Crosslinked polyethylene electric-insulation material and preparation method thereof

A technology of cross-linked polyethylene and insulating materials, which is applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of low breakdown voltage and easy aging, so as to reduce the working temperature, prolong the service life and eliminate space The effect of charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

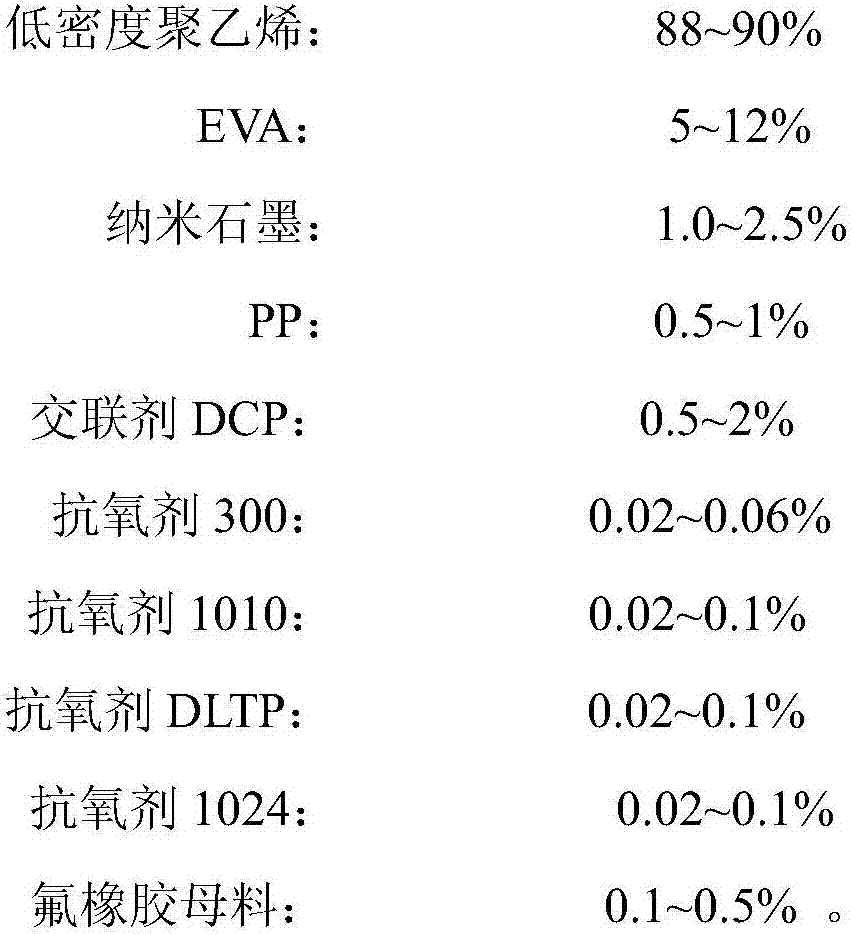

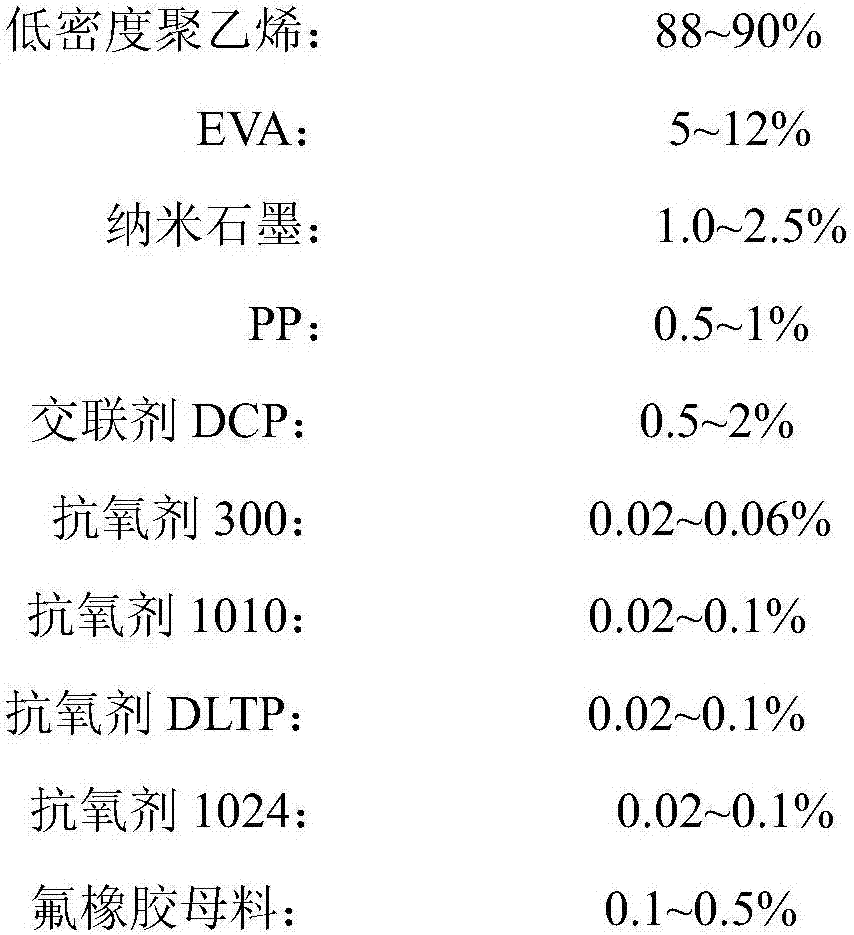

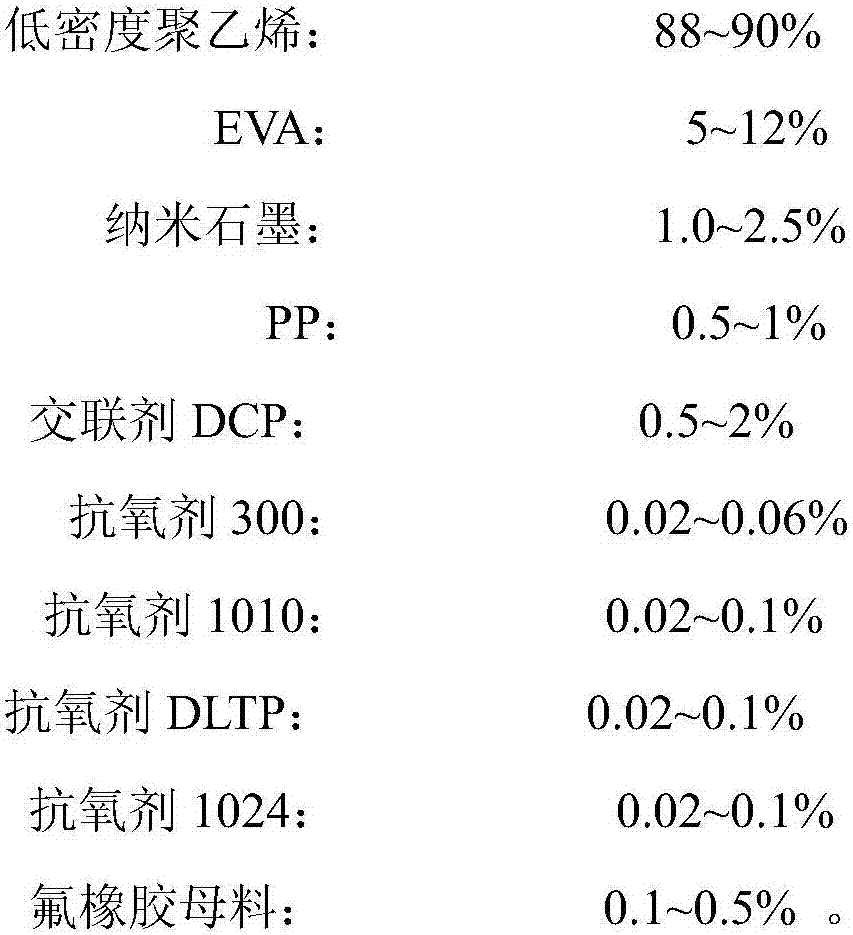

[0015] Embodiment 1: The cross-linked polyethylene insulating material of this embodiment is prepared from the following components in terms of mass percentage:

[0016]

specific Embodiment approach 2

[0017] Specific implementation mode two: the preparation method of the cross-linked polyethylene insulating material of the present implementation mode, the specific steps are:

[0018] Step 1. Take 100 parts of XLPE, EVA, nano-graphite, PP, crosslinking agent DCP, antioxidant 300, antioxidant 1010, antioxidant DLTP, antioxidant 1024, and fluororubber masterbatch according to the proportion;

[0019] Step 2. Add XLPE, EVA, nano-graphite, PP, crosslinking agent DCP, antioxidant 300, antioxidant 1010, antioxidant DLTP, antioxidant 1024, and fluororubber masterbatch to the mixer and mix evenly;

[0020] Step 3, transfer the above materials into a closed mixer, and carry out melt blending at a temperature of 100-120°C;

[0021] Step 4, transfer the above materials into a flat vulcanizer, carry out a cross-linking reaction at 150-180° C., and obtain a cross-linked polyethylene product added with nano-graphite after 30-60 minutes;

[0022] Step 5. After cooling the product obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com