Composite sound absorption structure based on combination of micro-perforated board with acoustic metamaterial

An acoustic metamaterial and micro-perforated plate technology, which is applied in the direction of sound-producing instruments, instruments, etc., to achieve the effect of improving the production process, increasing the number, and being easy to process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

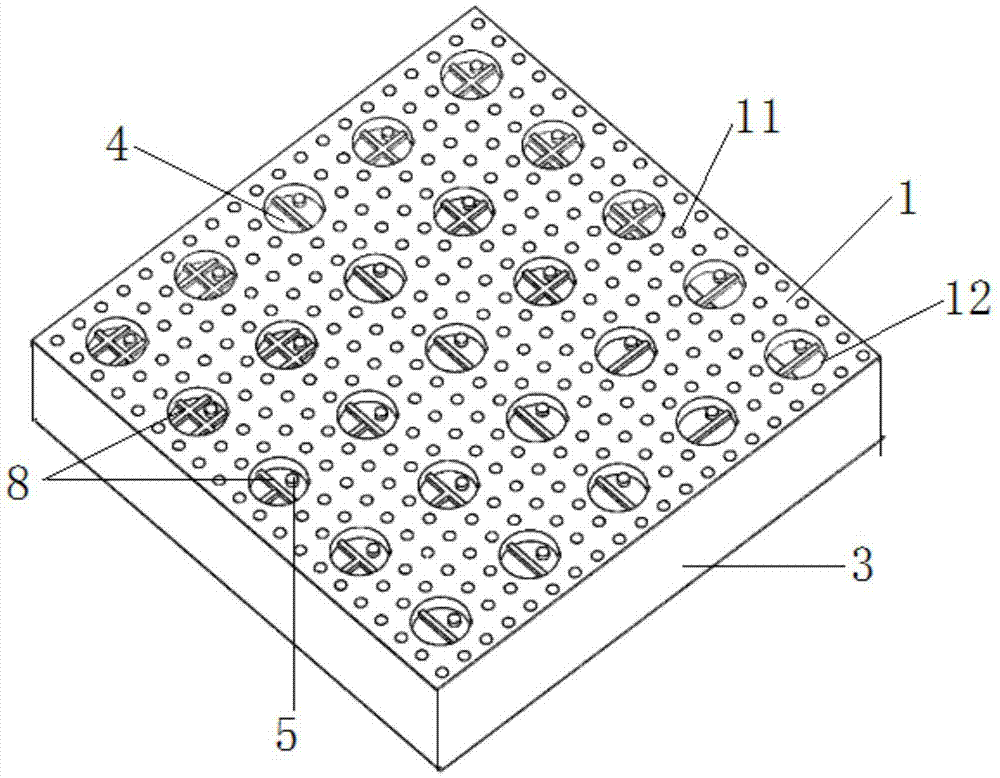

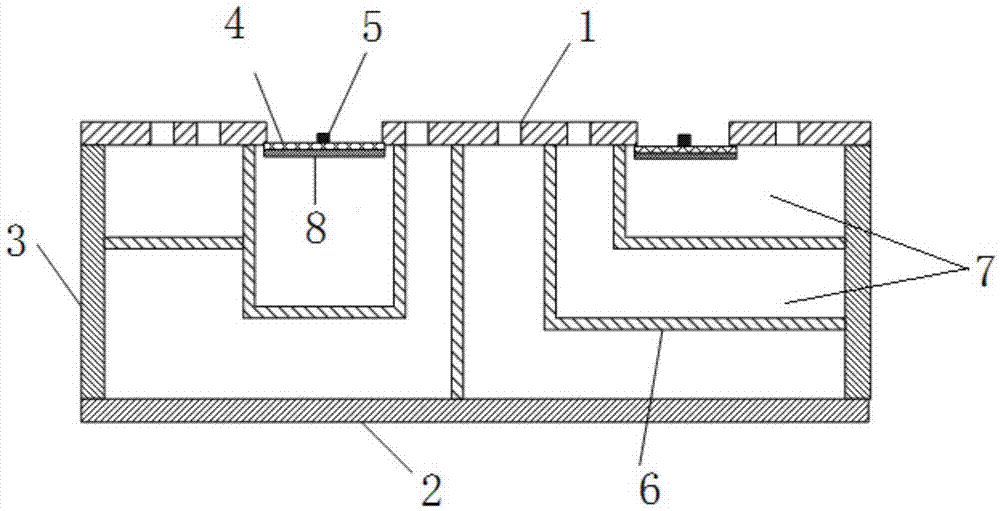

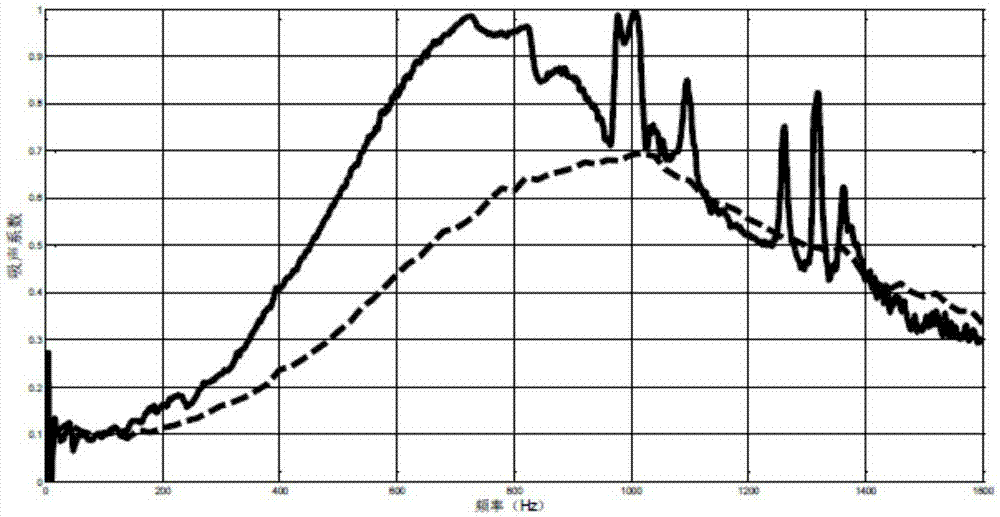

[0035] image 3 The aperture tested for the impedance tube is d=0.8mm, the perforation rate is 2%, the micro-perforated plate structure (shown by the dotted line curve in the figure) and the micro-perforated plate combined with the acoustic metamaterial composite sound-absorbing structure (Fig. Indicated by the solid line curve) in the sound absorption performance comparison curve in the case of cavity depth H=50mm, the micro-perforated plate combined with the acoustic metamaterial composite sound-absorbing structure has a unit hole with a diameter of D=50mm in the middle of the micro-perforated plate , the spacer divides the unit hole into 9 small areas arranged aperiodically, the film material is pasted on the spacer, and the quality block is fixed on the film unit. from image 3 From the sound absorption performance curve, we can see that the composite structure of the micro-perforated plate combined with the thin-film acoustic metamaterial has better sound absorption perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com