Beef pretreatment method

A pretreatment and beef technology, applied in the direction of preservation of meat/fish with chemicals, preservation of meat/fish by freezing/cooling, food ingredients as taste improvers, etc., can solve the problems of short storage period, protein loss, deterioration, etc. Achieve the effects of round and mellow taste, extended shelf life and ideal gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

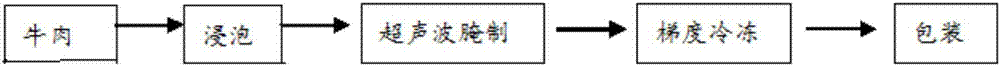

[0026] A kind of beef preprocessing method, comprises the following steps:

[0027] (1) Soak

[0028] Take fresh beef, cut into pieces, soak in 0.1% citric acid water for 20-30 minutes, remove the blood, soak in 0.1% sodium bicarbonate aqueous solution for 20-30 minutes, remove the blood and impurities again, and drain;

[0029] (2) Ultrasonic treatment

[0030] Prepare the pickling liquid according to the following proportions: 100 parts of beef, 5 parts of lactic acid, 12 parts of citric acid, 0.2 parts of sodium bicarbonate, 0.5 parts of papain, 0.5 parts of ficin, 0.2 parts of transglutaminase, 1 part of potato starch, 10 parts of water, ultrasonic treatment is carried out during pickling, the ultrasonic parameters are as follows: 300W, 120kHz, ultrasonic time is 20 minutes;

[0031] (3) Gradient freezing

[0032] The beef after ultrasonic treatment was frozen at 0°C to 4°C for 30 minutes, -15°C to -20°C for 25 minutes, and -45°C to -55°C for 25 minutes;

[0033] (4) P...

Embodiment 2

[0036] A kind of beef preprocessing method, comprises the following steps:

[0037] (1) Soak

[0038] Take fresh beef, cut into pieces, soak in 0.1% citric acid water for 20-30 minutes, remove the blood, soak in 0.1% sodium bicarbonate aqueous solution for 20-30 minutes, remove the blood and impurities again, and drain;

[0039] (2) Ultrasonic treatment

[0040] Prepare the pickling liquid according to the following proportions: 100 parts of beef, 5 parts of lactic acid, 12 parts of citric acid, 0.2 parts of sodium bicarbonate, 0.5 parts of papain, 0.5 parts of ficin, 0.2 parts of transglutaminase, 1 part of potato starch, 10 parts of water, ultrasonic treatment is carried out during pickling, the ultrasonic parameters are as follows: 300W, 120kHz, ultrasonic time is 25 minutes;

[0041] (3) Gradient freezing

[0042] The beef after ultrasonic treatment was frozen at 0°C to 4°C for 30 minutes, -15°C to -20°C for 25 minutes, and -45°C to -55°C for 25 minutes;

[0043] (4) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com