System and method for promoting coal fly ash to adsorb and remove pollutants such as mercury in flue gas

A technology for pollutants and fly ash, which is applied in the field of pollutant adsorption and removal systems, can solve the problems of secondary release, high operating cost of adsorption and mercury removal technology, and the impact of comprehensive utilization of fly ash, and achieves good adsorption and removal of mercury. The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

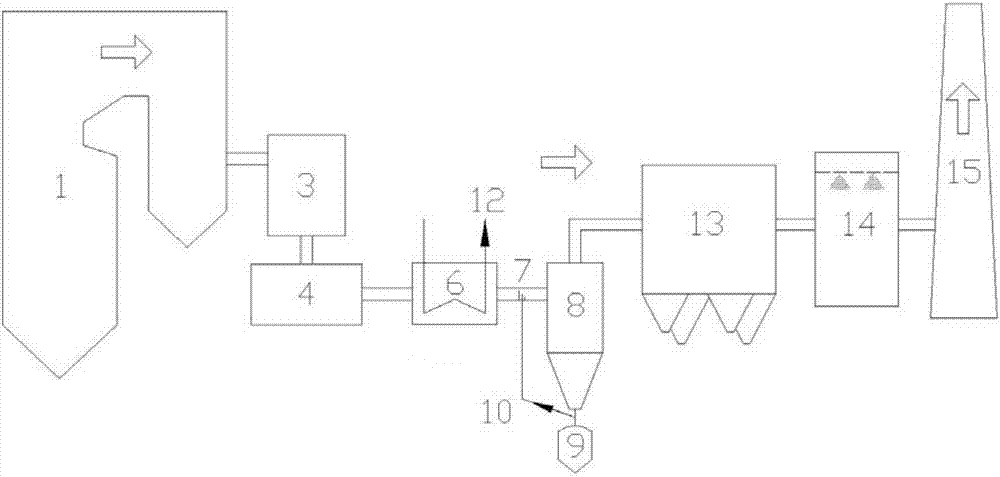

[0035] Such as figure 1 As shown, in this embodiment, a cyclone separator 8 is added at the entrance of the original dust collector 13 in the coal-fired power plant, and the residence time of fly ash in the flue gas is increased through the cyclone separator 8 . At the entrance of the cyclone separator 8, a flue gas cooler 6 is provided for reducing the temperature of the flue gas and recycling the working medium 12 which has absorbed the heat of the flue gas. At the same time, the cyclone separator 8 is used to capture the large particle size fly ash with a high carbon content > 80 μm, and a part of the large particle size fly ash is sent back to the inlet flue of the cyclone separator 8 through the fly ash conveying system 10 7. Another part of fly ash with large particle size enters the fly ash bin 9.

[0036] The characteristics of this embodiment are: it is not combined with oxidative mercury removal technology and activated carbon adsorption mercury removal technology, ...

Embodiment 2

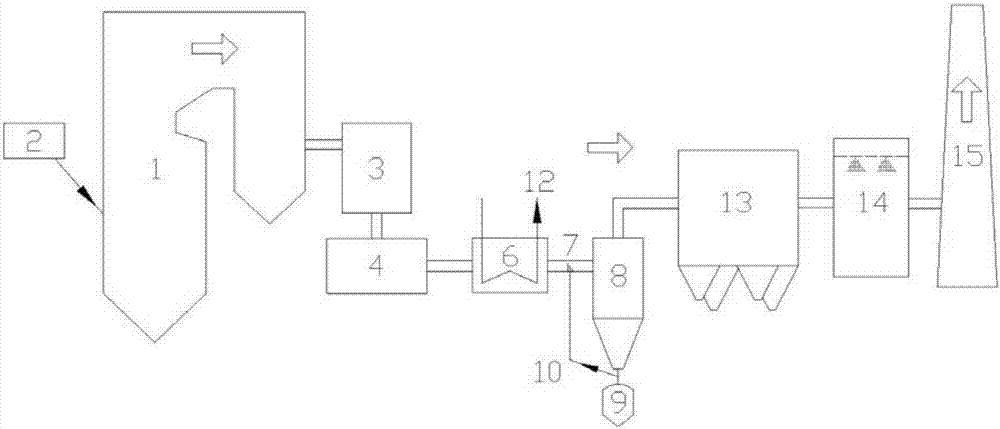

[0038] Such as figure 2 As shown, in this embodiment, a cyclone separator 8 is added at the entrance of the original dust collector 13 in the coal-fired power plant, and the residence time of fly ash in the flue gas is increased through the cyclone separator 8 . At the entrance of the cyclone separator 8, a flue gas cooler 6 is provided for reducing the temperature of the flue gas and recycling the working medium 12 which has absorbed the heat of the flue gas. At the same time, the cyclone separator 8 is used to capture the large particle size fly ash with a high carbon content > 80 μm, and a part of the large particle size fly ash is sent back to the inlet flue of the cyclone separator 8 through the fly ash conveying system 10 7. Another part of fly ash with large particle size enters the fly ash bin 9.

[0039] The forced oxidant 2 and the catalytic oxidant 3 are used to increase the proportion of gaseous divalent mercury in the flue gas, and the gaseous divalent mercury i...

Embodiment 3

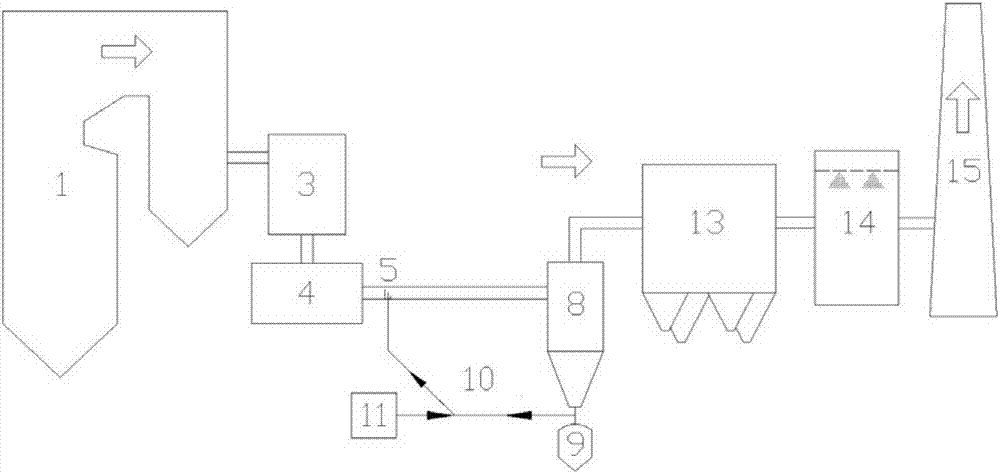

[0042] Such as image 3 As shown, in this embodiment, a cyclone separator 8 is added at the entrance of the original dust collector 13 in the coal-fired power plant, and the residence time of fly ash in the flue gas is increased through the cyclone separator 8 . At the same time, the cyclone separator 8 is used to capture the large particle size fly ash with a high carbon content > 150 μm, and a part of the large particle size fly ash is sent back to the inlet flue of the cyclone separator 8 through the fly ash conveying system 10 7. Another part of fly ash with large particle size enters the fly ash bin 9.

[0043] A certain amount of activated carbon is added into the fly ash conveying system 10 through the activated carbon bin 11, and the activated carbon is sent back to the outlet flue 5 of the air preheater 4 together with the large particle size fly ash. The particle size of the activated carbon used is 200 μm, so that most of the activated carbon used can also be captu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com