A secondary treatment method for sodium flue gas desulfurization liquid

A secondary treatment and desulfurization liquid technology, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of destruction, ecological environment and drinking water quality pollution, etc., to achieve simple and convenient operation, maintenance stability, process Reasonable effect of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

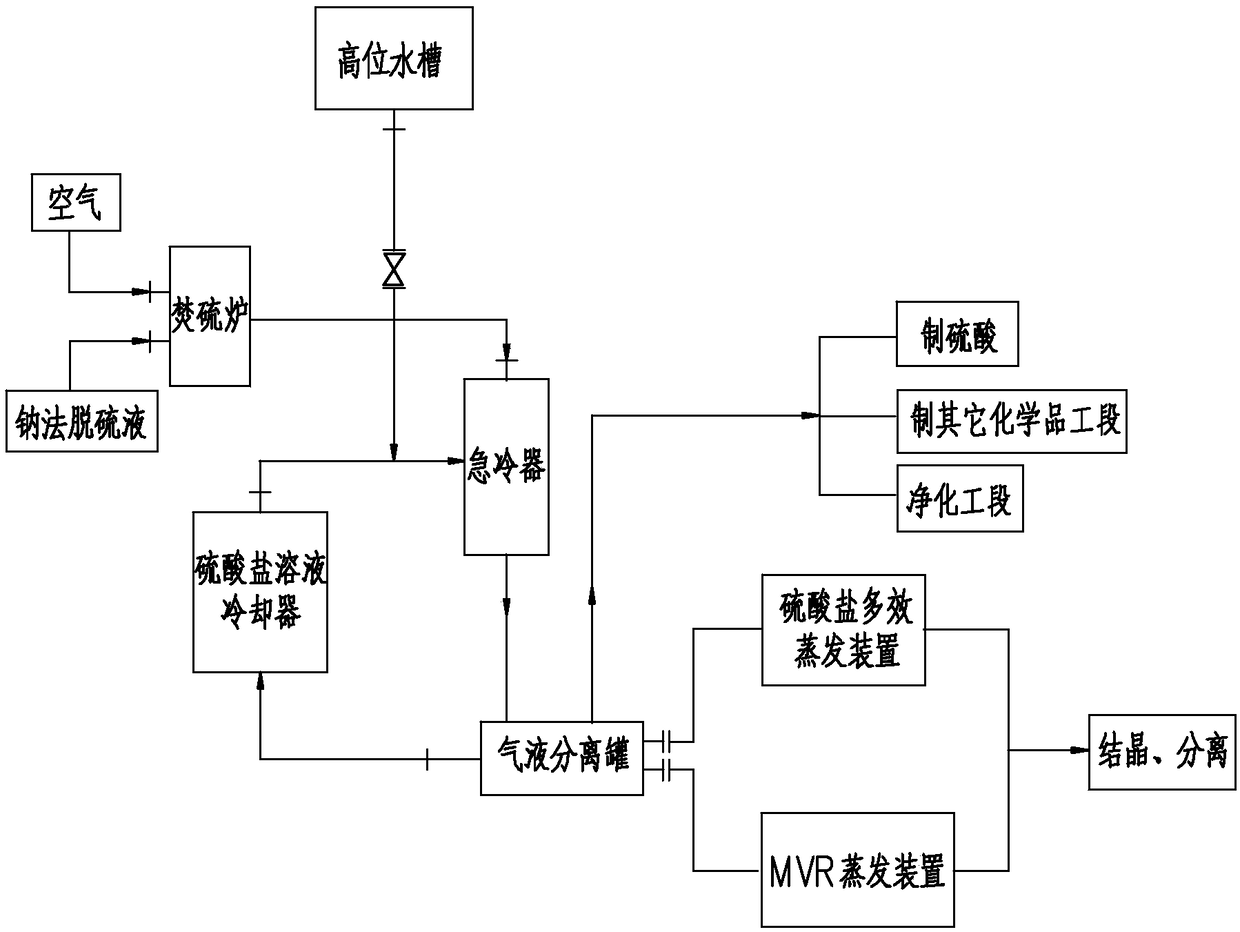

[0018] Such as figure 1 Shown, the concrete step flow process of the present invention is as follows:

[0019] a. Send the sodium desulfurization solution and air into the sulfur incinerator for high-temperature incineration, so that the sulfuric acid in the sodium desulfurization solution is rapidly cracked at a high temperature of 1000-1200 ° C to generate SO 2 、H 2 O, N 2 , O 2 , CO 2 , SO 3 And high-temperature furnace gas with a small amount of molten or solid sulfate;

[0020] b. The high-temperature furnace gas is transported to the quencher through pipelines at a high flow rate, and the temperature of the high-temperature furnace gas is instantly reduced to below 70°C by using the structural characteristics of the quencher; the quencher is made of high-strength graphite, and the liquid inlet pipe of the quencher A high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com