Flexible semiconductive shielding material and preparation method thereof

A semi-conductive, shielding material technology, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve the problems of hardening, embrittlement, processing performance and degradation of semi-conductive shielding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

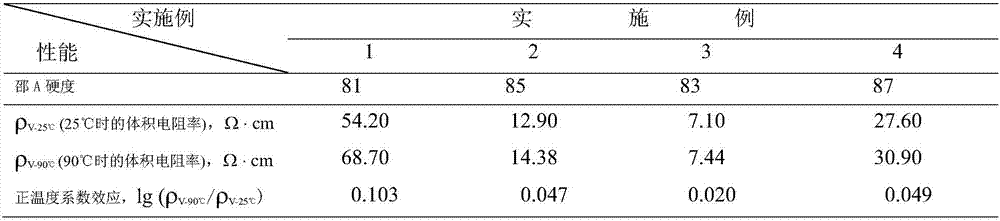

Examples

Embodiment 1

[0014] Embodiment 1: Preparation of flexible semiconductive shielding material

[0015] (1) 70.0 grams of EVA particles were first added to the torque rheometer at 115 ° C, the rotating speed was 65 rpm, then 30.0 grams of high-conductivity carbon black and 0.5 grams of antioxidant 1010 were added, and melt blended for 6 minutes;

[0016] (2) 30.0 grams of SEBS were added to the mixture of (1), melt blended for 3 minutes;

[0017] (3) Add 1.0 gram of crosslinking agent DCP, 1.5 gram of crosslinking aid TAIC and 1.0 gram of solid paraffin into the mixture of (2), melt and blend for 3 minutes, quickly take out the material from the mixer and cool to room temperature;

[0018] (4) Put the sample into a stainless steel mold with a polytetrafluoroethylene isolation film, preheat it at 160°C for 1 minute with a flat vulcanizer, mold it under a pressure of 10 MPa for 8 minutes, and then cool it on a flat vulcanizer at room temperature Press and shape to obtain a sheet sample for tes...

Embodiment 2

[0022] Embodiment 2: Preparation of flexible semiconductive shielding material

[0023] 70.0 grams of EVA; 35.0 grams of highly conductive carbon black; 1.0 grams of antioxidant 1010; 20.0 grams of SBS thermoplastic elastomer; 1.5 grams of crosslinking agent DCP, 2.5 grams of crosslinking auxiliary agent TAIC and 1.5 grams of paraffin wax. The rest is the same as implementation 1.

Embodiment 3

[0024] Embodiment 3: Preparation of flexible semiconductive shielding material

[0025] 80.0 grams of EVA; 40.0 grams of highly conductive carbon black; 1.5 grams of antioxidant 1010; 25.0 grams of SEBS thermoplastic elastomer; 2.0 grams of crosslinking agent DCP, 3.0 grams of crosslinking auxiliary agent TAIC and 2.5 grams of solid paraffin. The rest is the same as implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com