Temperature loading device for neutron scattering experiment

A neutron scattering and loading device technology, which is applied in material analysis using radiation diffraction, material analysis using wave/particle radiation, measuring devices, etc., can solve problems such as not having automatic sample change function, and achieve safe and reliable performance The effect of shortening operation time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

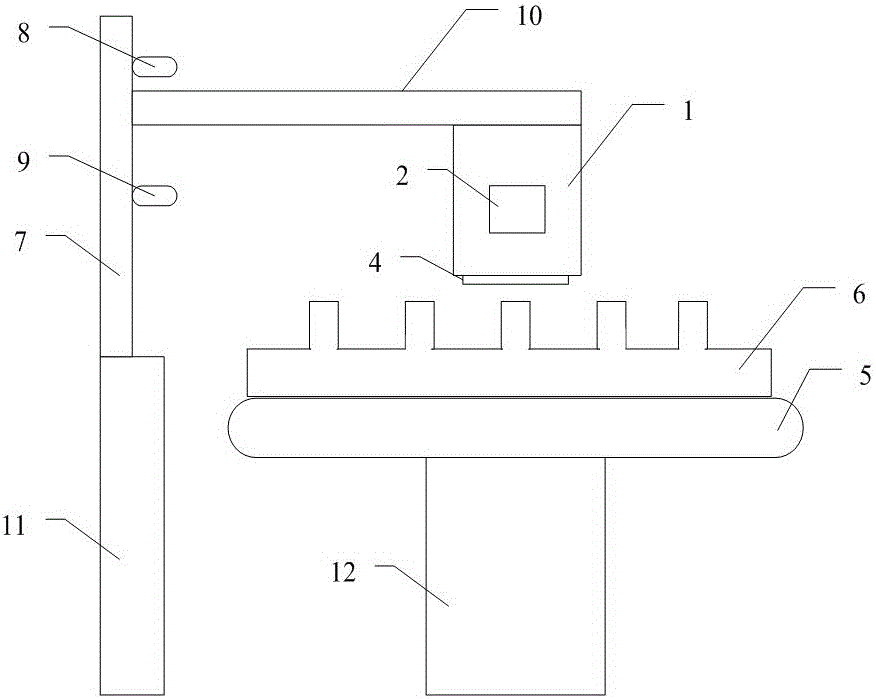

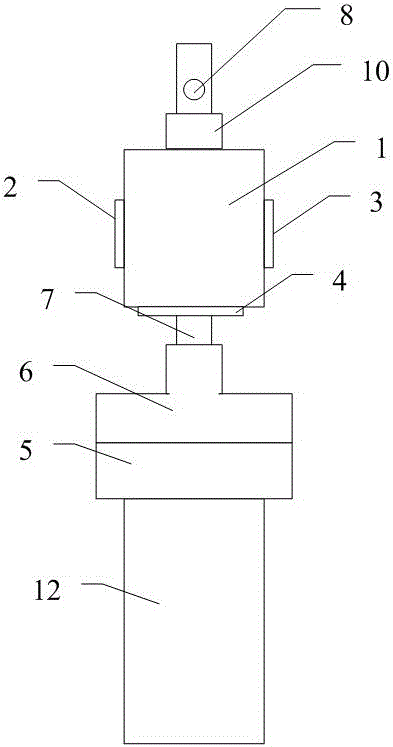

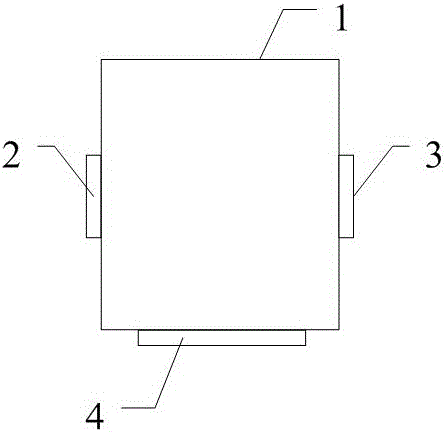

[0028] Such as Figure 1-4 As shown, the temperature loading device for neutron scattering experiments of the present invention includes a heating furnace, a translational sample stage, and a pneumatic lifting support; the heating furnace includes a furnace cavity 1, an incident window plate 2, an exit window plate 3, a water-cooled Tube 4, the translational sample stage includes a servo electric cylinder 5, a sample table top 6, and a sample stage base 12, and the pneumatic lifting support includes a lifting cylinder 7, a high position limit switch 8, a low position limit switch 9, a movable Support 10, lifting base 11; The described furnace body cavity 1 is provided with neutron entrance hole, neutron exit hole, and the bottom is provided with sample loading hole; Its connection relation is that incident window plate 2, exit window plate 3 are fixed on successively Outside the neutron injection hole and neutron exit hole of the furnace cavity 1, the water cooling tube 4 is i...

Embodiment 2

[0037]The structure of this embodiment is the same as that of Embodiment 1, except that the materials of the incident window plate 2 and the exit window plate 3 are made of sapphire, and the water-cooled pipe 4 is made of copper material, and the two ends are connected by circulating water pipes On the constant temperature water pump with refrigeration function, eight sample fixing brackets are arranged on the sample table 6, and the stroke range of the servo electric cylinder 5 is 720mm.

[0038] After the above implementation, the present invention can carry out the neutron measurement experiment under the in-situ temperature environment of neutron diffraction on the cold neutron diffraction spectrometer, the maximum loading temperature is 1000 degrees, and the automatic measurement of eight sample stages can be performed at one time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com