Full-automatic oxygen-deficient corrosion testing device and testing method

A corrosion test, fully automatic technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of difficult to test the synchronous and precise control of the concentration of the solution agent and dissolved oxygen, and achieve stability and achieve Precisely controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

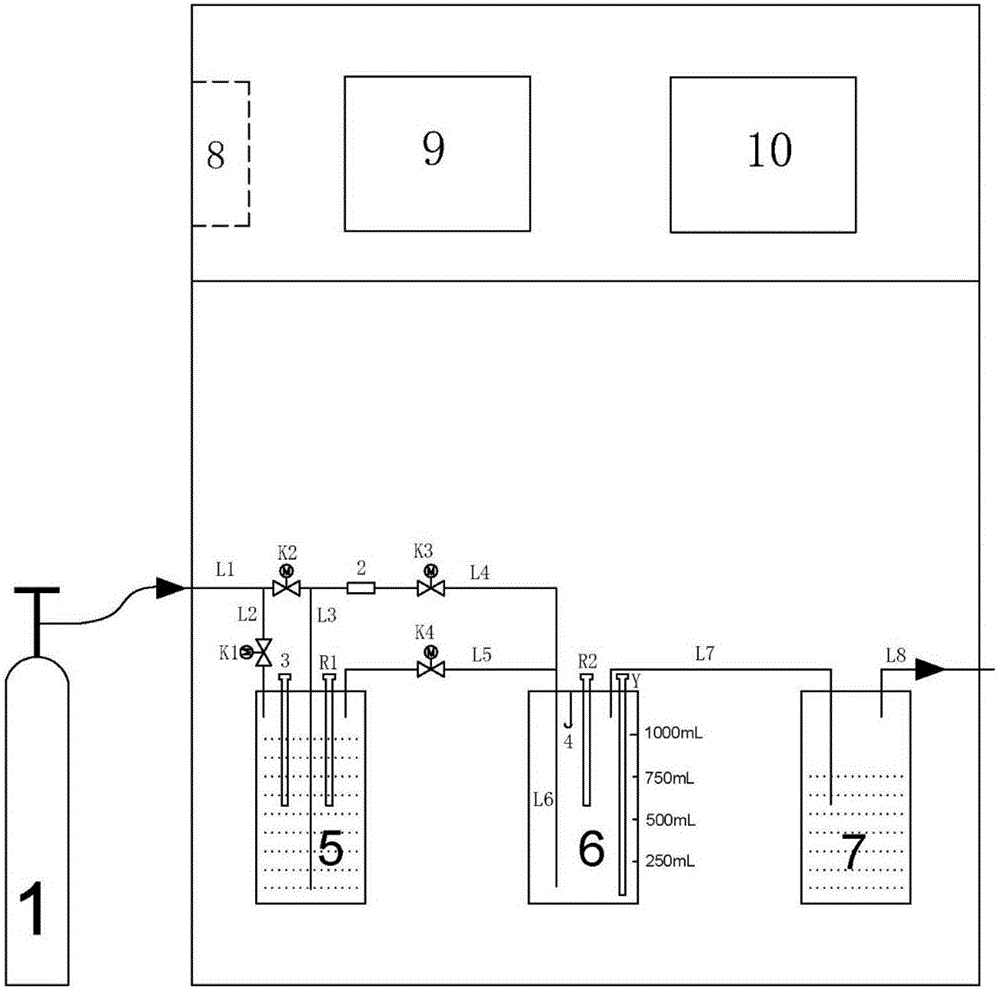

[0023] Such as figure 1 As mentioned above, the fully automatic oxygen-poor corrosion test device of this embodiment mainly consists of an inert gas bottle 1, a dosing device 2, an oxygen electrode 3, a sample hanger 4, a preparation device 5, a reactor 6, a sealed respirator 7, It is composed of pipeline (L1‐L8), electric valve (K1‐K4), thermocouple (R1, R2), liquid level sensor Y and PLC8 control system, etc.

[0024] All containers are square, and the containers, pipelines and electric valves are all made of PVC materials.

[0025] For the test method of the corrosion test device in this embodiment, the dissolved oxygen concentration is set to 0ppb by the man-machine interface, the test temperature is 40°C, the test time is 4h, the solution volume is 600mL, the test device is placed in a 40°C constant temperature water bath, and the sample hanger 4 Hang the carbon steel corrosion test piece, add 1000mL desalted water to the preparation device 5. The first step is the prep...

Embodiment 2

[0027] Such as figure 1 As described, a fully automatic oxygen-poor corrosion test device and method of the present invention mainly consists of a nitrogen bottle 1, a dosing device 2, an oxygen electrode 3, a sample hanger 4, a preparation device 5, a reactor 6, and a sealed respirator 7. It is composed of pipeline (L1‐L8), electric valve (K1‐K4), thermocouple (R1, R2), liquid level sensor Y and PLC8 control system, etc.

[0028] All containers are columnar and made of plexiglass, and the pipelines and electric valves are made of PVC.

[0029]For the test method of the corrosion test device in this embodiment, the dissolved oxygen concentration is set to 700ppb by the man-machine interface, the test temperature is 45°C, the test time is 4h, the solution volume is 700mL, the test device is placed in a 45°C constant temperature water bath, and the sample hanger (4) Hang the carbon steel corrosion test piece, add 1000mL desalted water into the preparation device (5). The first...

Embodiment 3

[0031] Such as figure 1 As described, a fully automatic oxygen-poor corrosion test device and method of the present invention mainly consists of a nitrogen bottle 1, a dosing device 2, an oxygen electrode 3, a sample hanger 4, a preparation device 5, a reactor 6, and a sealed respirator 7. It is composed of pipeline (L1‐L8), electric valve (K1‐K4), thermocouple (R1, R2), liquid level sensor Y and PLC8 control system, etc.

[0032] All containers are spherical, made of glass, the pipeline is made of polytetrafluoroethylene, and the electric valve is made of 304 stainless steel.

[0033] For the test method of the corrosion test device in this embodiment, the dissolved oxygen concentration is set at 6000ppb by the man-machine interface, the test temperature is 50°C, the test time is 5h, the solution volume is 500mL, the test device is placed in a 50°C constant temperature water bath, and the sample hanger 4 Hang the carbon steel corrosion test piece, add 1000mL desalted water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com