1000MW ultra-supercritical tower-type furnace advanced denitration running method

An ultra-supercritical, tower furnace technology, applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problem of unreasonable and effective control, unable to adjust normally, and the adjustment scheme of secondary air baffle does not meet the requirements of the scene. actual situation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0019] Step 1: Determine NOx emissions.

[0020] 1. Theoretical analysis:

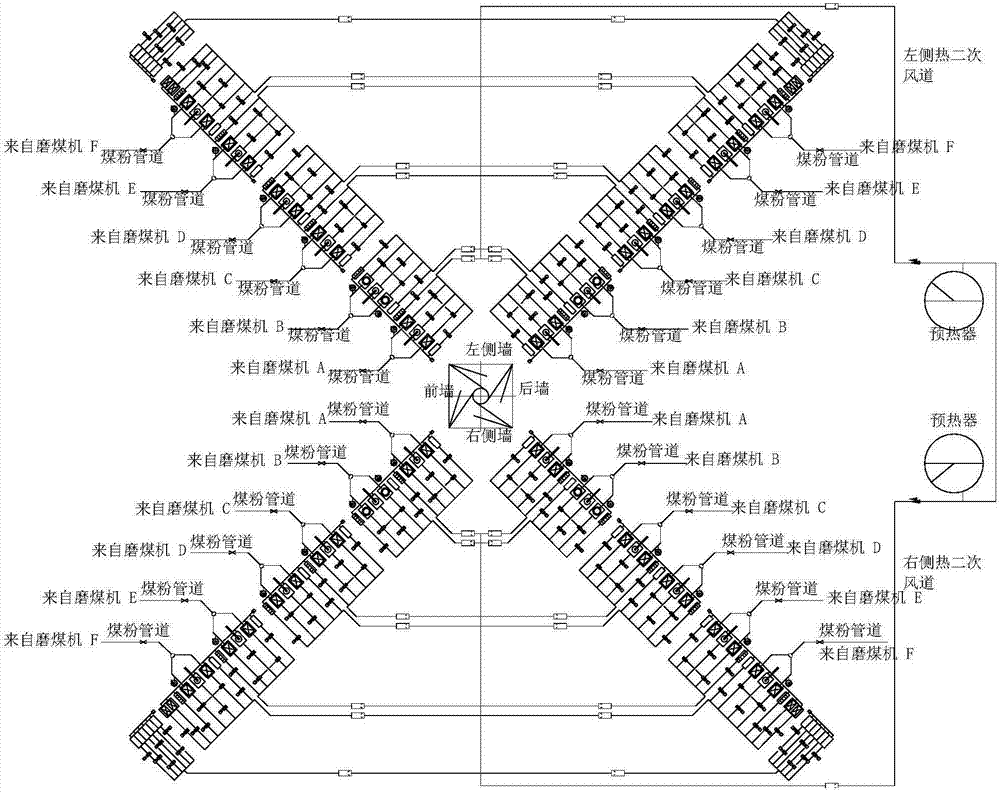

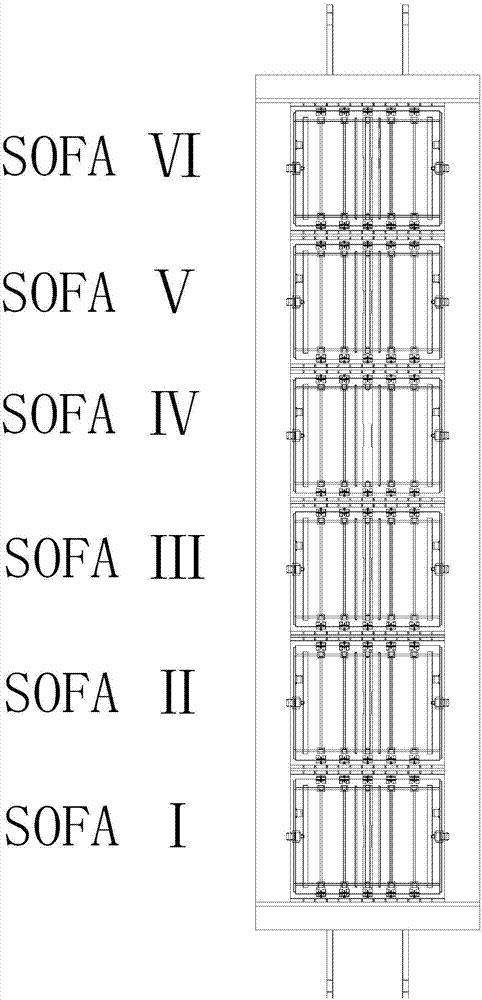

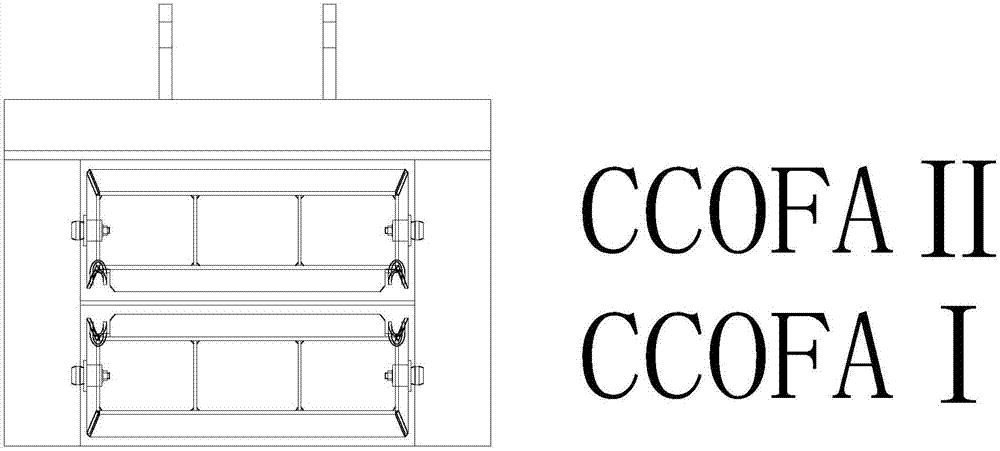

[0021] By adopting air staged combustion technology, it is possible to adjust the oxygen supply in the main combustion area of the lower layer and adjust the degree of oxygen deficiency in this area to achieve the effect of controlling the amount of NOx produced.

[0022] The more anoxic the lower main combustion area is, the lower the NOx emissions will be; however, it may lead to a decrease in combustion efficiency, an increase in incomplete combustion losses, and a decrease in boiler efficiency.

[0023] 2. Test to determine:

[0024] During the high and low load combustion performance efficiency test of the 1000MW tower furnace, it was found that when the NOx emission was less than 170mg / Nm 3 When , the loss of incomplete combustion of the boiler increases significantly, and the efficiency of the boiler decreases significantly. Therefore, it is determined that the NOx is 170-190mg / Nm 3 for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com