Surface enhanced rare earth high-carbon chrome steel for high-speed rails, and production technology thereof

A high-carbon chromium steel, surface strengthening technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of uneven thickness of the surface carbide layer, poor comprehensive performance, etc., to achieve high surface hardness and Reasonable matching of high toughness, improving wear resistance and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

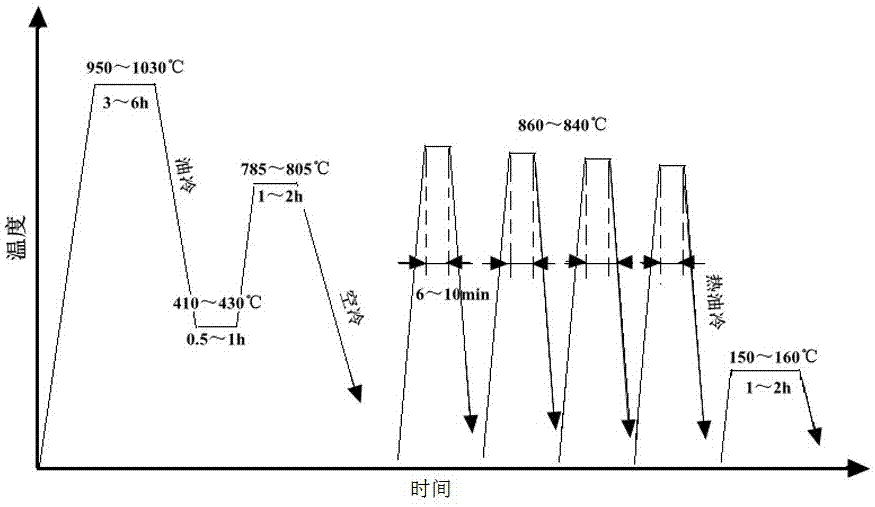

[0022] A preparation process for surface-strengthened rare earth high-carbon chromium steel for high-speed iron, including placing GCr15 steel parts in a closed salt bath furnace containing rare earth and aluminum powder in a neutral molten salt, passing metal atoms in the molten salt and steel parts matrix The carbon and nitrogen atoms in the steel react chemically and diffuse on the surface of the steel substrate to form a metal carbide layer containing rare earth elements. The rare earth elements described in the present invention are yttrium and neodymium, which can be added as a single element, or two kinds can be mixed and added at the same time. In the form of chlorides of yttrium and neodymium.

[0023] A salt bath process for preparing rare earth high-carbon chromium steel of the present invention, the process comprises the following steps:

[0024] (1) Substrate pretreatment: put the GCr15 steel parts into methanol or gasoline for cleaning, and then polish the surfa...

Embodiment 1

[0034] The surface-strengthened rare-earth high-carbon chromium steel described in this embodiment is infiltrated with yttrium and neodymium metals on the surface of the GCr15 steel substrate through a molten salt bath to form a metallic carbon layer containing yttrium and neodymium. Its salt bath process is:

[0035] (1) Substrate pretreatment: Put the GCr15 steel parts into methanol for cleaning, and then polish the surface of the cleaned GCr15 steel parts to obtain the pretreated substrate for later use;

[0036] (2) Preparation of molten salt: the distribution ratio of the molten salt is Al-BaCl 2 -NaCl-NaF-YCl 3 -NdCl 3 , wherein the mass fraction of Al powder is 3%, the mass fraction of NaF is 7%, the mass fraction of NaCl is 6.875%, and the mass fraction of BaCl 2 The mass fraction of YCl is 48.125%. After the molten salt is melted at 830°C, YCl with a mass fraction of 15% is added respectively. 3 and NdCl with a mass fraction of 20% 3 , keep warm for 3h, get molte...

Embodiment 2

[0041] The surface-strengthened rare-earth high-carbon chromium steel described in this embodiment is infiltrated with yttrium and neodymium metals on the surface of the GCr15 steel substrate through a molten salt bath to form a metallic carbon layer containing yttrium and neodymium. Its salt bath process is:

[0042] (1) Substrate pretreatment: Put the GCr15 steel parts into gasoline for cleaning, and then polish the surface of the cleaned GCr15 steel parts to obtain the pretreated substrate for later use;

[0043] (2) Preparation of molten salt: the distribution ratio of the molten salt is Al-BaCl 2 -NaCl-NaF-YCl 3 -NdCl 3 , wherein, the mass fraction of Al powder is 4%, the mass fraction of NaF is 8%, the mass fraction of NaCl is 5.34%, the mass fraction of BaCl 2 The mass fraction of YCl is 42.66%. After the molten salt is melted at 830°C, YCl with a mass fraction of 17.5% is added 3 and NdCl with a mass fraction of 22.5% 3 , keep warm for 2h, get molten salt, and set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeable layer thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap