A kind of preparation method of hydroxytyrosol

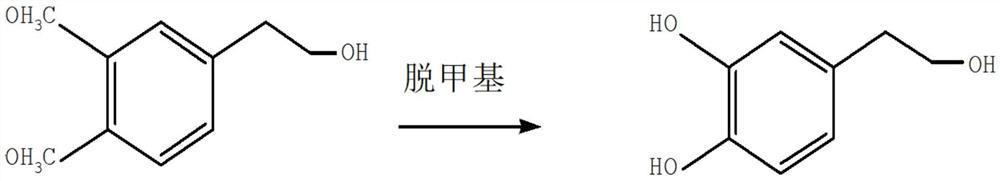

A technology of hydroxytyrosol and ethanol, which is applied in the field of chemical synthesis of natural product hydroxytyrosol, can solve the problems of poor product quality, low yield, and unsuitability for industrial production, and achieve good color, high demethylation activity, and increased Effect of demethylation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of embodiment 1 hydroxytyrosol

[0025] At room temperature, put 115g of acetonitrile, 45.5g of 3,4-dimethoxyphenethyl alcohol, and 204g of aluminum triiodide into a dry 1000ml four-necked reaction flask, stir well, control the temperature at 10-15°C, drop Add 4 g of boron trifluoride tetrahydrofuran, drop it off, raise the temperature to reflux, and check the liquid phase after 6 hours, the reaction is complete. Cool down to room temperature, filter, add 10 g of activated carbon to the filtrate, reflux for 0.5 h, filter, recover the filtrate to dryness, and obtain a light yellow oily residue. Add 80g of dichloromethane, reflux for 2h, and slowly lower to room temperature for beating for 2h. Filter and dry to obtain 36.6g of white powdery solid, melting point 80-82°C, content above 98%, yield 95.5%.

[0026] The conditions for liquid phase detection are: Instrument: Shimadzu CTO-15C

[0027] Column: LunaC18, 4.6mm×250mm, 5μm

[0028] Mobile phase: wa...

Embodiment 2

[0032] The preparation of embodiment 2 hydroxytyrosol

[0033] At room temperature, put 140g of acetonitrile, 45.5g of 3,4-dimethoxyphenethyl alcohol, and 234g of aluminum triiodide into a dry 1000ml four-necked reaction flask, stir well, control the temperature at 10-15°C, drop Add 4.6 g of boron trifluoride tetrahydrofuran, drop it off, raise the temperature to reflux, and check the liquid phase after 5 hours, the reaction is complete. Cool down to room temperature, filter, add 10 g of activated carbon to the filtrate, reflux for 0.5 h, filter, and recover the filtrate to dryness to obtain a light yellow oily residue. Add 80g of dichloromethane, reflux for 2h, and slowly lower to room temperature for beating for 2h. Filtrate and dry to obtain 37.2 g of white powdery solid, with a melting point of 80-82° C., a content of more than 98%, and a yield of 96.8%.

[0034] (liquid phase detection condition is the same as embodiment 1)

Embodiment 3

[0035] The preparation of embodiment 3 hydroxytyrosol

[0036] At room temperature, put 180g of acetonitrile, 45.5g of 3,4-dimethoxyphenethyl alcohol, and 285g of aluminum triiodide into a dry 1000ml four-necked reaction flask, stir well, control the temperature at 10-15°C, drop Add 5.7 g of boron trifluoride diethyl ether, drop it off, raise the temperature to reflux, and check the liquid phase after 4 hours, the reaction is complete. Cool down to room temperature, filter, and recover the solvent from the filtrate to dryness, add 150g of ethanol and 10g of activated carbon to the residue, reflux for 0.5h, filter, recover the filtrate to dryness, add 70g of dichloromethane to the residue, reflux for 2h, slowly lower to room temperature and beat for 2h . Filter and dry to obtain 36g of white powdery solid, melting point 80-82°C, content above 98%, yield 93.5%. (liquid phase detection condition is the same as embodiment 1)

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com