Smoke dedusting silencer

A muffler and flue gas technology, applied in the direction of sound absorption, exhaust devices, exhaust treatment, etc., can solve the problems of no comprehensive treatment of dust removal and noise reduction, affecting people's physical and mental health, polluting the environment, etc., to achieve good practicability and reduce emissions , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

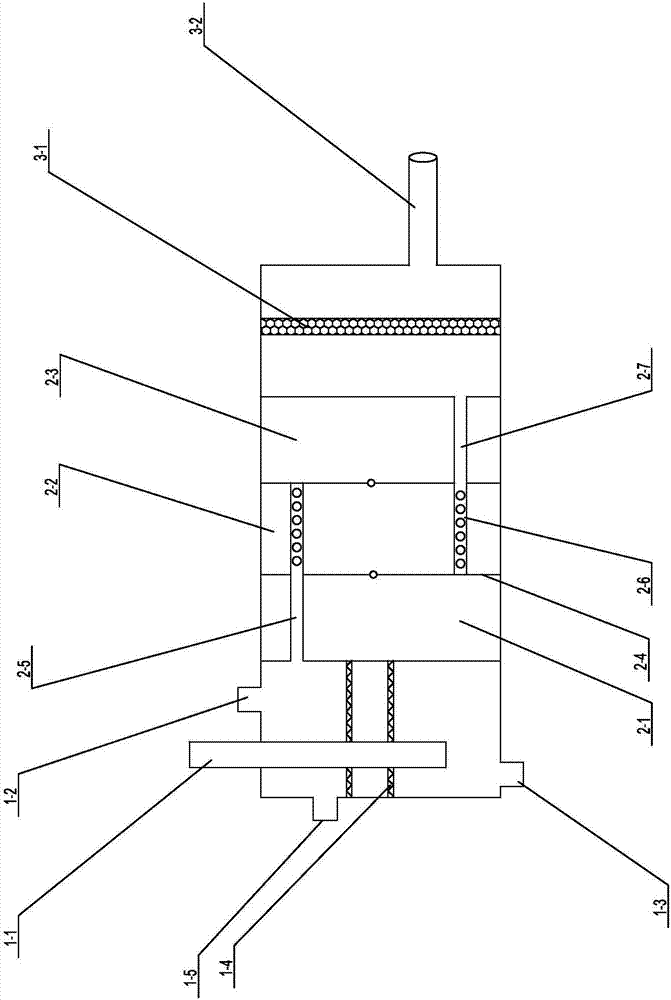

[0016] Such as figure 1 and figure 2 As shown, a specific embodiment of the present invention is proposed. The flue gas dedusting muffler includes a cylindrical device body. The upper end of the dust removal chamber 1 is provided with an air intake pipe 1-1 and a water inlet 1-2, and the lower end is provided with a sewage outlet 1-3, and several layers of dust removal nets 1-4 are arranged in the primary dust removal chamber 1, and the inlet The air pipe 1-1 runs through all the dust removal nets 1-4. The more layers of the dust removal nets 1-4 are set, the better the dust removal effect. In this embodiment, two layers of dust removal nets 1-4 are set in combination with the production cost and manufacturing process. For example, a water outlet 1-5 is provided on the primary dust removal chamber 1 and above the first layer of dust removal net 1-4. The water outlet 1-5 is mainly used to prompt to stop adding water. After the net 1-4, water will flow out from the water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com