Light-cured resin and application thereof

A light-curing resin and application technology, applied in the preparation of test samples, instruments, analysis materials, etc., can solve the problems of long time for collodion coagulation, easy deformation of fibers, unfavorable fiber types, etc., and achieves rapid film formation. Controllable, high fiber dispersion, easy to obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

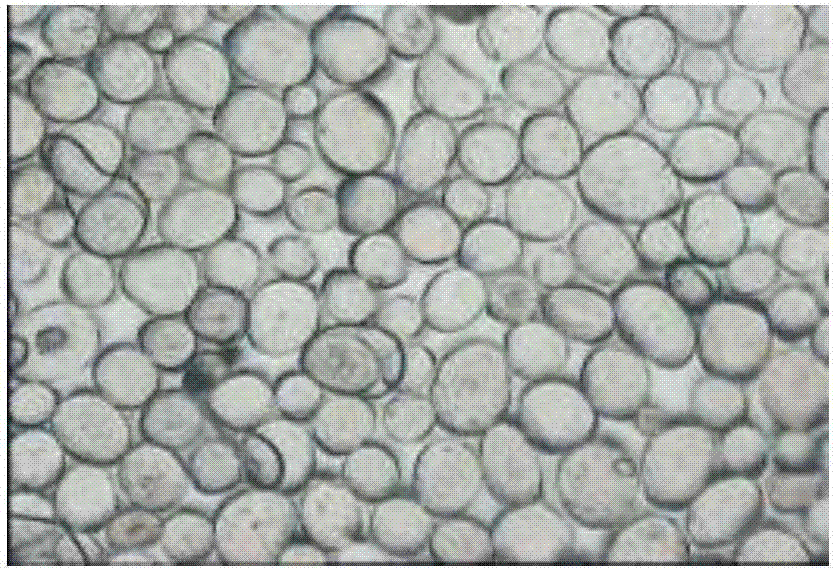

Embodiment 1

[0036] A kind of photocurable resin of this embodiment is composed of the following components by mass percentage:

[0037]

[0038] The specific steps of using the photocurable resin prepared in this embodiment to make fiber cross-section slices are as follows:

[0039] 1) Put the fiber bundles neatly into the fiber slicer, cut off the exposed fibers with a sharp blade, then install the spring device, slightly rotate the precision screw to make the fiber bundles protrude from the metal bottom surface of the fiber slicer, and place The exposed fiber is cut off, and then the precision screw is slightly rotated to expose the fiber bundle;

[0040] 2) Coating a layer of the photocurable resin on the exposed fibers, and then irradiating for 10 seconds under an ultraviolet lamp with a wavelength of 320-400nm until the photocurable resin is dry;

[0041] 3) Slice with a sharp blade, discard the first knife, and slice again with a sharp blade (cutting edge thickness is 0.01mm), t...

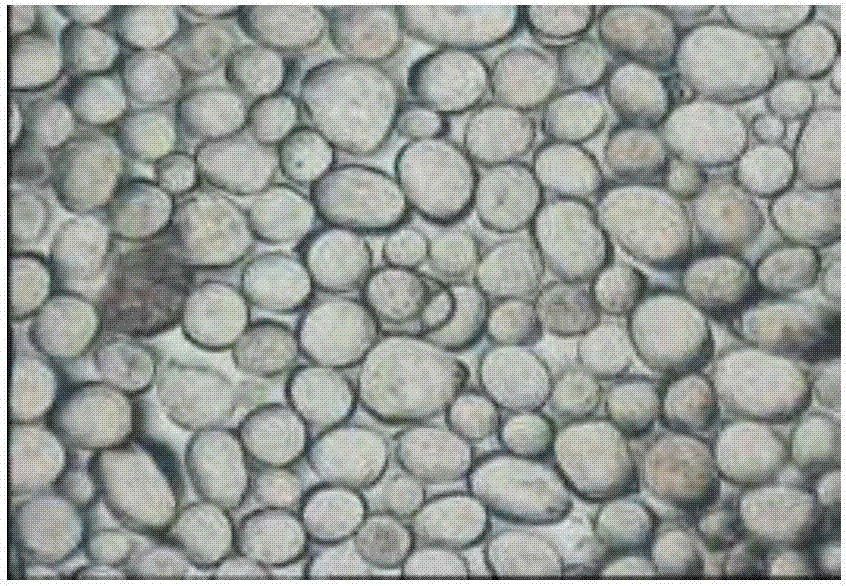

Embodiment 2

[0044] A kind of photocurable resin of this embodiment is composed of the following components by mass percentage:

[0045]

[0046] The specific steps of using the photocurable resin prepared in this embodiment to make fiber cross-section slices are as follows:

[0047] 1) Put the fiber bundles neatly into the fiber slicer, cut off the exposed fibers with a sharp blade, then install the spring device, slightly rotate the precision screw to make the fiber bundles protrude from the metal bottom surface of the fiber slicer, and place The exposed fiber is cut off, and then the precision screw is slightly rotated to expose the fiber bundle;

[0048] 2) Coating a layer of the photocurable resin on the exposed fibers, and then irradiating for 15 seconds under an ultraviolet lamp with a wavelength of 320-400nm until the photocurable resin is dry;

[0049] 3) Slice with a sharp blade, discard the first knife, and slice again with a sharp blade (cutting edge thickness is 0.01mm), t...

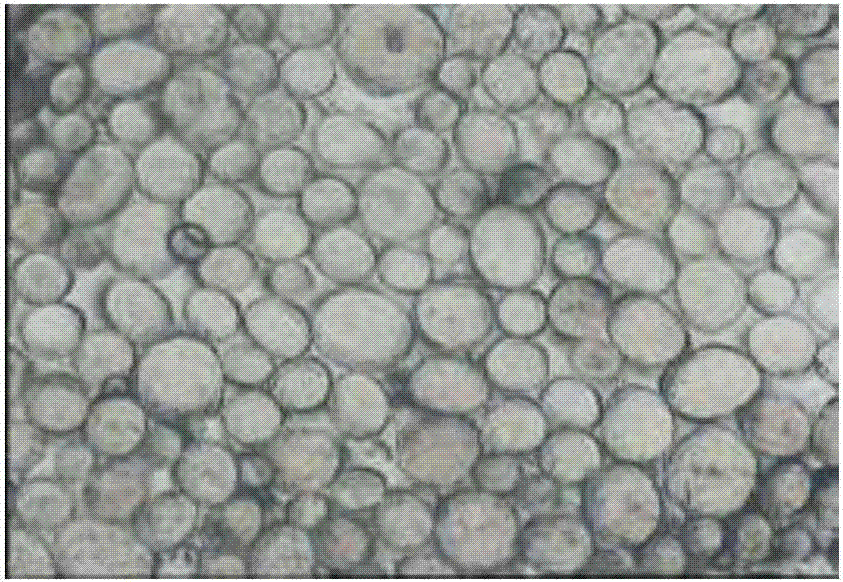

Embodiment 3

[0052] A kind of photocurable resin of this embodiment is composed of the following components by mass percentage:

[0053]

[0054]The specific steps of using the photocurable resin prepared in this embodiment to make fiber cross-section slices are as follows:

[0055] 1) Put the fiber bundles neatly into the fiber slicer, cut off the exposed fibers with a sharp blade, then install the spring device, slightly rotate the precision screw to make the fiber bundles protrude from the metal bottom surface of the fiber slicer, and place The exposed fiber is cut off, and then the precision screw is slightly rotated to expose the fiber bundle;

[0056] 2) Coating a layer of the photocurable resin on the exposed fibers, and then irradiating for 15 seconds under an ultraviolet lamp with a wavelength of 320-400nm until the photocurable resin is dry;

[0057] 3) Slice with a sharp blade, discard the first knife, and slice again with a sharp blade (cutting edge thickness is 0.02mm), ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com