A beta-hemihydrate gypsum retarder and a preparing method thereof

A technology of hemihydrate gypsum and retarder, which is applied in the field of building materials, can solve the problems of complex preparation process, high production cost, single effect of retarder, etc., and achieve the effect of simple preparation process, low cost and small loss of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

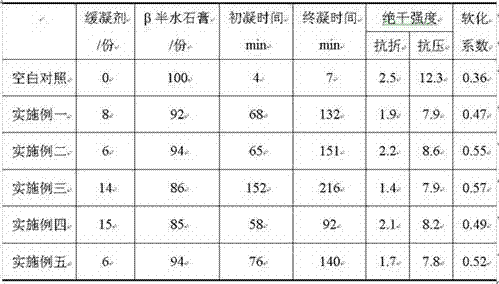

Embodiment 1

[0021] Manganese slag is dried and ground to make manganese slag powder (specific surface area 458m 2 / kg); mix 6 parts of zeolite (200 mesh), 7 parts of manganese slag powder, and 1 part of slag portland cement to obtain retarder.

[0022] 92 parts of β-hemihydrate gypsum and 8 parts of retarder are made into a mixture with a water-to-material ratio of 0.60, molded, and tested for setting time and strength properties.

Embodiment 2

[0024] Dry and grind 4 parts of manganese slag, 5 parts of steel slag and 3 parts of slag to make metallurgical slag powder (specific surface area 458m 2 / kg); Mix 2 parts of zeolite (300 mesh), 4 parts of metallurgical slag powder, and 2 parts of ordinary Portland cement to obtain retarder.

[0025] 94 parts of β-hemihydrate gypsum and 6 parts of retarder are made into a mixture with a water-to-material ratio of 0.61, molded, and tested for setting time and strength properties.

Embodiment 3

[0027] 86 parts of β-hemihydrate gypsum and 14 parts of the retarder obtained in Example 2 were made into a mixture with a water-to-material ratio of 0.59, molded, and tested for setting time and strength properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com