Pearlescent powder composite powder coating and preparation method thereof

A powder coating and pearlescent powder technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as environmental pollution, raw material performance impact, powder coating formula design, raw material matching and use, etc., to improve stability and electrification properties, promote electrification, and promote stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

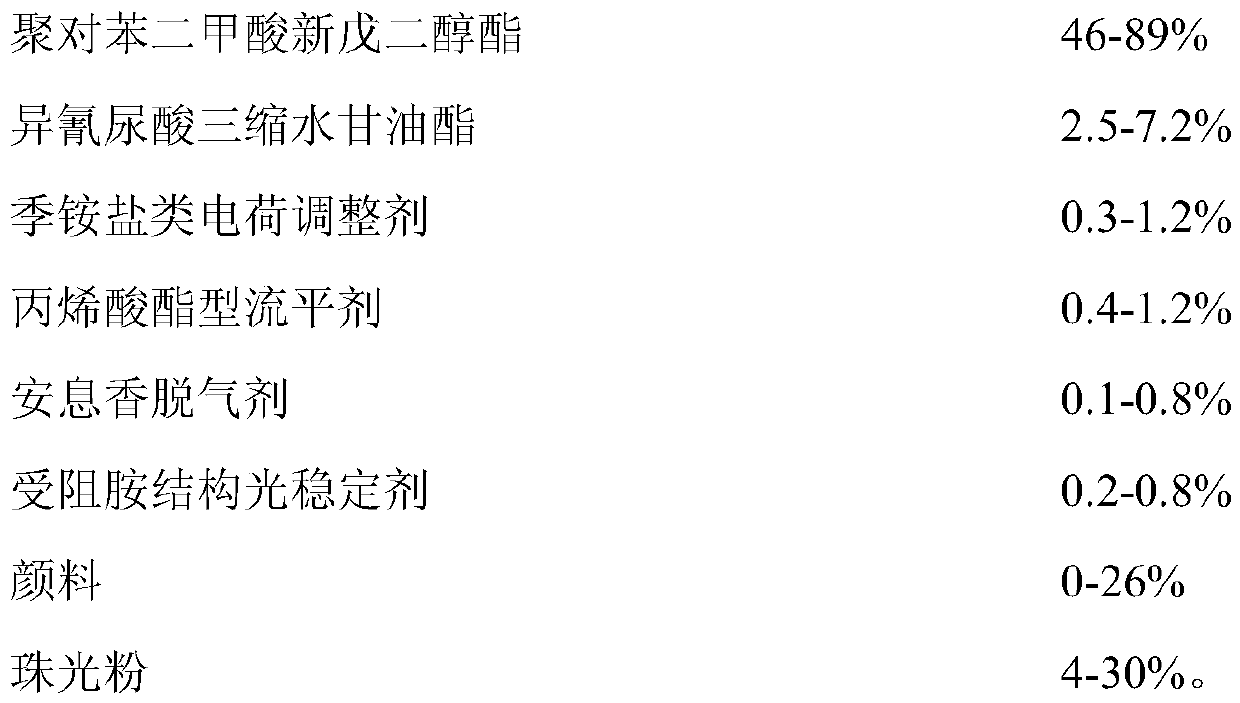

[0038] The composition of raw materials is as follows, in weight percentage:

[0039]

[0040] The acid value of polyneopentyl terephthalate is 28 mgKOH / g.

[0041] The quaternary ammonium salt charge regulator is 3-lauramidopropyl trimethylammonium methyl sulfate methyl ester.

[0042] The hindered amine structural light stabilizer is Tinuvin 144 from BASF.

[0043] Put the raw materials into the supercritical reactor and mix evenly, control the CO in the reactor 2 The content is 38wt%, the temperature is 66℃, and the pressure is 110Kg / cm 2 , The outlet temperature is 58℃. The pearl powder particles are partially or completely wrapped, and the whole powder coating particles are micro-spherical pearl powder composite powder coatings.

[0044] The specific properties of the product of Example 1 are shown in Table 1.

Embodiment 2

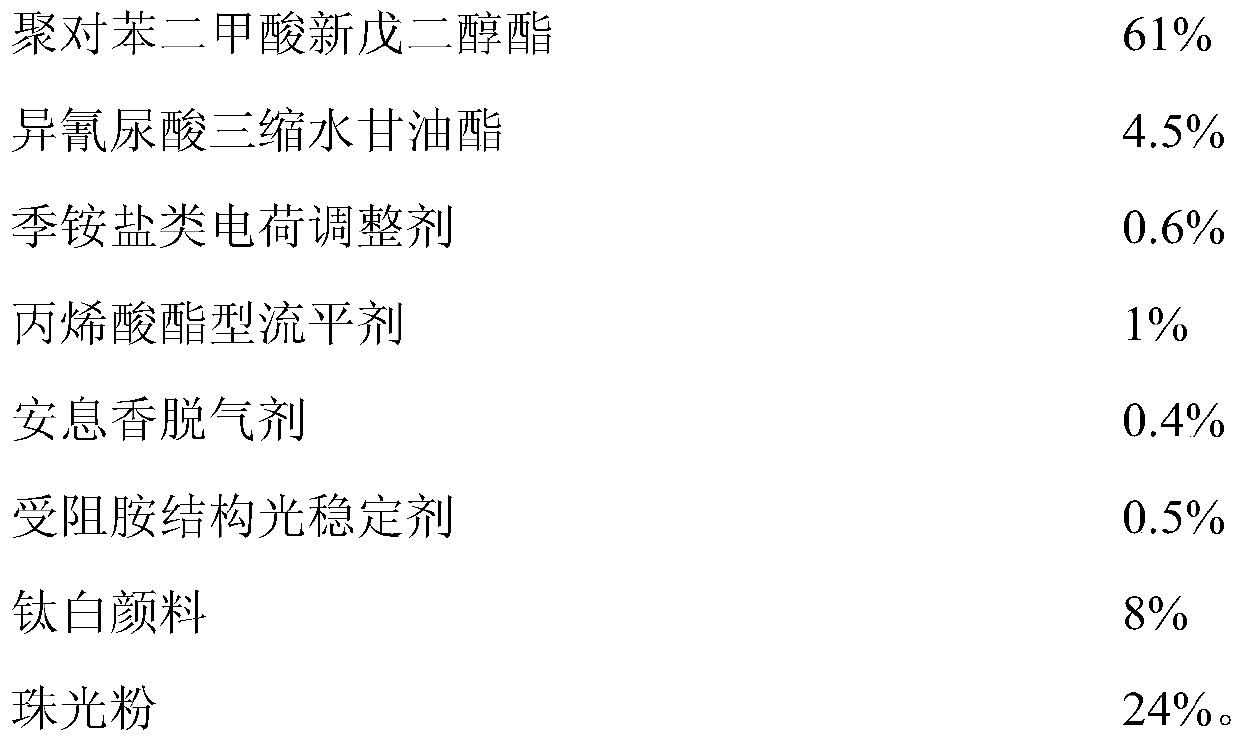

[0046] The composition of raw materials is as follows, in weight percentage:

[0047]

[0048] The acid value of polyneopentyl terephthalate is 40 mgKOH / g.

[0049] The quaternary ammonium salt charge regulator is 3-lauramidopropyl trimethylammonium methyl sulfate methyl ester.

[0050] The hindered amine structural light stabilizer is Tinuvin 144 from BASF.

[0051] Put the raw materials into the supercritical reactor and mix evenly, control the CO in the reactor 2 The content is 26wt%, the temperature is 52℃, and the pressure is 95Kg / cm 2 , The outlet temperature is 56℃. The pearl powder particles are partially or completely wrapped, and the whole powder coating particles are micro-spherical pearl powder composite powder coatings.

[0052] The specific properties of the product of Example 2 are shown in Table 1.

Embodiment 3

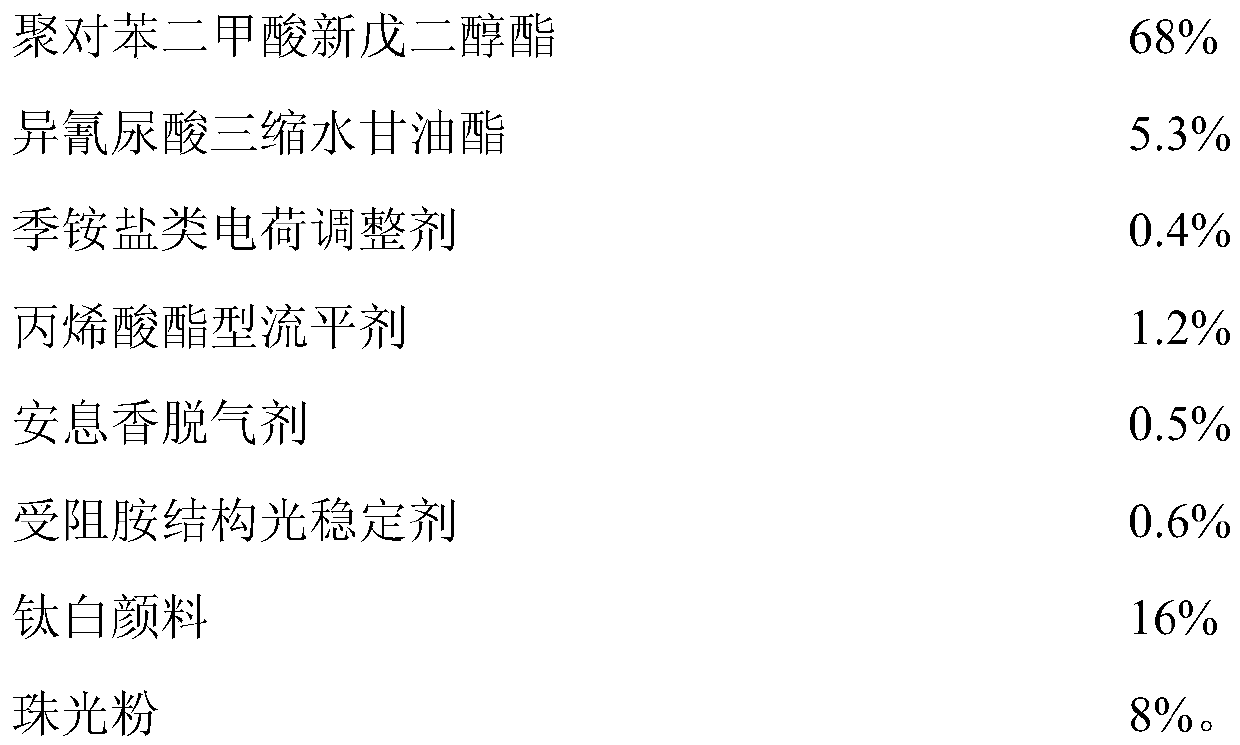

[0054] The composition of raw materials is as follows, in weight percentage:

[0055]

[0056]

[0057] The acid value of polyneopentyl terephthalate is 30 mgKOH / g.

[0058] The quaternary ammonium salt charge regulator is 3-lauramidopropyl trimethylammonium methyl sulfate methyl ester.

[0059] The hindered amine structural light stabilizer is Tinuvin 144 from BASF.

[0060] Put the raw materials into the supercritical reactor and mix evenly, control the CO in the reactor 2 The content is 42wt%, the temperature is 49℃, and the pressure is 115Kg / cm 2 , The outlet temperature is 60℃. The pearl powder particles are partially or completely wrapped, and the whole powder coating particles are micro-spherical pearl powder composite powder coatings.

[0061] The specific properties of the product of Example 3 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com