A method for enriching and purifying indium from acid leaching solution containing ito waste by salting out

A technology of waste acid and action, applied in the field of recycling and utilization of waste containing ITO, to achieve the effect of efficient separation, high purity, and efficient enrichment and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

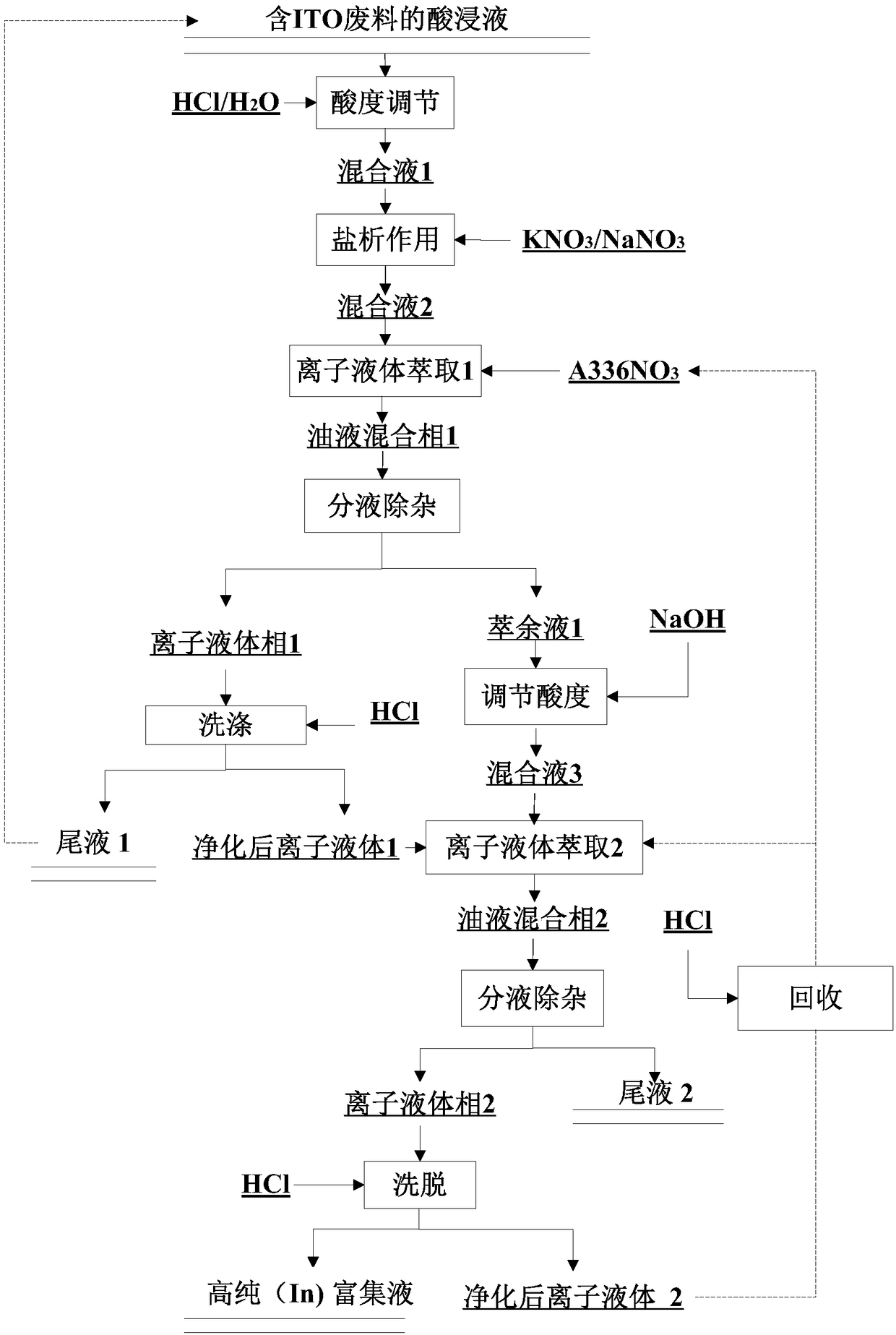

Method used

Image

Examples

Embodiment 1

[0023] Adjust the acid dipping solution hydrochloric acid concentration containing ITO waste to 4mol / L to obtain mixed solution 1; add salting-out agent sodium nitrate in mixed solution 1 to obtain mixed solution 2, and the corresponding sodium nitrate concentration is 3mol / L; mixed solution 2 Add ionic liquid A336NO 3 As an extractant, the corresponding oil-to-liquid volume ratio is 1:20, and the oil-liquid mixed phase 1 is obtained after extraction for 20 minutes; the oil-liquid mixed phase 1 is separated to obtain Fe-containing 3+ , Sn 2+ The ionic liquid phase 1 and containing In 3+ 、Al 3+ , Ca 2+ 、Na + , Mg 2+ The raffinate 1; the ionic liquid phase 1 is washed and purified with 0.5mol / L hydrochloric acid washing solution with an oil / liquid ratio of 1:5 for 30 minutes, and the purified ionic liquid 1 can be recycled; the raffinate 1 utilizes hydrogen The sodium oxide solution adjusts the acidity to 0.2mol / L to obtain a mixed solution 3; add 1 / 2 of the purified ionic...

Embodiment 2

[0025] Adjust the acid dipping solution hydrochloric acid concentration containing ITO waste to 5mol / L to obtain mixed solution 1; the salting-out agent sodium nitrate in mixed solution 1 obtains mixed solution 2, and the corresponding sodium nitrate concentration is 2.5mol / L; mixed solution 2 Add ionic liquid A336NO 3 As an extractant, the corresponding volume ratio of oil to liquid is 1:1. After 40 minutes of extraction, the oil-liquid mixed phase 1 is obtained; the oil-liquid mixed phase 1 is separated to obtain Fe-containing 3+ , Sn 2+ The ionic liquid phase 1 and containing In 3+ 、Al 3+ , Ca 2+ 、Na + , Mg 2+ The raffinate 1; the ionic liquid phase 1 is washed and purified with 0.8mol / L hydrochloric acid washing solution with an oil / liquid ratio of 1:8 for 20 minutes, and the purified ionic liquid 1 can be recycled; the raffinate 1 is oxidized by hydrogen The sodium solution adjusts the acidity to 0.4mol / L to obtain the mixed solution 3; the purified ionic liquid 1 / 2...

Embodiment 3

[0027] Adjust the concentration of hydrochloric acid in the pickling solution containing ITO waste to 5mol / L to obtain a mixed solution 1; in the mixed solution 1, the salting-out agent sodium nitrate is obtained to obtain a mixed solution 2, and the corresponding concentration of sodium nitrate is 2mol / L; in the mixed solution 2, add Ionic liquid A336NO 3 As an extractant, the corresponding oil-to-liquid volume ratio is 1:20, and the oil-liquid mixed phase 1 is obtained after extraction for 10 minutes; the oil-liquid mixed phase 1 is separated to obtain Fe-containing 3+ , Sn 2+ The ionic liquid phase 1 and containing In3+ 、Al 3+ , Ca 2+ 、Na + , Mg 2+ raffinate 1; ionic liquid phase 10.2mol / L hydrochloric acid with an oil / liquid ratio of 1:15, after washing and purifying for 10 minutes, the purified ionic liquid 1 can be recycled; raffinate 1 is adjusted by sodium hydroxide solution The acidity reaches 0.1mol / L to obtain the mixed liquid 3; the purified ionic liquid 1 / 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com