Black TiO2 nano material as well as preparation method and application thereof

A nano-material and black technology, applied in chemical instruments and methods, titanium oxide/hydroxide, light water/sewage treatment, etc., can solve the problems of high energy consumption and high risk of operation process, and achieve simple operation and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

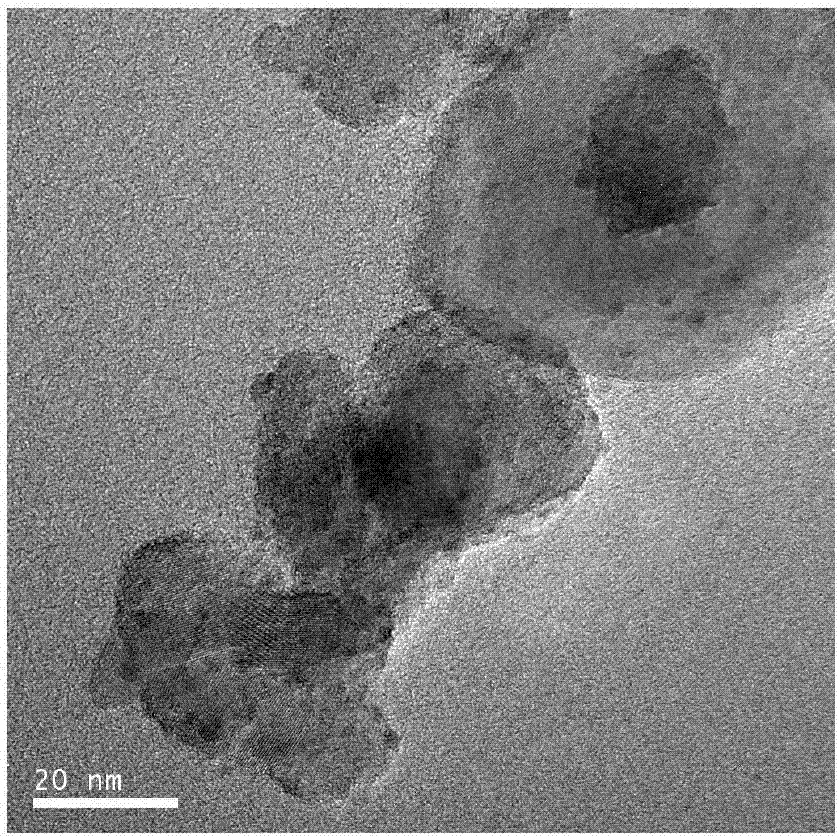

Image

Examples

Embodiment 1

[0025] First, weigh 2g of dried Arborvitae leaf powder, add 200mL of deionized water, place it in a constant temperature oil bath at 30°C, mix and stir for 2 hours, and then filter to obtain the filtrate. Take 30mL of the filtrate and 20mL of deionized water and add 1140μL, 48.56 MM silver nitrate aqueous solution was stirred at 90°C for 1.0h to obtain a mixed solution, and 0.6g TiO 2 The carrier was added to the obtained mixture (so that the Ag load was 1 wt%), stirred thoroughly for 1 hour, filtered, washed with water, and dried in vacuum. The obtained powder was treated in an air atmosphere at 450°C for 4 hours, and the plant biomass was removed to obtain a powder Catalyst A.

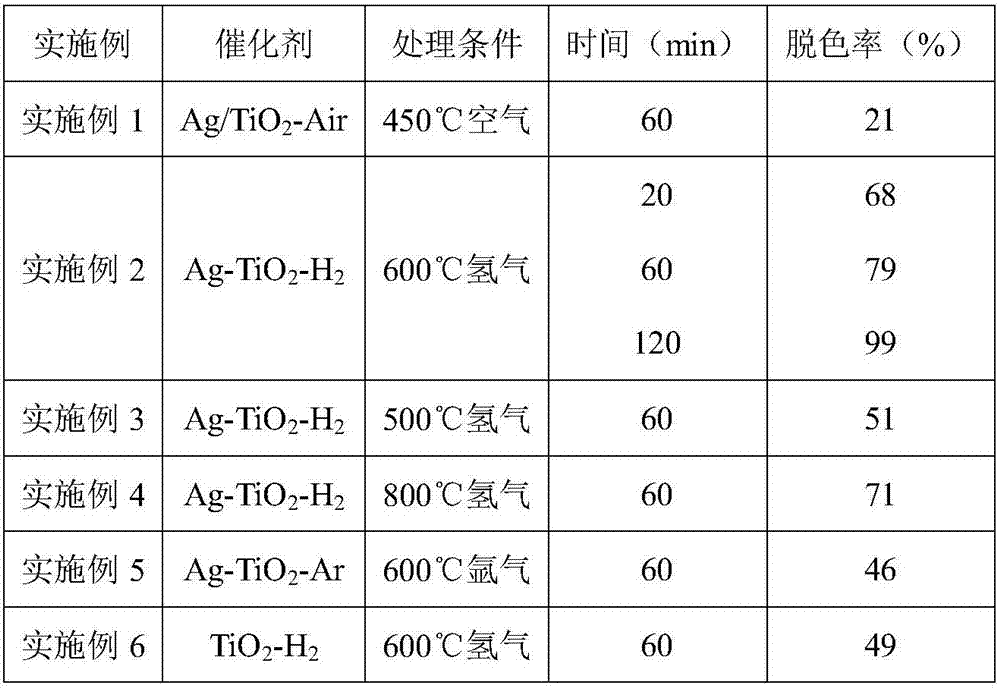

[0026] Photocatalytic degradation of methylene blue: prepare 20mg / L methylene blue solution for photocatalytic degradation reaction in the laboratory, take a certain amount (500mL) of the dye solution and pour it into the reaction kettle, take the initial sample, add the catalyst and absorb it in the...

Embodiment 2

[0028] Catalyst A was prepared according to the method of Example 1, and further treated at 600° C. for 4 hours under a 10% hydrogen / nitrogen mixed atmosphere to obtain catalyst B. Catalyst evaluation conditions are the same as in Example 1, and the catalytic reaction results are shown in Table 1.

Embodiment 3

[0030] Catalyst A was prepared according to the method of Example 1, and further treated at 500° C. for 4 hours under a 10% hydrogen / nitrogen mixed atmosphere to obtain catalyst C. Catalyst evaluation conditions are the same as in Example 1, and the catalytic reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com