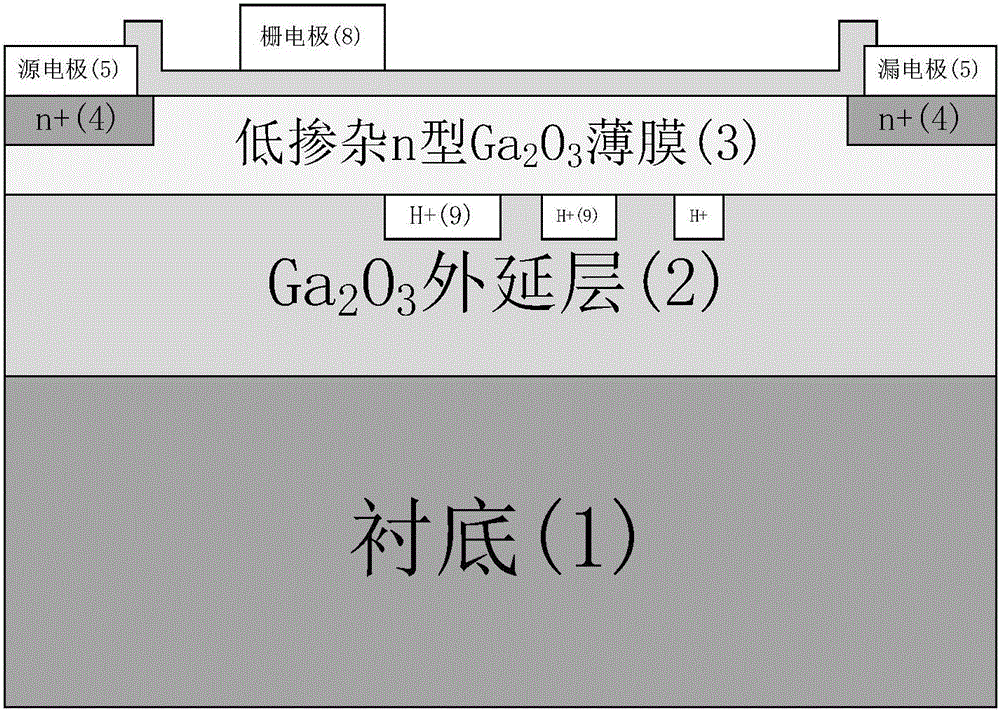

Metallic oxide semiconductor field effect transistor and manufacturing method thereof

A field-effect transistor, oxide semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as limiting breakdown field strength, gate-to-drain breakdown, and uneven electric field distribution of devices , to achieve the effect of weakening aggregation and increasing reverse breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

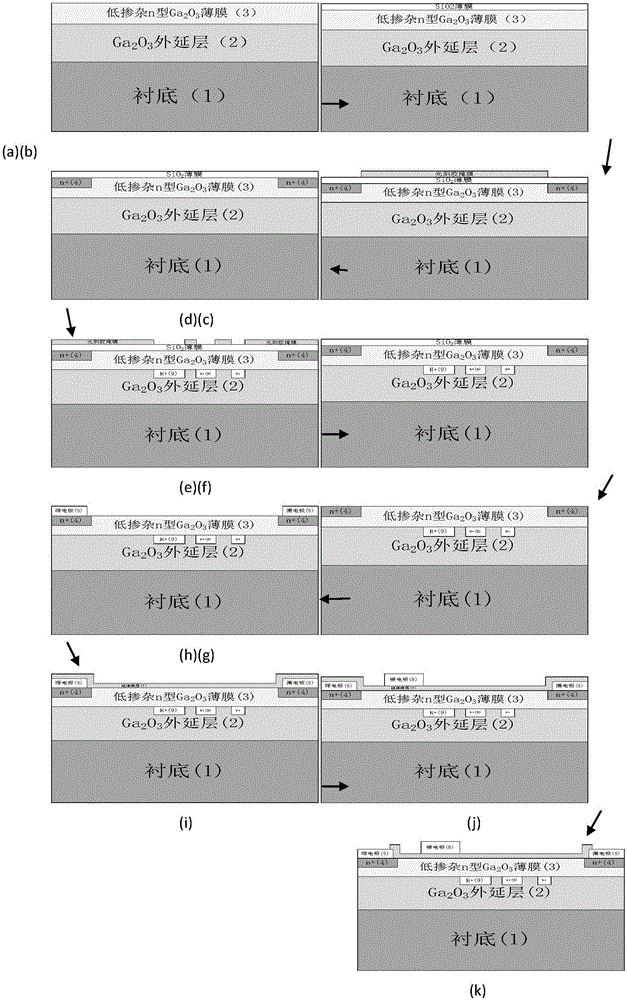

[0039] Example 1, making the substrate as Ga 2 o 3 , Si ions are implanted, and the insulating gate dielectric is Al 2 o 3 Metal Oxide Semiconductor Field Effect Transistors.

[0040] Step 1: Wash the sample as figure 2 (a) shown.

[0041] 1a) First, the epitaxially grown Ga on the substrate 2 o 3 The samples were cleaned organically, washed with flowing deionized water, and put into HF:H 2 Corrosion in the solution of O=1:1 for 60s;

[0042] 1b) The corroded sample was washed with flowing deionized water, and dried with high-purity nitrogen.

[0043] Step 2: Deposit SiO 2 mask, such as figure 2 (b) shown.

[0044] Put the cleaned sample into the PECVD equipment, set the reaction chamber pressure to 2Pa, the RF power to 40W, and simultaneously feed SiH with a flow rate of 40sccm 4 and a flow rate of 10 sccm N 2 O, in n-type Ga 2 o 3 SiO with a thickness of 50 nm was deposited on the film 2 mask.

[0045] Step 3: Make the ion implantation area, such as figu...

example 2

[0067] Example 2, the production substrate is sapphire, implanted with Sn ions, and the insulating gate dielectric is HfO 2 Metal Oxide Semiconductor Field Effect Transistors.

[0068] Step 1: Wash the sample, such as figure 2 (a) shown.

[0069] This step is the same as Step 1 of Example 1.

[0070] Step 2: Deposit SiO 2 mask, such as figure 2 (b) shown.

[0071] This step is the same as Step 2 of Example 1.

[0072] Step 3: Make the ion implantation area, such as figure 2 (c) shown.

[0073] 3.1) To complete SiO 2 The sample deposited by the mask is subjected to photolithography to form an ion implantation area;

[0074] 3.2) Put the photolithographic sample into the ion implantation reaction chamber to perform Sn ion implantation twice, the first implantation energy is 60keV, and the implantation dose is 3.2×10 14 cm -3 ; The second implantation energy is 30keV, and the implantation dose is 9.3×10 13 cm -3 ;

[0075] Step 4: Degelling and annealing activati...

example 3

[0091] Example 3, making the substrate as MgAl 2 o 4 , Ge ions are implanted, and the insulating gate dielectric is Si 3 N 4 Metal Oxide Semiconductor Field Effect Transistors.

[0092] Step A: Wash the sample as figure 2 (a) shown.

[0093] This step is the same as Step 1 of Example 1.

[0094] Step B: Deposit SiO 2 mask, such as figure 2 (b) shown.

[0095] This step is the same as Step 2 of Example 1.

[0096] Step C: Make the ion implantation area: that is, complete the SiO 2 Mask-deposited samples were subjected to photolithography to form ion implantation regions; then the photolithographic samples were placed in the ion implantation reaction chamber for two Ge ion implantations, the first implantation energy was 60keV, and the implantation dose was 3.2×10 14 cm -3 ; The second implantation energy is 30keV, and the implantation dose is 9.3×10 13 cm -3 ;like figure 2 (c) shown.

[0097] Step D: Degelling annealing activation, such as figure 2 (d) shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com