Nickel-imitative (nickel-free) current-free acid-free liquid chemical reaction electroplating process

A technology of chemical reaction and electroplating process, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of polluted environment, poor quality of gold-plated surface coating, low product reliability, industrial waste water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

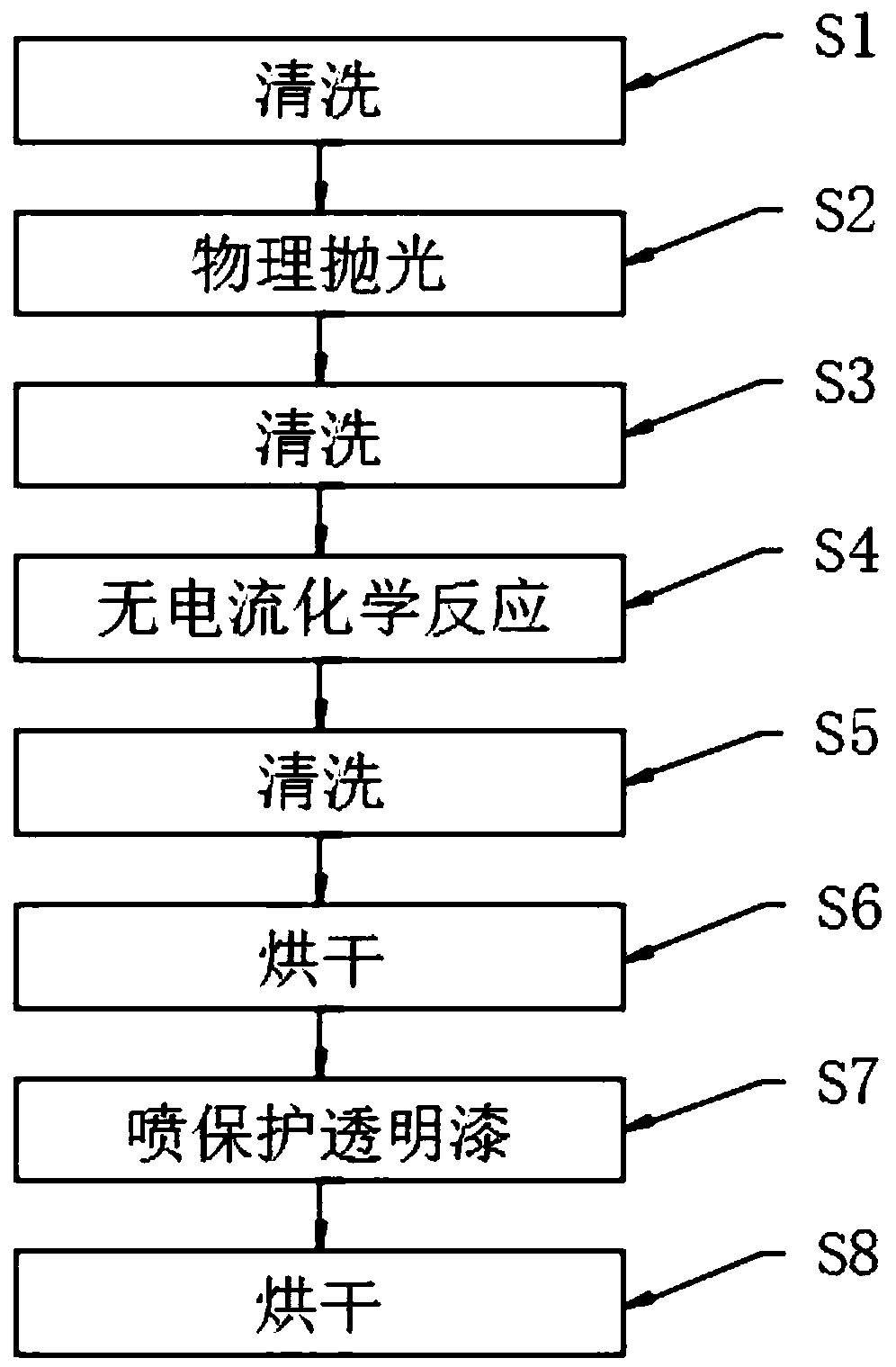

[0024] A kind of imitation nickel (nickel-free nickel) no current no acid liquid chemical reaction electroplating process, comprising the following steps:

[0025] Step S1. Cleaning: it is degreasing and decontamination treatment. Oil stains will make the adhesion of the coating worse, and the coating will crack, foam and fall off. Before coating, degreasing treatment should be carried out. The cleaning liquid composition is: 100% water Add washing powder, the ratio is 200:1, pour the dispensed detergent into the drum machine, then put the product, roll for 15, and then rinse with clean water for 3 minutes;

[0026] Step S2, physical polishing: change the physical properties of the product surface through the friction between the products to make the product surface smooth. In step S1, the surface of the product cleaned in step S1 is polished, and the ratio of product to water is 20:1 water Put it into the drum grinder and roll it for 30 minutes to remove the surface of the pr...

Embodiment 2

[0035] A kind of imitation nickel (nickel-free nickel) no current no acid liquid chemical reaction electroplating process, comprising the following steps:

[0036] Step S1. Cleaning: it is degreasing and decontamination treatment. Oil stains will make the adhesion of the coating worse, and the coating will crack, foam and fall off. Before coating, degreasing treatment should be carried out. The cleaning liquid composition is: 100% water Add washing powder, the ratio is 200:1, pour the dispensed detergent into the drum machine, then put the product, roll for 15, and then rinse with clean water for 3 minutes;

[0037] Step S2, physical polishing: change the physical properties of the product surface through the friction between the products to make the product surface smooth. In step S1, the surface of the product cleaned in step S1 is polished, and the ratio of product to water is 20:1 water Put it into the drum grinder and roll it for 40 minutes to remove the surface of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com