Application of a janus nanoparticle as an adhesive for filling materials in dental restorations

A nanoparticle and filling material technology, applied in dentistry, dental preparations, dental prostheses, etc., can solve the problems of insufficient bonding strength, strong hydrophilicity of HEMA, cytotoxicity, etc., and achieve a simple and easy preparation method and improve durability. performance, performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

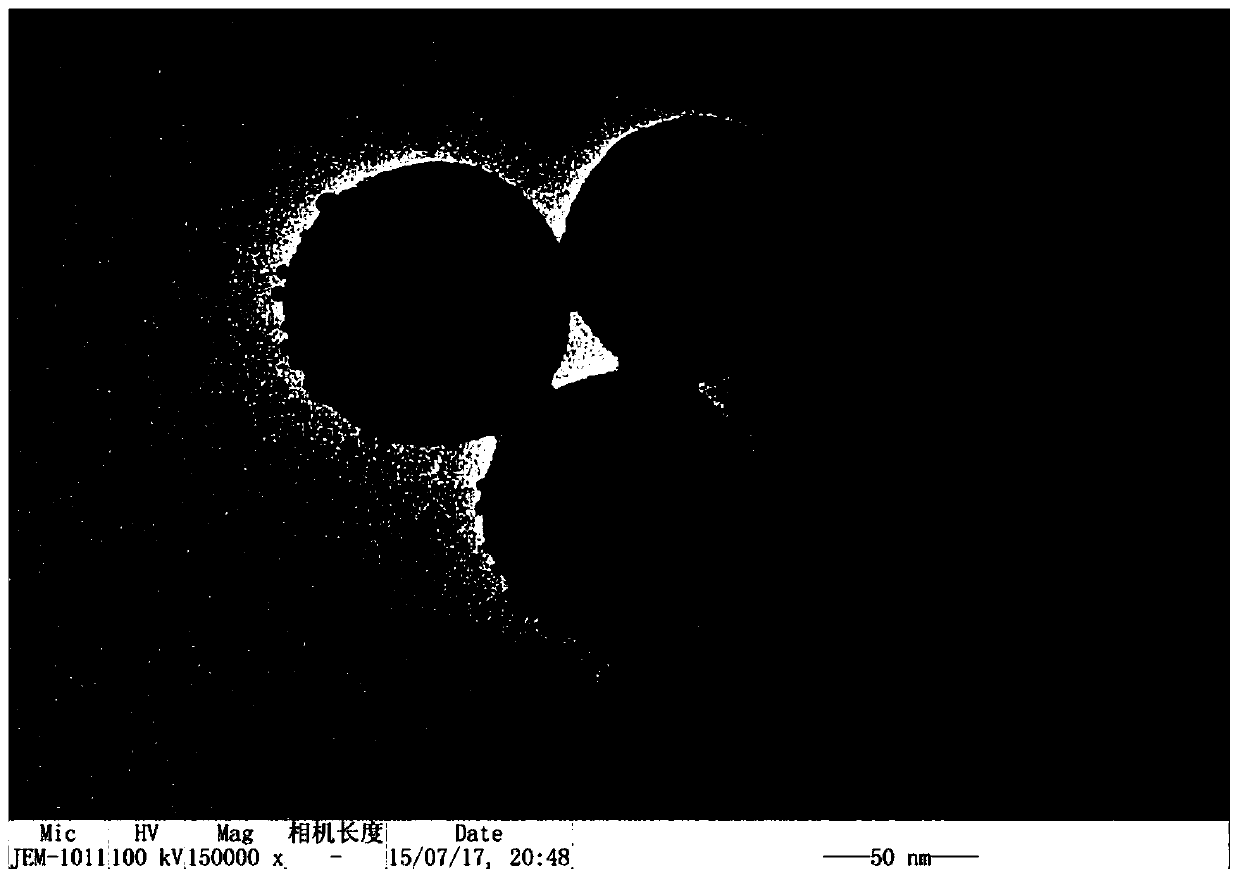

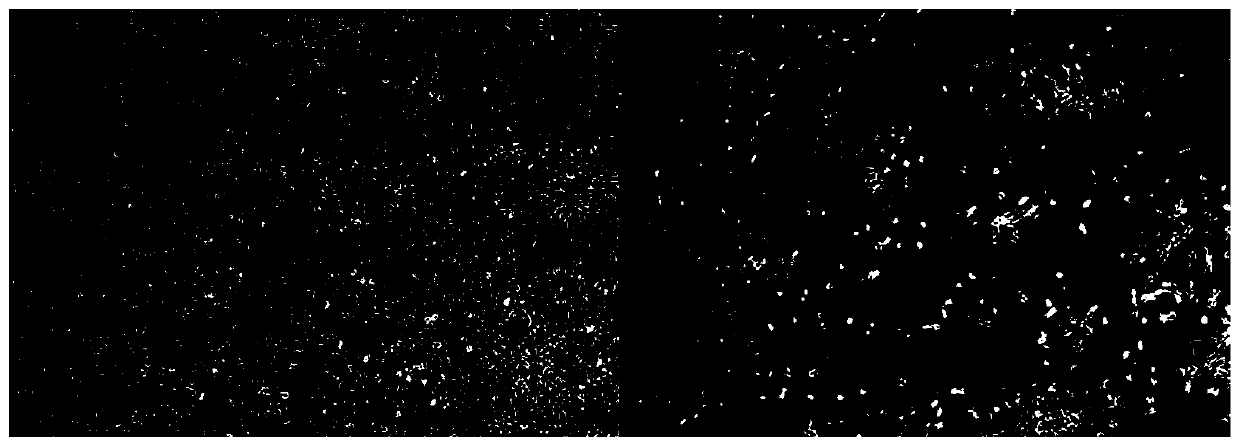

[0030] Janus nanoparticles, the main body is silica, with amino groups on one side of the hemisphere and carbon-carbon double bonds on the other side; the size is about 100nm, and it is uniform spherical, such as figure 1 shown; white powder; non-toxic, such as figure 2 shown; it can stabilize the water / oil two phases in the adhesive without phase separation, such as image 3 shown.

[0031] Preparation of Janus nanoparticles, the specific steps are as follows:

[0032] 1) preparing biologically inert silica nanoparticles with a diameter of about 100 nm;

[0033] 2) Prepare surface amino-modified silica nanoparticles, use APTMS to modify, and modify at a temperature of 76°C;

[0034] 3) using the Pickering emulsion method to perform selective modification and selective chemical modification on the surface to prepare Janus nanoparticles;

[0035] The surface amino-modified silica nanoparticles obtained in step 2 are dispersed in the mixed system of water and paraffin; the ...

Embodiment 2

[0041] Janus nanoparticles, the main body is silicon dioxide, with amino groups on one side of the hemisphere, and carbon-carbon double bonds on the other side; white powder; non-toxic; the size is about 50nm, in a uniform spherical shape;

[0042] Preparation of Janus nanoparticles, the specific steps are as follows:

[0043] 1) preparing biologically inert silica nanoparticles with a diameter of about 50 nm;

[0044] 2) Prepare surface amino-modified silica nanoparticles, use APTMS to modify, and modify at a temperature of 76°C;

[0045] 3) Use the Pickering emulsion method to carry out selective modification and selective chemical modification on the surface to prepare Janus nanoparticles; disperse the amino-modified silica nanoparticles obtained in step 2 in a mixed system of water and paraffin; The mass ratio of modified silica nanoparticles, water, and paraffin is 1:600:10), and the reaction temperature is 70°C; stirring for 15 minutes makes the nano-biological particle...

Embodiment 3

[0051] Janus nanoparticles, the main body is silicon dioxide, with amino groups on one side of the hemisphere, and carbon-carbon double bonds on the other side; white powder; non-toxic; the size is about 10nm, in a uniform spherical shape;

[0052] Preparation of Janus nanoparticles, the specific steps are as follows:

[0053] 1) preparing biologically inert silica nanoparticles with a diameter of about 10 nm;

[0054] 2) Prepare surface amino-modified silica nanoparticles, use APTMS to modify, and modify at a temperature of 76°C;

[0055] 3) Use the Pickering emulsion method to carry out selective modification and selective chemical modification on the surface to prepare Janus nanoparticles; disperse the amino-modified silica nanoparticles obtained in step 2 in a mixed system of water and paraffin; The mass ratio of modified silica nanoparticles, water, and paraffin is 1:300:20; stir for 15 minutes to distribute nano-biological particles in a single layer of paraffin / water i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com