Low GI (glycemic index) noodle and preparation method thereof

A noodle and dough technology, which is applied in the field of food processing, can solve problems such as low dietary fiber content, single raw material, and difficult quality control, and achieve the effects of supplementing dietary fiber, controlling blood sugar peaks, and improving intestinal health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

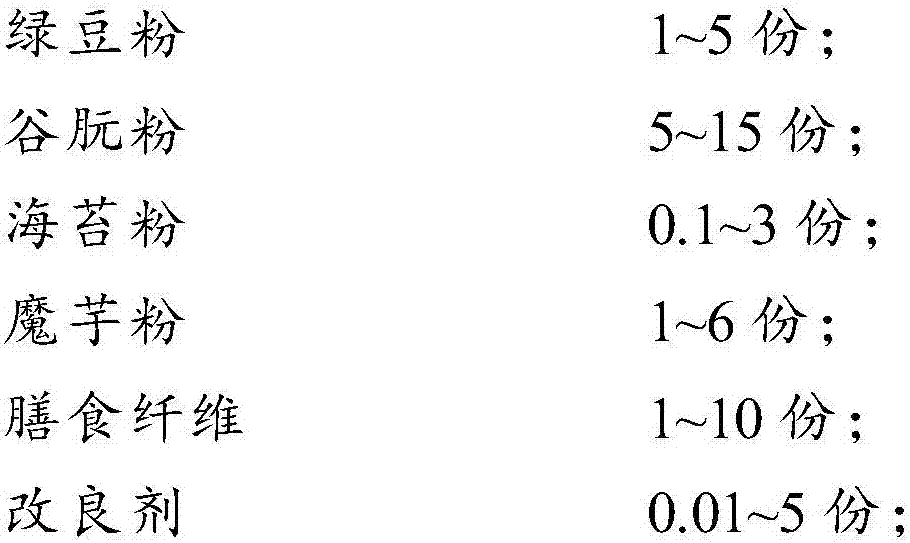

Method used

Image

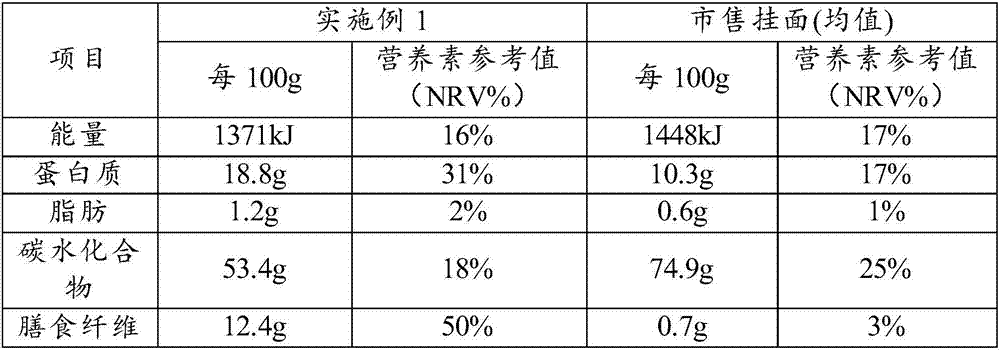

Examples

Embodiment 1

[0052] (1) Make 7kg of buckwheat flour, 2kg of wheat dietary fiber, 10kg of tartary buckwheat flour, 2kg of soybean flour, 1kg of mung bean flour, 8kg of gluten powder, 0.1kg of seaweed powder, 2kg of konjac flour, and 2kg of resistant dextrin to make a mixture 1 for later use ;

[0053] (2) 0.9kg of sodium chloride is dissolved in water to make brine for subsequent use;

[0054] (3) Mix the mixture 1 with 65 kg of wheat flour for 5-10 minutes, add salt water, stir for 15-30 minutes, and make dough;

[0055] (4) The dough is allowed to stand and mature for 10-20 minutes, and then rolled (4-7 steps) to make noodle strips;

[0056] (5) Use No. 18-22 round knife or square knife to cut into noodles, cut to fixed length;

[0057] (6) Put the noodles into a drying room at 70-85°C for 6-8 hours to dry, or dry them naturally indoors.

[0058] (7) Cut the air-dried noodles into strips, weigh and pack.

[0059] (8) Testing and storage of finished products.

Embodiment 2

[0061] (1) Mix 5kg of buckwheat flour, 1.5kg of wheat dietary fiber, 15kg of tartary buckwheat flour, 3kg of soybean flour, 1kg of mung bean flour, 11kg of gluten powder, 2kg of seaweed powder, 1kg of konjac flour, and 0.49kg of resistant dextrin to make mixture 1 spare;

[0062] (2) Sodium chloride 0.01kg is dissolved in water to make brine for subsequent use;

[0063] (3) Mix the mixture 1 with 60 kg of wheat flour for 5-10 minutes, then add salt water, stir for 15-30 minutes, and make dough;

[0064] (4) The dough is allowed to stand and mature for 10-20 minutes, and then rolled (4-7 steps) to make noodle strips;

[0065] (5) Use No. 18-22 round knife or square knife and form noodles, cut to fixed length;

[0066] (6) Put the noodles into a drying room at 70-85°C for 6-8 hours to dry, or dry them naturally indoors.

[0067] (7) Cut the air-dried noodles into strips, weigh and pack.

[0068] (8) Testing and storage of finished products.

Embodiment 3

[0070] (1) 5kg of buckwheat flour, 1kg of wheat dietary fiber, 10kg of tartary buckwheat flour, 1kg of soybean flour, 1kg of mung bean flour, 15kg of gluten powder, 2kg of seaweed powder, and 5kg of konjac flour are made into mixture 1 for subsequent use;

[0071] (2) 2 kg of sodium chloride is dissolved in water to prepare brine for subsequent use;

[0072] (3) Mix mixture 1 and 58 kg of wheat flour for 5-10 minutes, add salt water, stir for 15-30 minutes, and make dough;

[0073] (4) The dough is allowed to stand and mature for 10-20 minutes, and then rolled (4-7 steps) to make noodle strips;

[0074] (5) Use No. 18-22 round knife or square knife and form noodles, cut to fixed length;

[0075] (6) Send the noodles into a drying room at 70-85°C for 6-8 hours until dry, or air-dry indoors naturally.

[0076] (7) Cut the air-dried noodles into strips, weigh and pack.

[0077] (8) Testing and storage of finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com