Method for preparing edible grade transparent concentrated soybean phospholipid

A soybean lecithin, edible-grade technology, applied in the field of oil processing, can solve the problems of dark color and poor transparency of concentrated soybean lecithin, and achieve the effect of solving the dark color and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

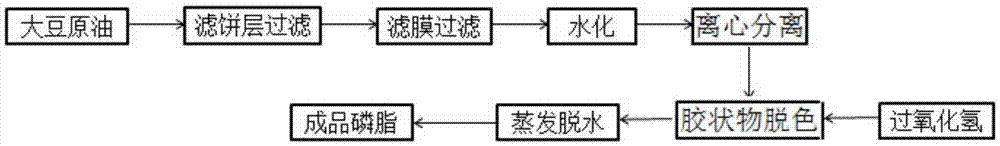

Image

Examples

Embodiment 1

[0033] Using soybean crude oil as a raw material, the soybean crude oil is filtered through a cellulose filter cake layer, wherein the amount of cellulose is 0.01% of the weight of the soybean crude oil, and then filtered through a filter membrane with a pore size of 20 μm. Add water equivalent to 0.1% of the weight of soybean crude oil to the filtered soybean crude oil, carry out hydration reaction for 5 minutes, and the reaction temperature is 30° C., and the phospholipids in the soybean crude oil and water form a jelly. Centrifuge at a centrifugal speed of 2500 rpm for 10 min to obtain a jelly after centrifugation, add hydrogen peroxide equivalent to 0.1% of its weight to the jelly after centrifugation, and carry out a decolorization reaction at a temperature of 20 °C, the decolorization time is 5min, and the decolorized product is obtained. Then, the decolorized product is evaporated and dehydrated, the temperature is controlled at 90°C, the vacuum degree of evaporation is...

Embodiment 2

[0035]Using soybean crude oil as a raw material, the soybean crude oil is filtered through a cellulose filter cake layer, wherein the amount of cellulose is 5% of the weight of the soybean crude oil, and then filtered through a filter membrane with a pore size of 0.6 μm. Water corresponding to 10% of the weight of soybean crude oil was added to the filtered soybean crude oil, and the hydration reaction was carried out for 60 minutes at a reaction temperature of 90.2° C., and the phospholipids in the soybean crude oil and water formed a jelly. Centrifuge at a centrifugal speed of 2500 rpm for 10 min to obtain a jelly after centrifugation, add hydrogen peroxide equivalent to 5% of its weight to the jelly after centrifugation, and carry out a decolorization reaction at a temperature of 80 °C, the decolorization time was 180min, and the decolorized product was obtained. Then, the decolorized product is evaporated and dehydrated, the temperature is controlled at 90°C, the evaporati...

Embodiment 3

[0037] Using soybean crude oil as a raw material, the soybean crude oil is filtered through a cellulose filter cake layer, wherein the amount of cellulose is 0.2% of the weight of the soybean crude oil, and then filtered through a filter membrane with a pore size of 3 μm. Water corresponding to 1% of the weight of soybean crude oil is added to the filtered soybean crude oil, and the hydration reaction is carried out for 20 minutes at a reaction temperature of 40° C., and the phospholipids in the soybean crude oil and water form a jelly. Centrifuge at a centrifugal speed of 2500 rpm for 10 min to obtain a jelly after centrifugation, add hydrogen peroxide equivalent to 0.5% of its weight in the jelly after centrifugation, and carry out a decolorization reaction at a temperature of 30 °C, the decolorization time is 30min, and the decolorized product is obtained. Then, the decolorized product is evaporated and dehydrated, the temperature is controlled at 90°C, the vacuum degree of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com