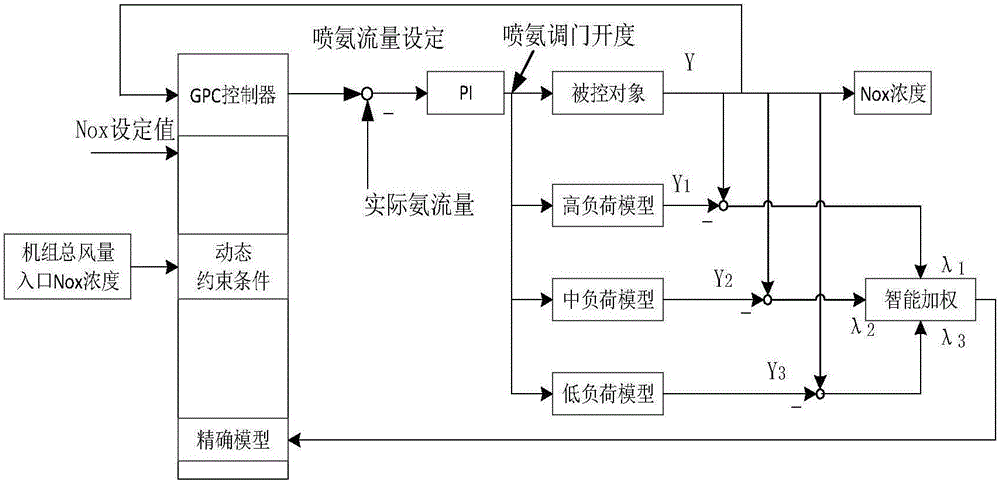

SCR denitrification control method based on variable-constraint multi-model prediction control

A technology of predictive control algorithm and control method, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems of drastic changes in SCR characteristics, high model accuracy requirements, limited model accuracy, etc., and achieve improved regulation Quality, overcoming large hysteresis characteristics, and improving the effect of model accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] A 1000MW supercritical unit in a power plant adopts the control method of the present invention, and based on this application scenario, the relevant parameters of the above formula are selected as:

[0062] At three load points of 1000MW, 750MW and 500MW, the step characteristic test of the opening of the ammonia injection door to the NOx concentration at the chimney inlet was carried out, and the relevant mathematical model was obtained through model fitting.

[0063]

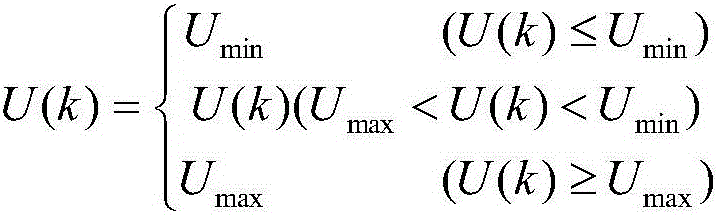

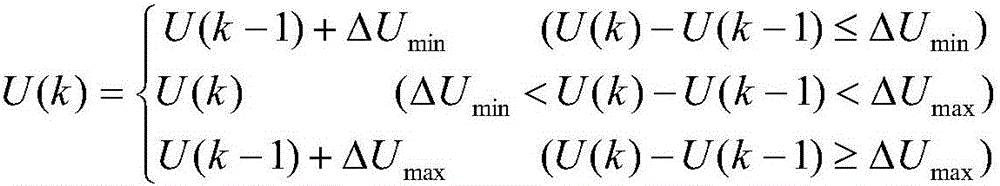

[0064] With 5s as the sampling period, discretize the above model; select the maximum number of prediction steps N=40, and the weight of the control quantity Γ=(0.6 ... 0.6) T ; Among the constraint conditions, the calculation coefficients of the upper and lower limits of the ammonia injection flow rate are A=0.001, B=15t / h, and the upper and lower limits of the ammonia injection flow rate change rate are ΔU min =-5t / h,ΔU max =5t / h; PI controller parameter of ammonia injection flow loop, ratio K p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com