Continuous oscillation flow pipe type cooling crystallization method of erythritol

A technology of erythritol and cooling crystallization, which is applied in the field of continuous oscillating flow tube cooling crystallization of erythritol, can solve the problems of blocked tube crystallizer, crystal breaking, crystal precipitation, etc. mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

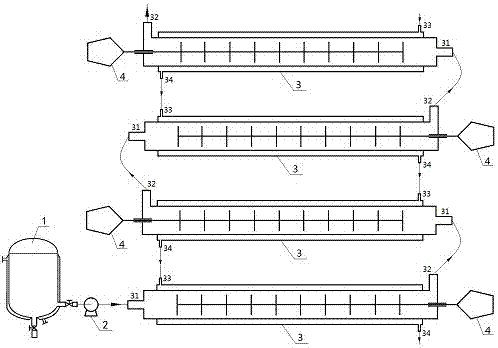

[0022] Such as figure 1 Shown, the continuous oscillating flow tube type cooling crystallization method of erythritol involved in the present invention is characterized in that, specifically completes according to the following steps:

[0023] Step 1. Under the conditions of 40-80°C and a rotational speed of 100-500r / min, mix the crude erythritol with water in the crystallization mother liquid storage tank (1) to prepare erythritol with a concentration of 50-80wt% crystallization mother liquor;

[0024] Step 2. After filtering the erythritol crystallization mother liquor configured in step 1 to remove solid insoluble matter, send it into the tubular crystallizer group with a pump (2). device (3), the number of series series n=4; the tubular crystallizer group is composed of multi-stage series series casing type crystallizers (3), the series series number n=4; the casing type crystallizer ( 3) A tube-side inlet (31), a tube-side outlet (32), a shell-side inlet (33) and a shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com