Salt-tolerant nano-film oil displacement agent for oil field

A technology of nano-membrane and oil-displacing agent, which is applied in the field of oil-displacement. It can solve the problems of nano-membrane oil-displacing agent not being resistant to salt, changing the adsorption properties of reservoirs, and poor effect, and achieving strong resistance to mineral salts and low interfacial tension. , good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

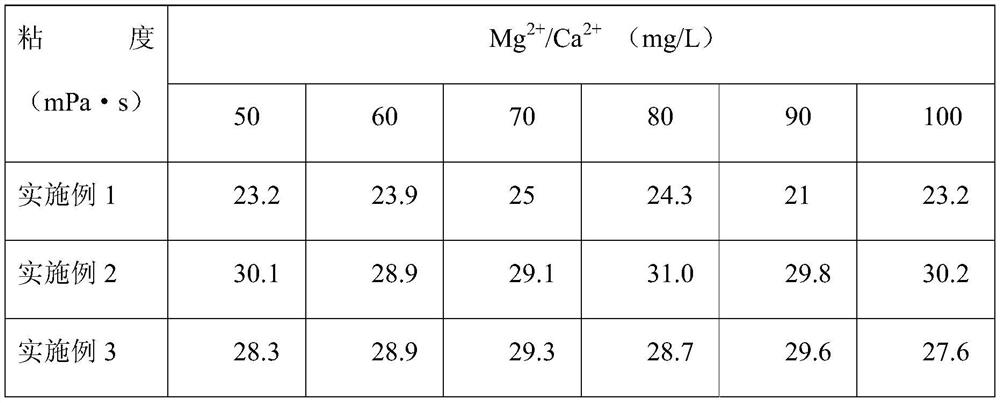

Embodiment 1

[0016] The salt-tolerant nano-membrane oil displacement agent for oil field of the present invention comprises nano-molecular deposition film agent, dimer sodium sulfonate gemini surfactant, the quality of nano-molecular deposition film agent and dimer sodium sulfonate gemini surfactant The ratio is 20:1.

[0017] The nano-molecular deposition film agent is prepared by the following method: take epichlorohydrin and ethylenediamine as raw materials, and carry out polymerization reaction under the action of initiator potassium sulfate, and the molar ratio of epichlorohydrin to ethylenediamine is 2:1 , the polymerization reaction temperature was 70°C, and the reaction time was 2h.

[0018] The salt-tolerant nano-membrane oil displacement agent for oil fields of the present invention is prepared by the following method: put the nano-molecular deposition film agent and the dimer sodium sulfonate gemini surfactant into the reaction kettle, heat up to 40°C and stir, and mix evenly H...

Embodiment 2

[0020] The salt-tolerant nano-membrane oil displacement agent for oil field of the present invention comprises nano-molecular deposition film agent, dimer sodium sulfonate gemini surfactant, the quality of nano-molecular deposition film agent and dimer sodium sulfonate gemini surfactant The ratio is 10:1.

[0021] The nanometer molecular deposition film agent is made by the following method: take epichlorohydrin and ethylenediamine as raw materials, and carry out polymerization reaction gained under the action of initiator sodium persulfate, and the mol ratio of epichlorohydrin and ethylenediamine is 1: 1. The polymerization reaction temperature is 60°C, and the reaction time is 3 hours.

[0022] The salt-tolerant nano-membrane oil displacement agent for oil fields of the present invention is prepared by the following method: put the nano-molecular deposition film agent and the dimer sodium sulfonate gemini surfactant into the reaction kettle, heat up to 40°C and stir, and mix...

Embodiment 3

[0024] Salt-tolerant nano-film oil displacement agent for oilfields of the present invention comprises nano-molecular deposition film agent, dimer sodium carboxylate gemini surfactant, the quality of nano-molecular deposition film agent and dimer sodium carboxylate gemini surfactant The ratio is 20:1.

[0025] The nano-molecular deposition film agent is prepared by the following method: using epichlorohydrin and dibutylamine as raw materials, it is obtained by polymerization reaction under the action of initiator sodium sulfate, and the molar ratio of epichlorohydrin to ethylenediamine is 3:1 , the polymerization reaction temperature was 80° C., and the reaction time was 1 h.

[0026] The salt-tolerant nano-membrane oil displacement agent for oil fields of the present invention is prepared by the following method: put the nano-molecular deposition film agent and the dimer sodium carboxylate gemini surfactant into the reaction kettle, heat up to 40°C and stir, and mix evenly H...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap