Methylation treatment gas phase detection and analysis method

A technology of gas phase detection and analysis method, which is applied in the direction of analyzing materials, measuring devices, and material separation. It can solve problems such as long-term preservation, difficult control of ultrasonic conditions, and high toxicity. It achieves simple operation, fast derivation speed, and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

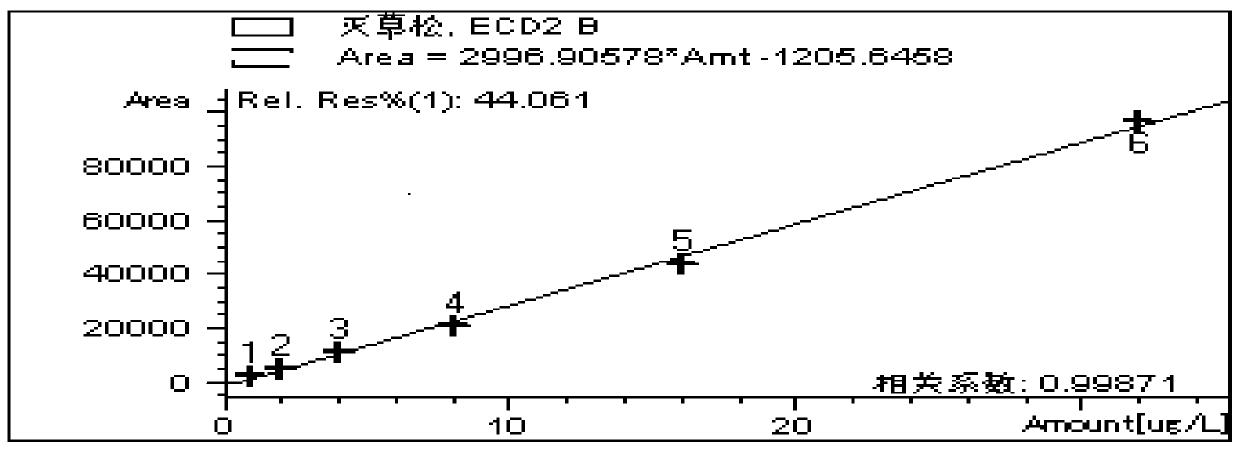

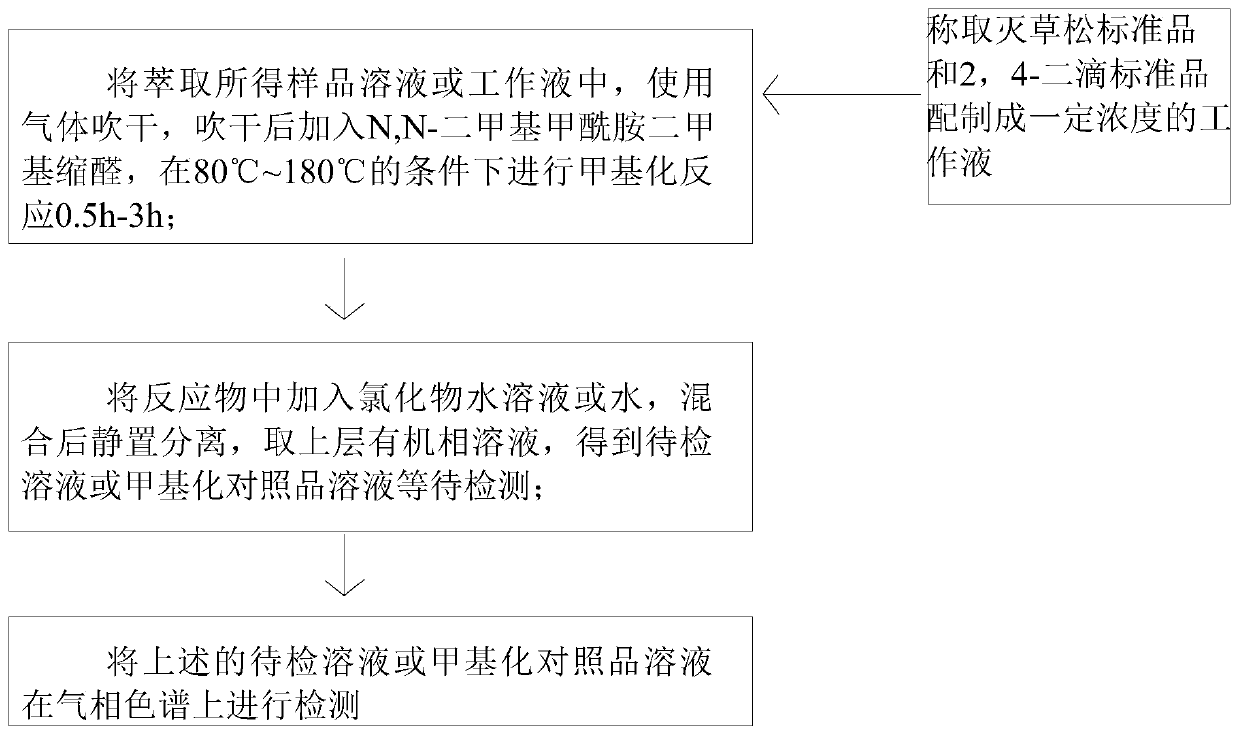

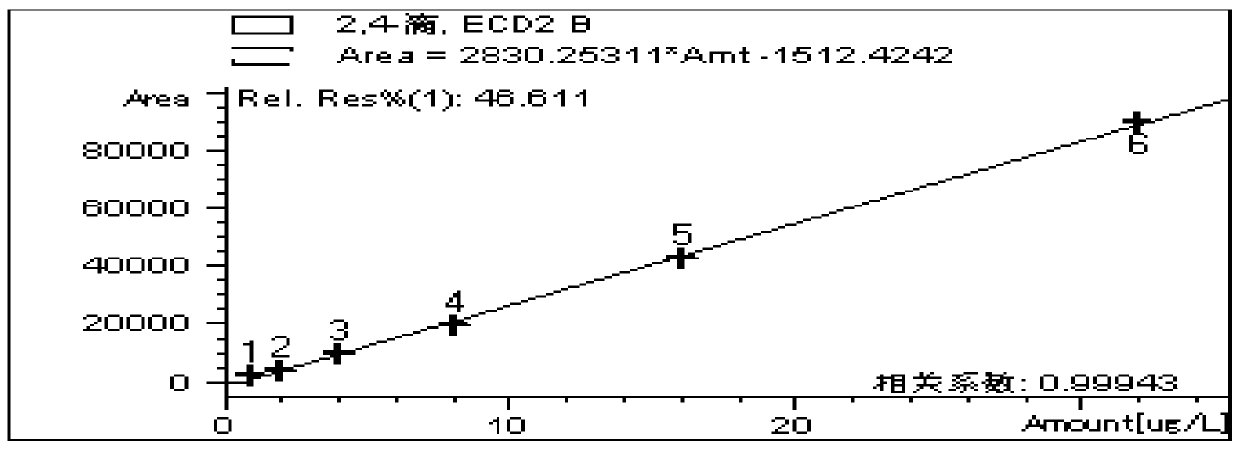

[0057] Embodiment 1: The present invention discloses a gas-phase detection and analysis method for methylation treatment,

[0058] 1) Water sample pretreatment: first measure 200mL of water sample and place it in a 500mL separating funnel, add 50mL of ethyl acetate to extract the water sample for a total of three times, a total of 150mL was combined in a 200mL beaker, and nitrogen was blown in a water bath at 45°C. When there is 4-5 mL of ethyl acetate left, transfer it to the derivation tube, rinse the beaker with 2 mL of ethyl acetate, combine them into the derivation tube, and continue drying in a water bath with nitrogen.

[0059] 2) Methylation reaction: Take the sample solution in the organic phase (that is, obtained by extraction) and transfer it to the derivatization test tube, blow dry with nitrogen, and add 200 μL of N,N-dimethylformamide dimethyl acetal after drying and 1.0 mL of isooctane, capped and sealed, vortexed for 1 min, and placed in an oven at 80°C for met...

Embodiment 2

[0065] 1) Water sample pretreatment: first measure 200mL of water sample and place it in a 500mL separating funnel, add 50mL of ethyl acetate to extract the water sample for a total of three times, a total of 150mL was combined in a 200mL beaker, and nitrogen was blown in a water bath at 45°C. When there is 4-5 mL of ethyl acetate left, transfer it to the derivation tube, rinse the beaker with 2 mL of ethyl acetate, combine them into the derivation tube, and continue drying in a water bath with nitrogen.

[0066] 2) Methylation reaction: take the sample solution in the organic phase and transfer it into a container, blow dry with nitrogen gas, and add 500 μL of N,N-dimethylformamide dimethylformamide after drying Base acetal and 1.0mL isooctane, cover and seal, vortex for 5min, put in an oven at 180°C for methylation reaction for 3h.

[0067] 3) Extraction of the solution to be tested: after completion, take it out to return to room temperature, add 1.5mL of saturated sodium c...

Embodiment 3

[0071] 1) Water sample pretreatment: first measure 200mL of water sample and place it in a 500mL separating funnel, add 50mL of ethyl acetate to extract the water sample for a total of three times, a total of 150mL was combined in a 200mL beaker, and nitrogen was blown in a water bath at 45°C. When there is 4-5 mL of ethyl acetate left, transfer it to the derivation tube, rinse the beaker with 2 mL of ethyl acetate, combine them into the derivation tube, and continue drying in a water bath with nitrogen.

[0072] 2) Methylation reaction: take the sample solution in the organic phase and transfer it into a container, blow dry with nitrogen, add 400 μL of N,N-dimethylformamide dimethyl Base acetal and 1.0mL isooctane, cover and seal, vortex for 5min, put into an oven at 160°C for methylation reaction for 1h.

[0073] 3) Extraction of the solution to be tested: after completion, take it out to return to room temperature, add 1.5mL of saturated sodium chloride aqueous solution, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com