Konjak gulcomannan closestool gasket and preparation method thereof

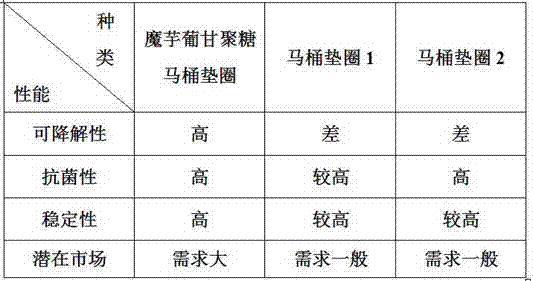

A glucomannan toilet and gasket technology, applied in the field of daily necessities, can solve the problems of difficult molding of toilet gasket materials, high requirements on manufacturing precision, poor material degradability, etc., and achieves good antifouling performance, low cost, and improved product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, a kind of preparation method of konjac glucomannan toilet seat, comprises the following steps:

[0019] (1) Preparation of carboxymethylated mung bean starch: According to the mass components, take 35 parts of mung bean starch and 20 parts of sodium hydroxide, add 170 parts of ethanol solution with a volume ratio of 95%, and place in a constant temperature water bath at 45 °C Stir in the pot at 350r / min for 50min; then add 12 parts of chloroacetic acid, adjust the pH to 7 with 1mol / L hydrochloric acid solution; place it in a constant temperature water bath at 45°C and stir at 350r / min for 1.5h, filter, After washing with an ethanol solution with a volume ratio of 95%, put it into an oven at 55° C. to dry to obtain carboxymethylated mung bean starch, which is set aside;

[0020] (2) Preparation of composite gel solution: Take 30 parts of konjac glucomannan and 11 parts of carboxymethylated mung bean starch obtained in step (1), add 700 parts of water, place...

Embodiment 2

[0023] Embodiment 2, a kind of preparation method of konjac glucomannan toilet seat, comprises the following steps:

[0024] (1) Preparation of carboxymethylated mung bean starch: according to the mass components, take 30 parts of mung bean starch and 15 parts of sodium hydroxide, add 140 parts of ethanol solution with a volume ratio of 95%, and place in a constant temperature water bath at 40 °C Stir in the pot at 300r / min for 45min; then add 10 parts of chloroacetic acid, adjust the pH to 6.5 with 1mol / L hydrochloric acid solution; place it in a constant temperature water bath at 40°C and stir at 300r / min for 1h, filter, and use After being washed with an ethanol solution with a volume ratio of 95%, put it into an oven at 50° C. to dry to obtain carboxymethylated mung bean starch for subsequent use;

[0025] (2) Preparation of composite gel solution: take 25 parts of konjac glucomannan and 10 parts of carboxymethylated mung bean starch obtained in step (1), add 600 parts of ...

Embodiment 3

[0028] Embodiment 3, a kind of preparation method of konjac glucomannan toilet seat, comprises the following steps:

[0029] (1) Preparation of carboxymethylated mung bean starch: according to the mass components, take 40 parts of mung bean starch and 25 parts of sodium hydroxide, add 200 parts of ethanol solution with a volume ratio of 95%, and place in a constant temperature water bath at 50 °C Stir in the pot at 400r / min for 55min; then add 14 parts of chloroacetic acid, adjust the pH to 7.5 with 1mol / L hydrochloric acid solution; place it in a constant temperature water bath at 50°C and stir at 350r / min for 1.5h, filter, After washing with an ethanol solution with a volume ratio of 95%, put it into an oven at 60° C. to dry to obtain carboxymethylated mung bean starch, which is set aside;

[0030] (2) Preparation of composite gel solution: Take 35 parts of konjac glucomannan and 12 parts of carboxymethylated mung bean starch obtained in step (1), add 800 parts of water, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com