Preparation method and application of fluorosilicon antifouling and antifingerprint resin for touch screen glass

An anti-fingerprint and touch screen technology, applied in anti-fouling/underwater coatings, biocide-containing paints, coatings, etc., to achieve good anti-fouling and anti-fingerprint effects and smooth glass surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

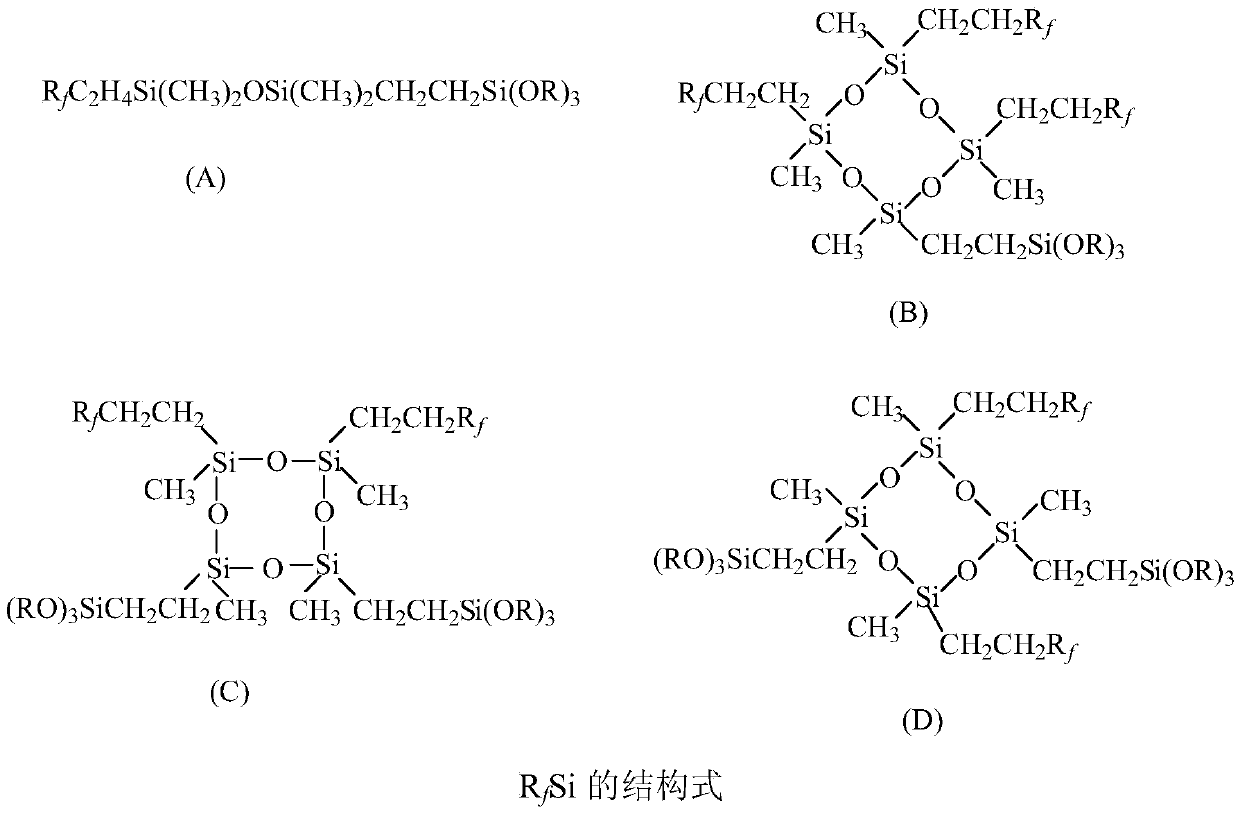

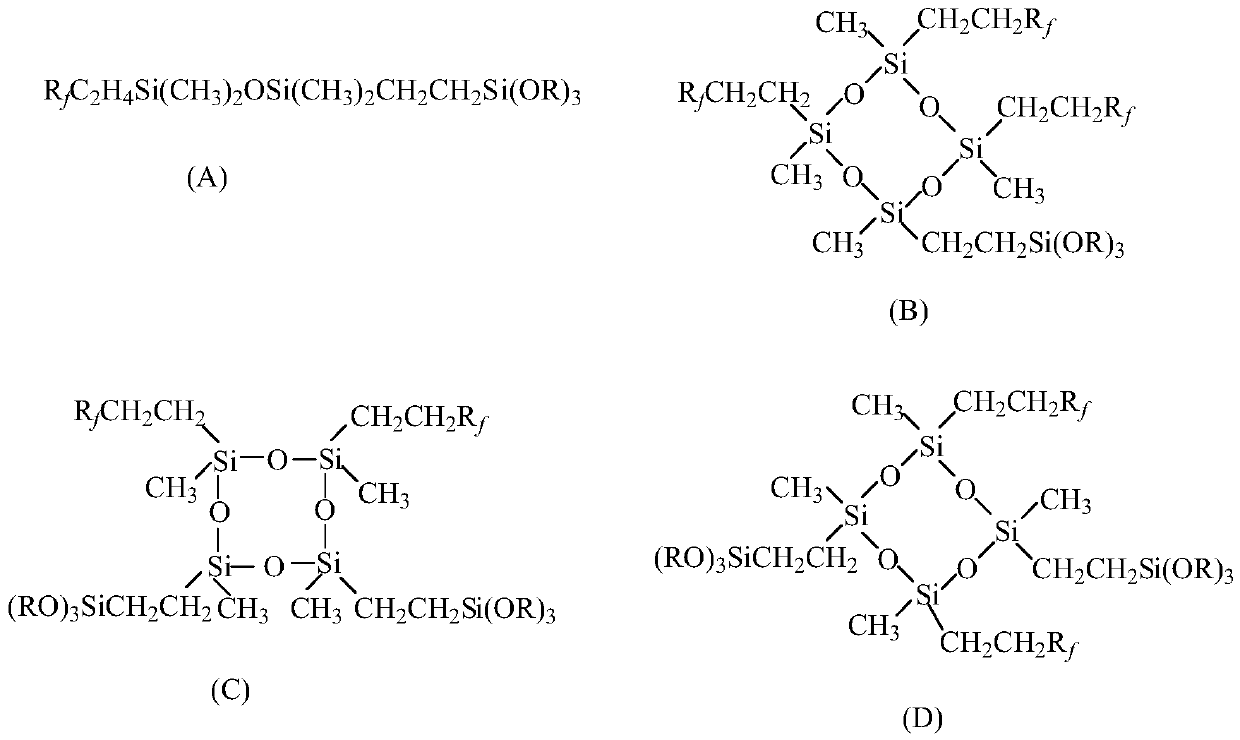

[0031] (1) Reactive perfluoroalkyl-substituted alkoxysiloxane oligomer R f Synthesis of Si-1

[0032] In a 50mL three-necked flask equipped with a reflux condenser, a thermometer, and a stirrer, 4.46g (0.01mol) of heptadecafluoro-1-decene (R f17 V), 1.90g (0.01mol) vinyltriethoxysilane (MTES) and 1.34g (0.01mol) tetramethyldisiloxane (D 2 H, containing Si-H 0.02mol, a hydrogen-containing siloxane oligomer with a Si-H bond functionality of 2) mixed [n(R f17 V): n(MTES):n(Si-H) molar ratio=1:1:2], mechanical stirring and mixing, heating to 70°C, then adding 50ppm complex platinum catalyst KP22 at 70°C for 10h, then Under the conditions of absolute pressure of 60mmHg and temperature of 90°C, decompression and low boiling for 10 minutes, a light brown transparent liquid is obtained, that is, the structure is shown in formula (A), R=-C 2 h 5 , R f =-C 8 f 17 The perfluoroalkyl-substituted alkoxysiloxane oligomer——1-heptadecafluorodecylethyl-2-(triethoxysilylethyl)tetramethyl...

Embodiment 2

[0039] (1) Reactive perfluoroalkyl-substituted alkoxysiloxane oligomer R f Synthesis of Si-2

[0040] In a 50mL three-necked bottle equipped with a reflux condenser, a thermometer, and a stirrer, accurately weigh 13.38g (0.03mol) of heptadecafluoro-1-decene (R f17 V), 1.90g (0.01mol) vinyltriethoxysilane (MTES) and 24.05g (0.01mol) tetramethylcyclotetrasiloxane (D 4 H , containing Si-H 0.04mol, a hydrogen-containing siloxane oligomer with a Si-H bond functionality of 4) mixed [n(R f17 V): n(MTES):n(Si-H) molar ratio=3:1:4], mechanical stirring and mixing, heating to 90°C, then adding 100ppm complex platinum catalyst KP22 to react at 90°C for 6h, then With an absolute pressure of 260mmHg and a temperature of 90°C, decompression and low boiling for 30 minutes, a light brown transparent liquid is obtained, that is, the structure is shown in formula (B), R=-C 2 h 5 , R f =-C 8 f 17 Perfluoroalkyl substituted alkoxysiloxane oligomers——1-triethoxysilylethyl-3,5,7-tri(heptade...

Embodiment 3

[0047] (1) Reactive perfluoroalkyl-substituted alkoxysiloxane oligomer R f Synthesis of Si-3

[0048] In a 50mL three-necked bottle equipped with a reflux condenser, a thermometer, and a stirrer, accurately weigh 6.92g (0.02mol) of perfluorohexylethylene (R f13 V), 2.96g (0.02mol) vinyltrimethoxysilane (MTMS) and 24.05g (0.01mol) tetramethylcyclotetrasiloxane (D 4 H , containing Si-H 0.04mol, a hydrogen-containing siloxane oligomer with a Si-H bond functionality of 4) mixed [n(R f13 V): n(MTMS):n(Si-H) molar ratio=2:2:4], mechanical stirring and mixing, heating to 85°C, and then adding 80ppm complex platinum catalyst KP22 (divinyltetramethyl Platinum disiloxane) was reacted at 85°C for 12h, and then decompressed and deboiled for 15min at an absolute pressure of 210mmHg and a temperature of 85°C to obtain a light brown transparent liquid with structures such as formulas (C) and (D) Shown, R=-CH 3 , R f =-C 6 f 13 The perfluoroalkyl-substituted alkoxysiloxane oligomer - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com