Fully-distributed tooth root bending stress dynamic detecting device and method

A technology of bending stress and dynamic detection, which is applied in the measurement device, the measurement of the change force of the optical properties of the material when it is stressed, and the measurement of the force, can solve the complex process, cannot be measured by points, and cannot realize real-time dynamic measurement. Measurement and other issues, to achieve high spatial resolution, high accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

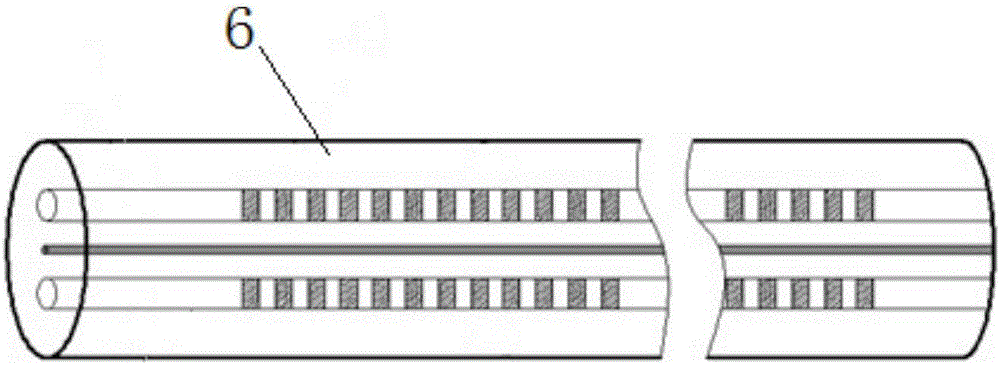

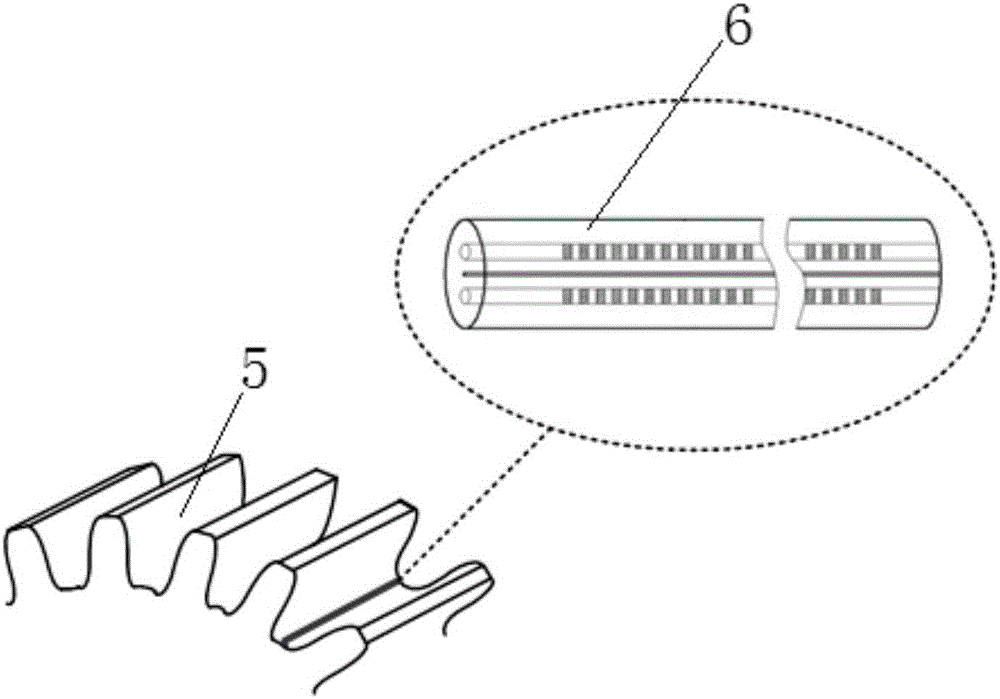

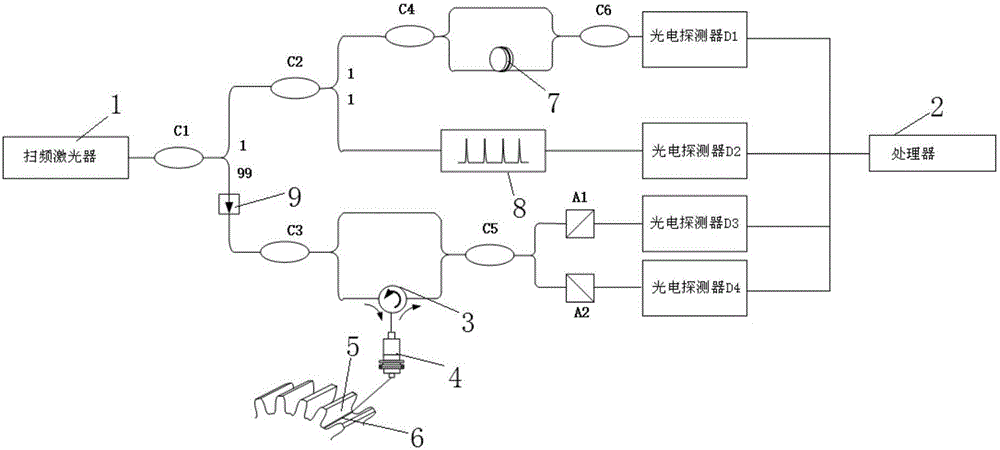

[0032] A fully distributed root bending stress dynamic detection device of the present invention, such as Figure 1~3 As shown, it includes frequency-sweeping laser 1, optical splitter C1, optical splitter C2, coupler C3, coupler C4, polarization-maintaining optical coupler C5, coupler C6, analyzer A1, analyzer A2, Photodetector D1, photodetector D2, photodetector D3, photodetector D4, optical circulator 3, optical fiber rotary connector 4, time-delay optical fiber 7, wavelength calibrator 8, isolator 9, processor 2, along The gear dedendum 5 is axially attached to the polarization maintaining fiber grating 6 on the gear dedendum 5, wherein the frequency sweep signal output end of the frequency sweep laser 1 is connected to the input end of the optical splitter C1, and the output end of the optical splitter C1 The first output end is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com