Frequency selective surface structure with improved angle stability

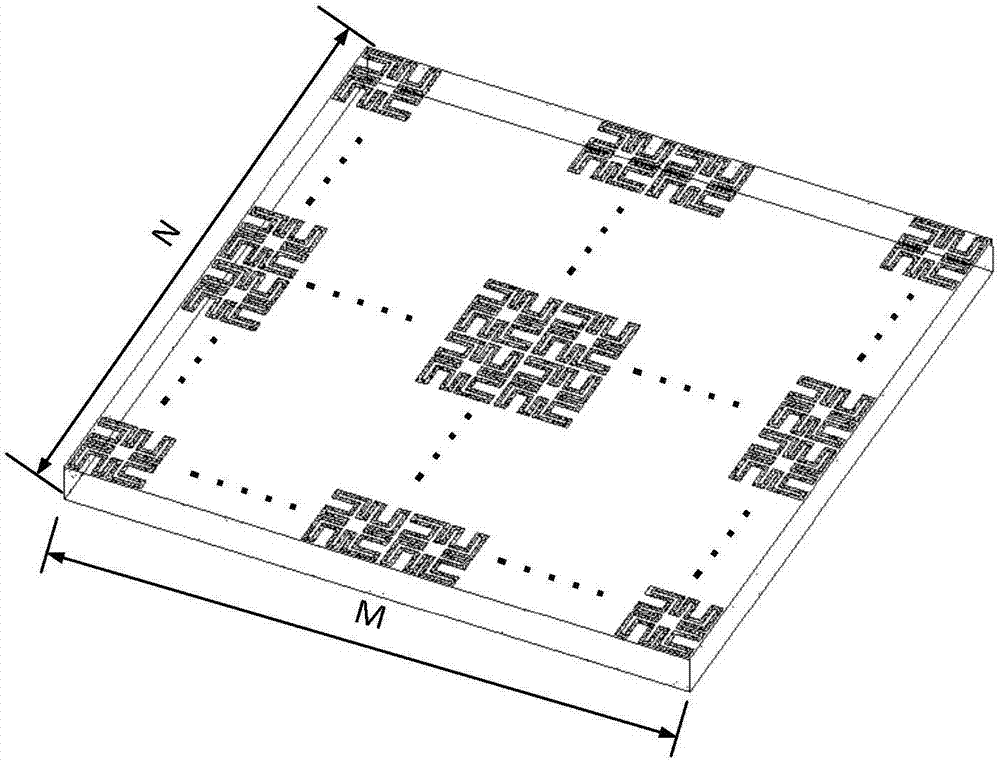

A frequency selective surface, stability technology, applied in electrical components, circuits, antennas, etc., can solve the problem of not meeting the needs of resonant frequency stability, achieve good resonant stability, reduce resonant frequency offset, and increase the current path. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1, a frequency selective surface unit with a dielectric substrate having a relative permittivity of 2.2, a patch length of 7.5 mm, and a zigzag strip width of 0.4 mm.

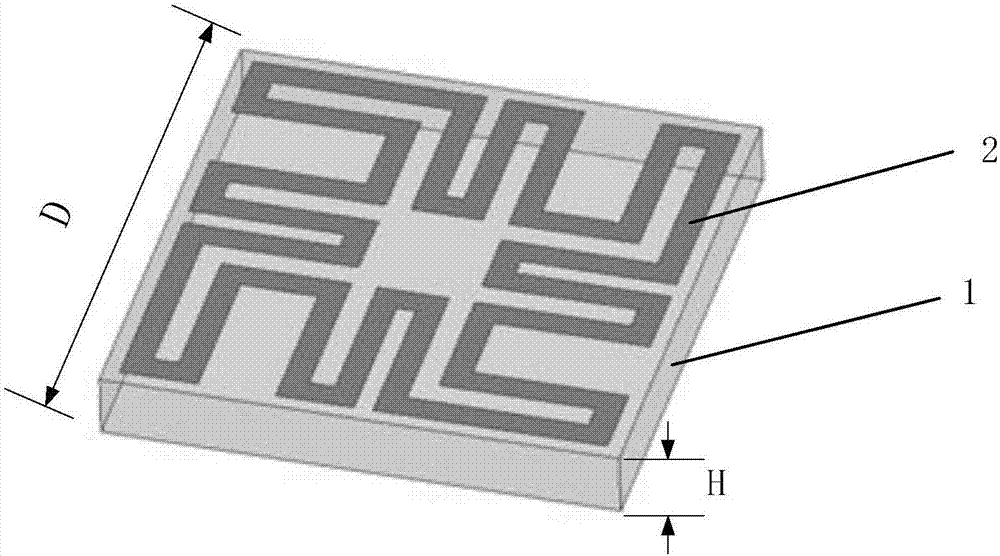

[0026] refer to figure 2 Each frequency selective surface unit in this example includes a dielectric substrate 1 and a metal patch 2 printed on its surface, and the metal patch 2 coincides with the geometric center of the upper surface of the dielectric substrate 1 . The dielectric substrate 1 adopts a square plate, and the use of the square plate ensures the polarization stability of the formed frequency selective surface structure; the side length of the dielectric substrate 1 is D=8mm, the thickness H=1mm, and the relative permittivity is 2.2.

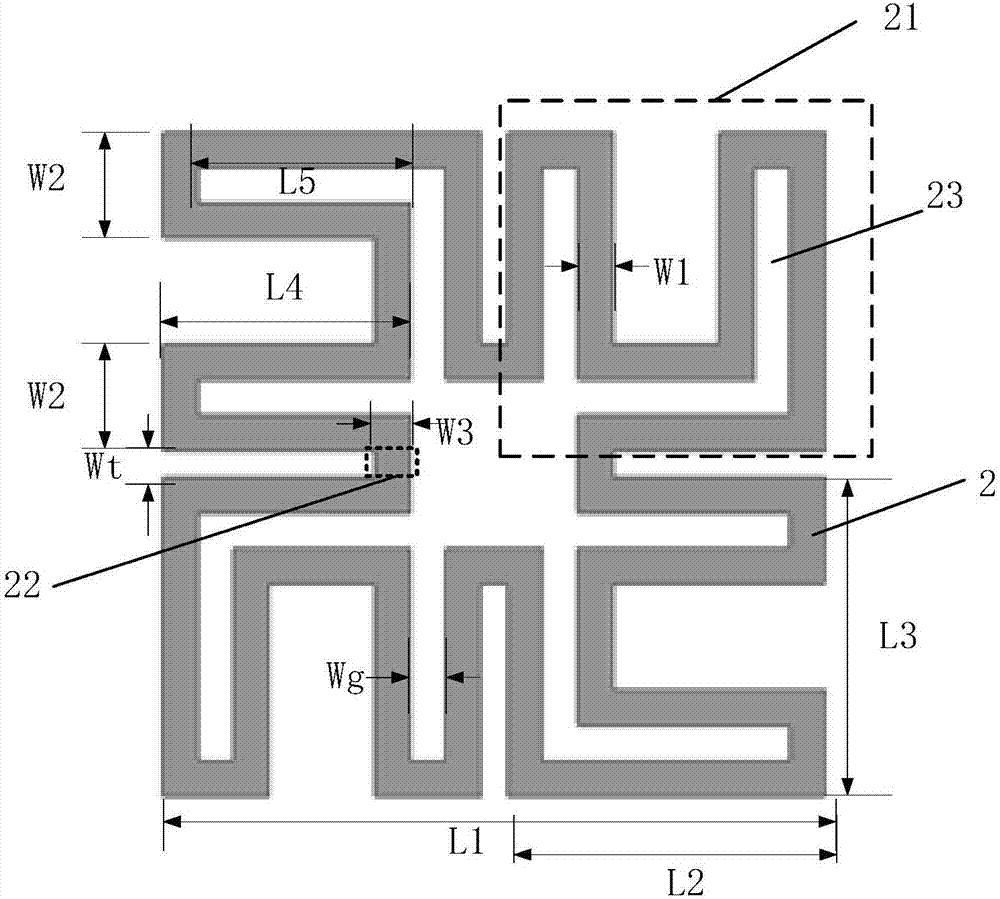

[0027] refer to image 3 , the length and width of the metal patch 2 of each frequency selective surface unit are equal, and smaller than the side length of the dielectric substrate. In this example, the length and width of the metal patch 2 are both...

Embodiment 2

[0028] Embodiment 2, a frequency selective surface unit with a dielectric substrate having a relative permittivity of 2.25, a patch length of 8.5 mm, and a meander strip width of 0.3 mm.

[0029] The structure of this embodiment is the same as that of Embodiment 1, and only the following parameters are adjusted:

[0030] The side length of the dielectric substrate 1 is D=9mm, the thickness is H=1.5mm, and the relative dielectric constant is 2.25. The length and width of the metal patch 2 are equal, and both are L1=8.5mm; each "concave" figure 21 The length L2 and the width L3 are equal, both are 4.0mm, the width W2 of the two outer vertical arms of each "concave" figure is 1.4mm, and the length L4 is 3.0mm; the length L5 of the hollow gap 23 is 2.6mm, and the width Wg is 0.8mm; the length Wt of the rectangular strip 22 is 0.5mm, and the width W3 of the rectangular strip 22 is equal to the width W1 of the meandering strip, which is 0.3mm.

Embodiment 3

[0031] Embodiment 3, a frequency selective surface unit with a dielectric substrate having a relative permittivity of 2.65, a patch length of 9 mm, and a meander strip width of 0.5 mm.

[0032] The present embodiment has the same structure as Embodiment 1, and its parameters are as follows:

[0033] The side length of the dielectric substrate 1 is D=9.5mm, the thickness is H=2mm, the relative permittivity is 2.65, the length and width of the metal patch 2 are equal, both are L1=9mm; each "concave" figure 21 The length L2 is equal to the width L3, which are both 4.1mm. The width W2 of the two outer vertical arms of each "concave" figure is 1.6mm, and the length L4 is 3.1mm; the length L5 of the hollow gap 23 is 2.8mm, and the width Wg is 1 mm; the length Wt of the rectangular strip 22 is 0.1 mm, and the width W3 of the rectangular strip 22 is equal to the width W1 of the meandering strip, which is 0.5 mm.

[0034] Effect of the present invention can be further illustrated by f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com