Method for treating high-concentration organic arsenic wastewater and recycling arsenic

A technology for wastewater treatment and recovery methods, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as wastewater difficulties and arsenic secondary pollution, and achieve simple and easy control methods and operating costs. Low, avoid the effect of secondary pollution of arsenic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

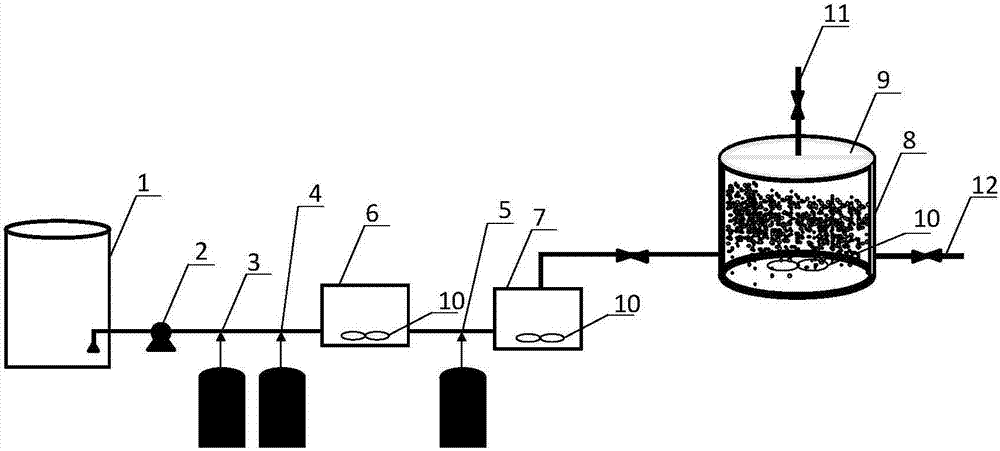

Image

Examples

Embodiment 1

[0037] The concentration of p-ASA in the water to be treated was 1 mmol / L. Adjust the pH value of the water to be treated to 3.5, and enter the second-stage oxidation reactor in turn under the action of the pump lift. In the first-stage oxidation reactor, add potassium permanganate solution under rapid stirring conditions, of which potassium permanganate The molar ratio with organic arsenic is 1:5, react for 0.5min; then enter the second-stage oxidation reactor, and add manganese chloride solution under rapid stirring conditions, wherein the molar ratio of manganese chloride to potassium permanganate is 1 : 5, continue to react for 30 minutes; the effluent enters the fully mixed flow reactor.

[0038]In the fully mixed flow reactor, under the condition of rapid stirring, nanometer iron hydroxide hydroxide adsorbent is added, the molar ratio of nanometer iron hydroxide hydroxide adsorbent to organic arsenic is 1:10, and the reaction takes 10 minutes to complete the adsorption o...

Embodiment 2

[0041] The concentration of p-ASA in the water to be treated is 10mmol / L. Adjust the pH value of the water to be treated to 4.0, and enter the second-stage oxidation reactor in turn under the action of the pump lift. In the first-stage oxidation reactor, add potassium permanganate solution under rapid stirring conditions, of which potassium permanganate The molar ratio with organic arsenic is 5:1, react for 5 minutes; then enter the second-stage oxidation reactor, and add manganese chloride solution under rapid stirring conditions, wherein the molar ratio of manganese chloride to potassium permanganate is 1: 100, continue to react for 120min; the effluent enters the fully mixed flow reactor.

[0042] In the fully mixed flow reactor, under the condition of rapid stirring, nanometer iron hydroxide hydroxide adsorbent is added, the molar ratio of nanometer iron hydroxide hydroxide adsorbent to organic arsenic is 10:1, and the reaction takes 60 minutes to complete the adsorption o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com