure actuation devices, mechanical equipment, etc. It is convenient to control the pulse waveform, improve the service life, and stabilize the oil temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

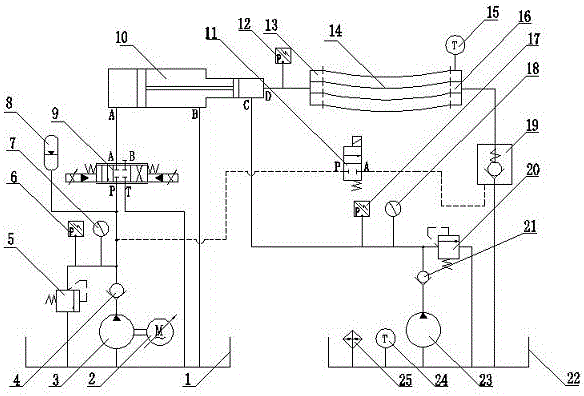

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

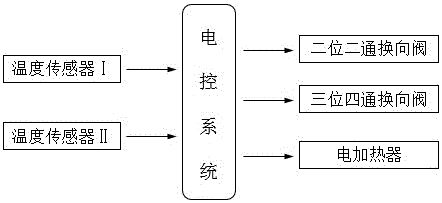

[0019] As shown in the drawings, the hydraulic hose pulse test bench of the present invention includes an electric control system, a pulse loading system, an oil replenishment system, a tested hydraulic hose connection valve block I13 and a tested hydraulic hose connection valve block II16.

[0020] The pulse loading system includes main oil tank 1, hydraulic pump I3, one-way valve I4, overflow valve I5, accumulator 8, three-position four-way solenoid valve 9, booster cylinder 10; The oil port is connected with the oil outlet of the overflow valve I5; the hydraulic pump I3 is driven by the frequency conversion motor 2, and the oil outlet of the hydraulic pump I3 is connected with the oil inlet of the one-way valve I4; the oil outlet of the one-way valve I4 There is a pressure sensor I6 and a pressure gauge I7, and the oil outlet of the one-way valve I4 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com