Multi-layer three-dimensional automatic moving seedbed system

A technology for moving seedbeds and single seedbeds, applied in the field of greenhouse seedbed space logistics system, can solve the problems of limited push stroke, low degree of intelligent control, damage to seedbeds and nurseries, etc., achieving stable and reliable functions, high degree of intelligence, and prevention of The effect of the seedbed falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

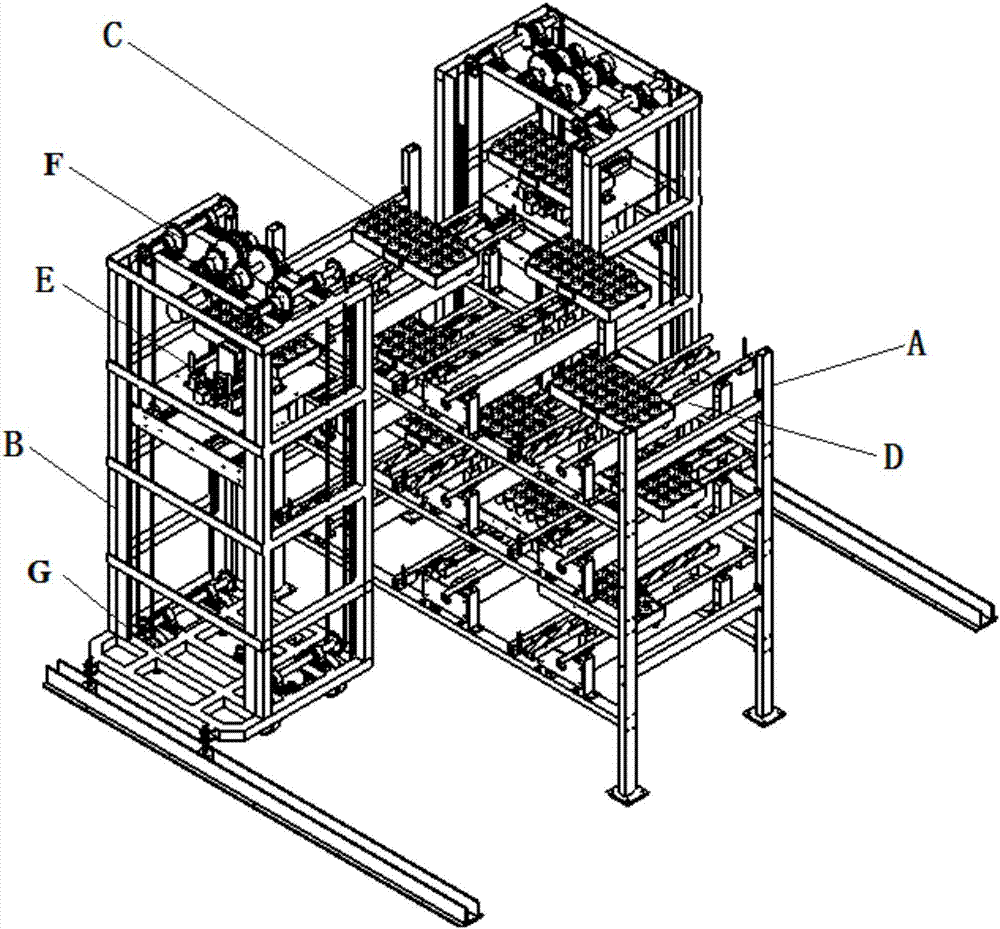

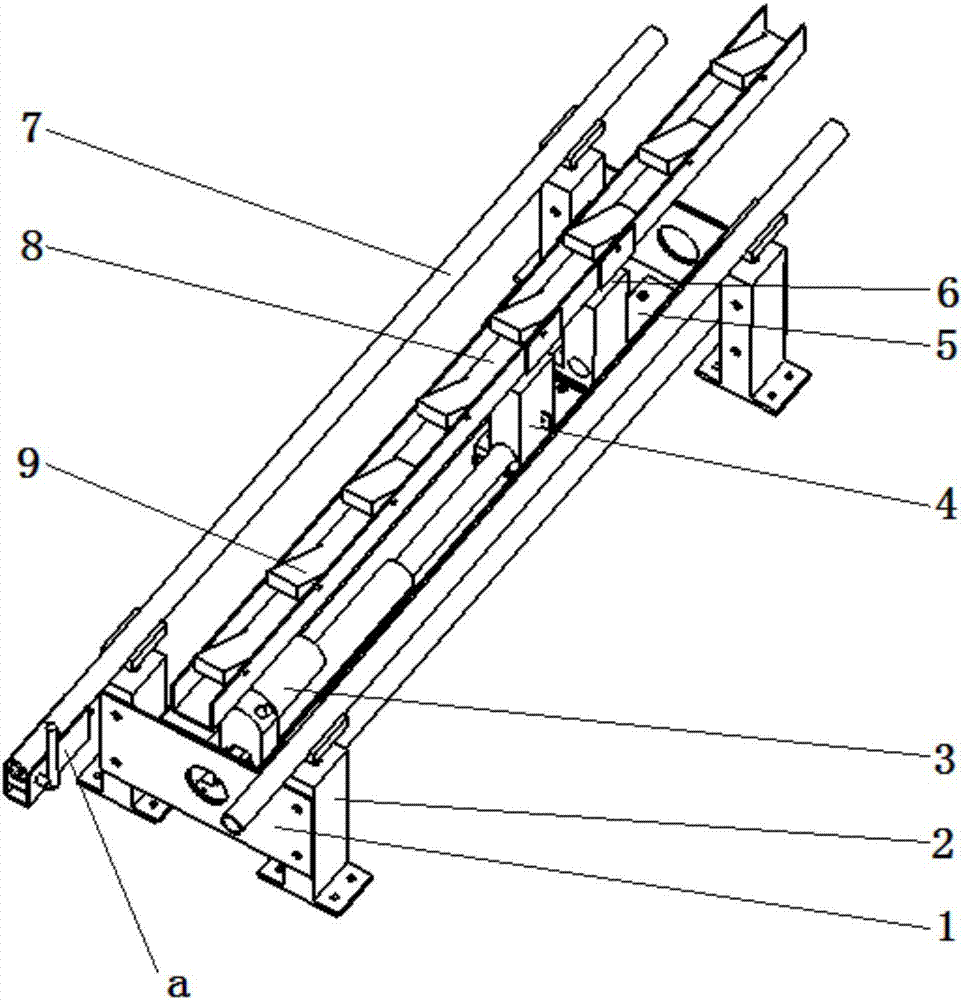

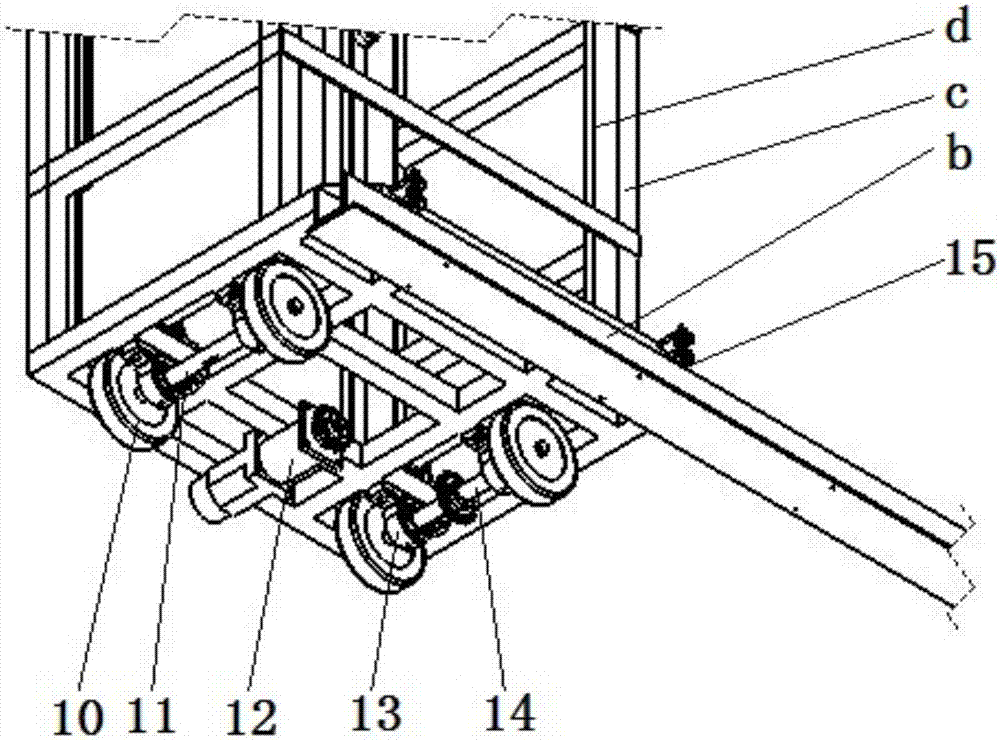

[0039] A multi-layer three-dimensional automatic mobile seedbed system, such as Figure 1-7 As shown, it includes a cultivation unit A and a mobile unit B. The cultivation unit A includes a single seedbed C and a driving device D, and the mobile unit B includes a lifting platform device E, a sprocket mechanism F, a wheel train mechanism G and a sensor positioning device. The sensing positioning device includes a first sensing positioning device, a second sensing positioning device, a third sensing positioning device and a fourth sensing positioning device. The first sensing positioning device is installed on the guide rail b on the ground, and the second sensing positioning device The sensor positioning device is installed on the front of the vertical support rod 2 and the pushing pillar 20 of the secondary push unit, and the third sensor positioning device is installed on the front of the alignment mechanism a arranged at the end of the sliding support rod and is arranged with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com