Device and method for evaluating saturation capacity of moveable oil in shale

An evaluation method, shale technology, applied in the direction of measuring devices, test sample preparation, sampling, etc., can solve the problem of not being able to represent the developable oil reserves of movable oil, affecting oil and water saturation, and being unable to determine oil and water, etc. problem, to achieve the effect of shortening the experimental cycle, speeding up self-priming, and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

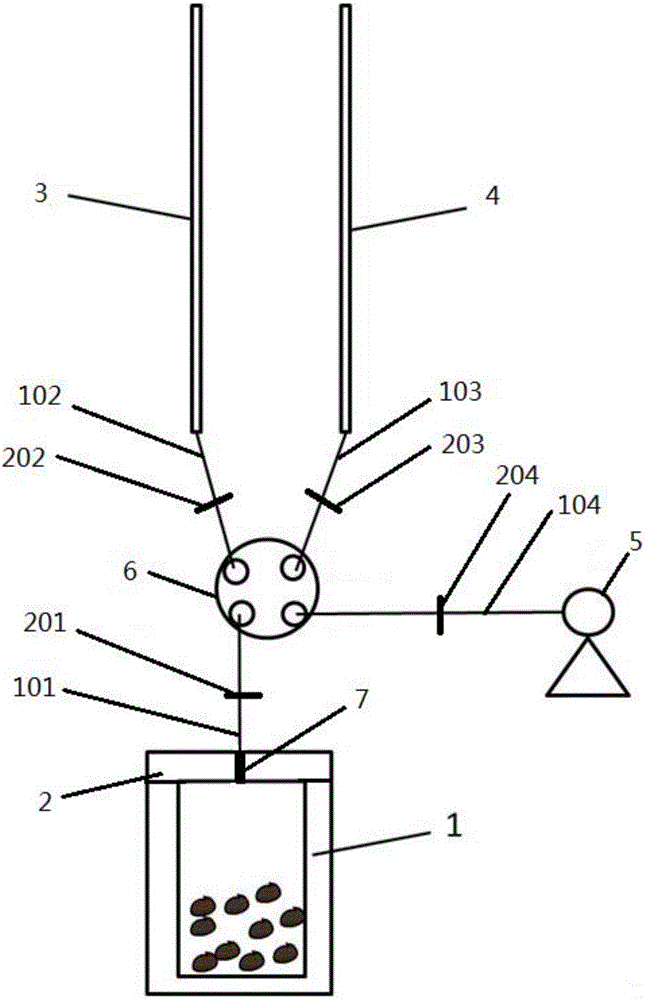

Method used

Image

Examples

Embodiment 1

[0094] Select the crushed sample 1 after oil washing and drying, weigh a sample with a mass of 46.76g, and add it to the airtight sample tank 1. The density of the sample is 2.21g / cm 3 , V 样 21.16cm 3 , through experiments, the initial and final volumes of the liquid in the first scale tube are 100.00 and 65.26 cm respectively 3 , the initial and final volumes of the liquid in the second graduated tube are 100.00 and 64.18 cm, respectively 3 , therefore, it can be calculated that the saturated amount ω′ of the alkane existing in the free state and the saturated amount ω″ of the alkane existing in the adsorbed dissolved state in the sample 1 are respectively 0.041 cm 3 / g and 0.023cm 3 / g.

Embodiment 2

[0096] Select the broken sample 2 that has been washed and dried, weigh a sample with a mass of 63.5g, and add it to a closed sample tank. The density of the sample is 2.42g / cm 3 , V 样 26.2cm 3 , through experiments, the initial and final volumes of the liquid in the first scale tube are 100.00 and 70.22 cm respectively 3 , the initial and final volumes of the liquid in the second graduated tube are 100.00 and 69.43 cm, respectively 3 , therefore, it can be calculated that the saturated amount ω′ of the alkane existing in the free state and the saturated amount ω″ of the alkane existing in the adsorbed dissolved state in the sample two are 0.031 cm 3 / g and 0.012cm 3 / g.

Embodiment 3

[0098] Select the broken sample three that has been washed and dried, weigh a sample with a mass of 45.2g, and add it to a closed sample tank. The density of the sample is 2.34g / cm 3 , V 样 19.32cm 3 , the initial and final volumes of the liquid in the first scale tube are obtained through experiments to be 10.00 and 63.86 cm respectively 3 , the initial and final volumes of the liquid in the second graduated tube are 100.00 and 63.08 cm, respectively 3 , therefore, it can be calculated that the saturation amount ω′ of the alkane existing in the free state and the saturation amount ω″ of the alkane existing in the adsorbed dissolved state in the sample three are respectively 0.032cm 3 / g and 0.017cm 3 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com