Label scraping device for recycled glass bottle waste-label removal operation

A glass bottle and labeling technology, applied in the directions of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of poor reliability and versatility, stuck or broken recycled bottles, and limited force of the hob. , to achieve the effect of good reliability, ensuring stability and reliability, and smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

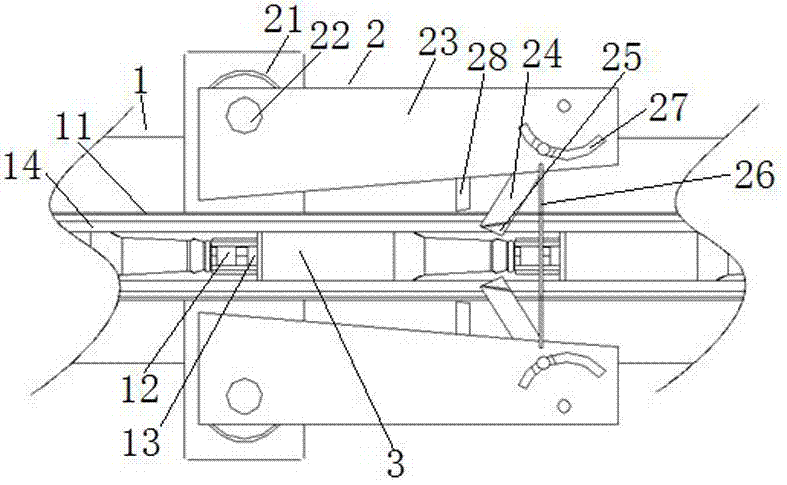

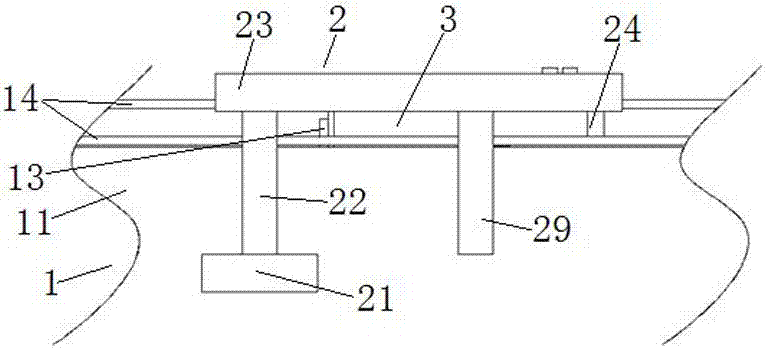

[0028] see figure 1 and figure 2 As shown, the reclaimed glass bottle 3 targeted by the present invention is circular, with a thin neck and a large structure, and the surface of the bottle body has an annular, heat-shrinkable polyvinyl chloride film label that is fixed and formed - that is, a waste label; The invention includes a conveying mechanism 1 and a marking mechanism 2 .

[0029]Wherein, the conveying mechanism 1 is a chain conveying mechanism, which is mainly composed of a frame 11 and a conveying chain plate 12 arranged on the frame 11, a transmission gear, a motor and a guardrail 14.

[0030] The frame 11 of the conveying mechanism 1 is a rectangular parallelepiped frame structure, and a plurality of groups of transmission gears are arranged at intervals in the length direction of the upper part of the frame 11. These transmission gears are divided into driving gears and driven gears according to the transmission sequence when doing work. The gear is connected wi...

Embodiment 2

[0039] The reclaimed glass bottle targeted by the present invention is circular, with a thin neck and a large belly, and the surface of the bottle body has a circular polyvinyl chloride film label fixed and formed by heat shrinkage—that is, a waste label; the present invention includes a conveying mechanism and marking agencies.

[0040] Wherein, the conveying mechanism is a chain conveying mechanism, which is mainly composed of a frame and a conveying chain plate arranged on the frame, a transmission gear, a motor and a guardrail.

[0041] The frame of the conveying mechanism is a rectangular parallelepiped frame structure. There are several sets of transmission gears arranged at intervals in the length direction of the upper part of the frame. These transmission gears are divided into driving gears and driven gears according to the transmission sequence when doing work. The mechanism is connected with the output shaft of the motor on the frame, and the driving gear drives th...

Embodiment 3

[0047] The recycled glass bottle targeted by the present invention has a square structure with a narrow neck and a large belly, and the surface of the bottle body has a circular, non-adhesive fixed-formed paper label—that is, a waste label; the present invention includes a conveying mechanism and marking mechanism.

[0048] Wherein, the conveying mechanism is a chain conveying mechanism, which is mainly composed of a frame and a conveying chain plate arranged on the frame, a transmission gear, a motor and a guardrail.

[0049] The frame of the conveying mechanism is a rectangular parallelepiped frame structure. There are several sets of transmission gears arranged at intervals in the length direction of the upper part of the frame. These transmission gears are divided into driving gears and driven gears according to the transmission sequence when doing work. The mechanism is connected with the output shaft of the motor on the frame, and the driving gear drives the action of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap