Method for preparing acetate porous starch through ultrasonic assistance

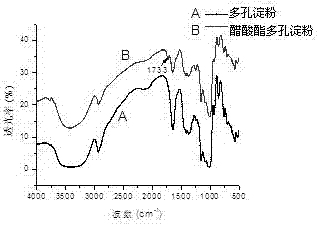

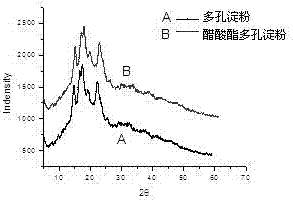

A technology of porous starch and acetate, applied in the field of starch modification, can solve problems such as difficult esterification, and achieve the effect of changing the adsorption properties, keeping the pores intact, and improving the degree of substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

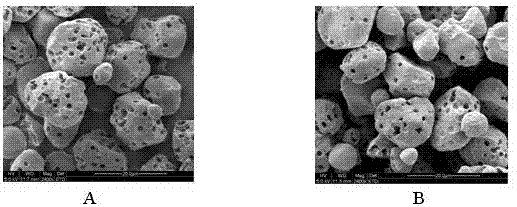

[0019] (1) Dissolve 30g of starch in 100mL of phosphate buffer solution with a pH of 4.5, place in a water bath and preheat at 40°C for 40min, then add α-amylase and glucoamylase (α-amylase and Glucoamylase volume ratio = 2:5), reacted for 10 hours under stirring conditions, neutralized with 3% sodium hydroxide solution, finally filtered, washed, dried and pulverized. The prepared porous starch was characterized by scanning electron microscopy.

[0020] (2) Weigh 30g of the porous starch prepared in step (1), dissolve it in 80mL of deionized water, and then add a mixed solution of acetic acid and acetic anhydride with 10% of the mass of the porous starch (the volume ratio of acetic acid and acetic anhydride is 1:3) , adjust the pH of the starch emulsion solution to 8.0 with 3% NaOH solution, then place the starch emulsion solution in an ultrasonic pulverizer, adjust the ultrasonic power to 200W, the time to 150min, and the temperature to 30°C, and finally neutralize it to pH6 ...

Embodiment 2

[0022] (1) Dissolve 30g of starch in 100mL of phosphate buffer solution with a pH of 4.5, place in a water bath and preheat at 40°C for 60min, then add α-amylase and glucoamylase (α-amylase and Glucoamylase volume ratio = 1:3), reacted for 12 hours under stirring conditions, neutralized with 3% sodium hydroxide solution, and finally filtered, washed, dried, and pulverized. The prepared porous starch was characterized by scanning electron microscopy.

[0023] (2) Weigh 30g of porous starch prepared in step (1), dissolve it in 100mL of deionized water, then add a mixed solution of acetic acid and acetic anhydride with 10% of the mass of porous starch (volume ratio of acetic acid and acetic anhydride = 2:5), Adjust the pH of the starch milk solution to 8.5 with a mass concentration of 3% NaOH solution, then place the starch milk solution in an ultrasonic pulverizer, adjust the ultrasonic power to 300W, the time to 120min, and the temperature to 30°C, and finally neutralize it wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap