Terahertz lens based on metal plates

A terahertz lens and metal plate technology, applied in the field of terahertz lenses, can solve problems such as difficult control of precision and dangerous operation, and achieve the effects of small dispersion, easy manufacture, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

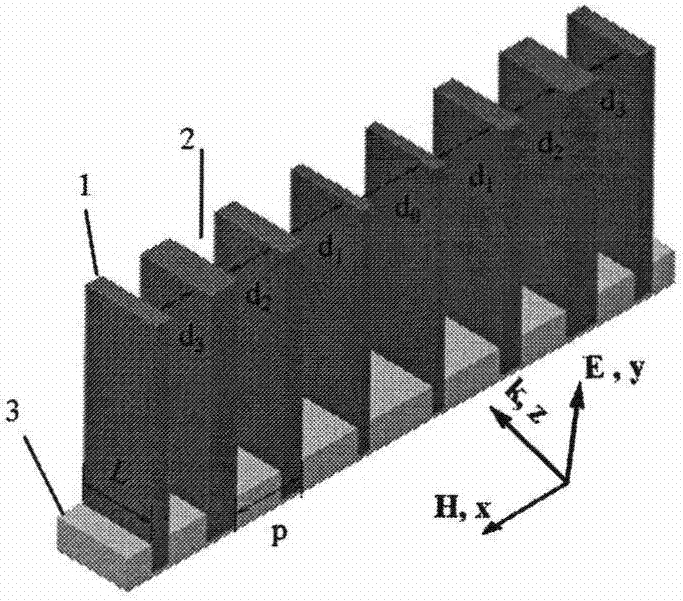

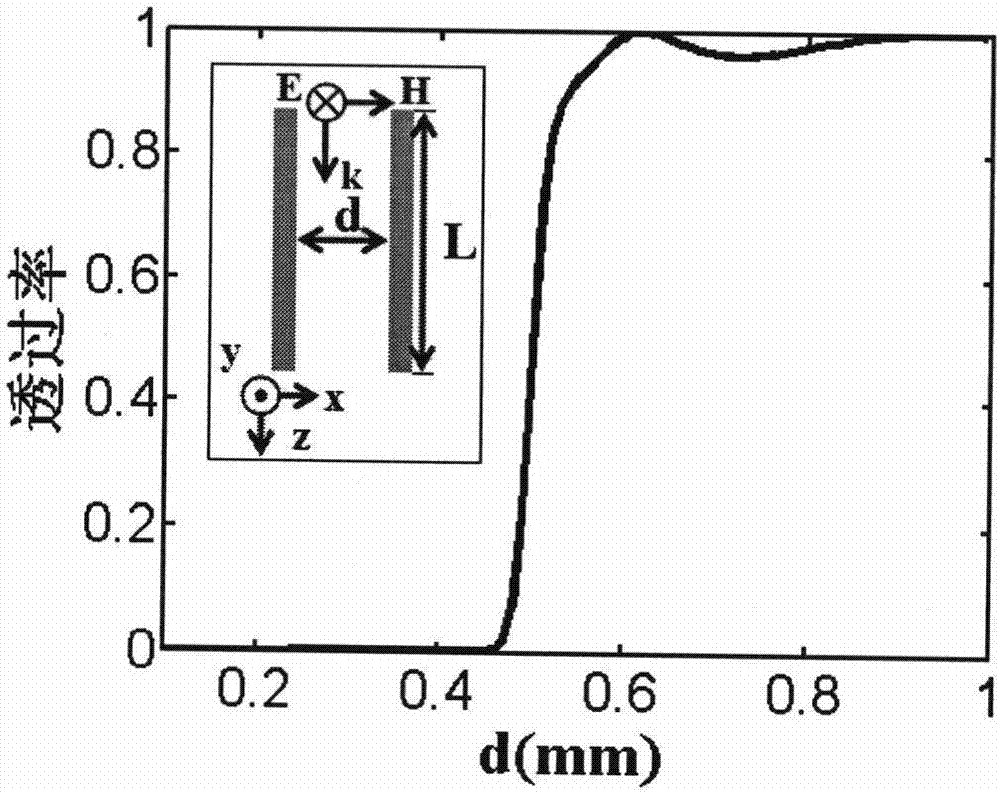

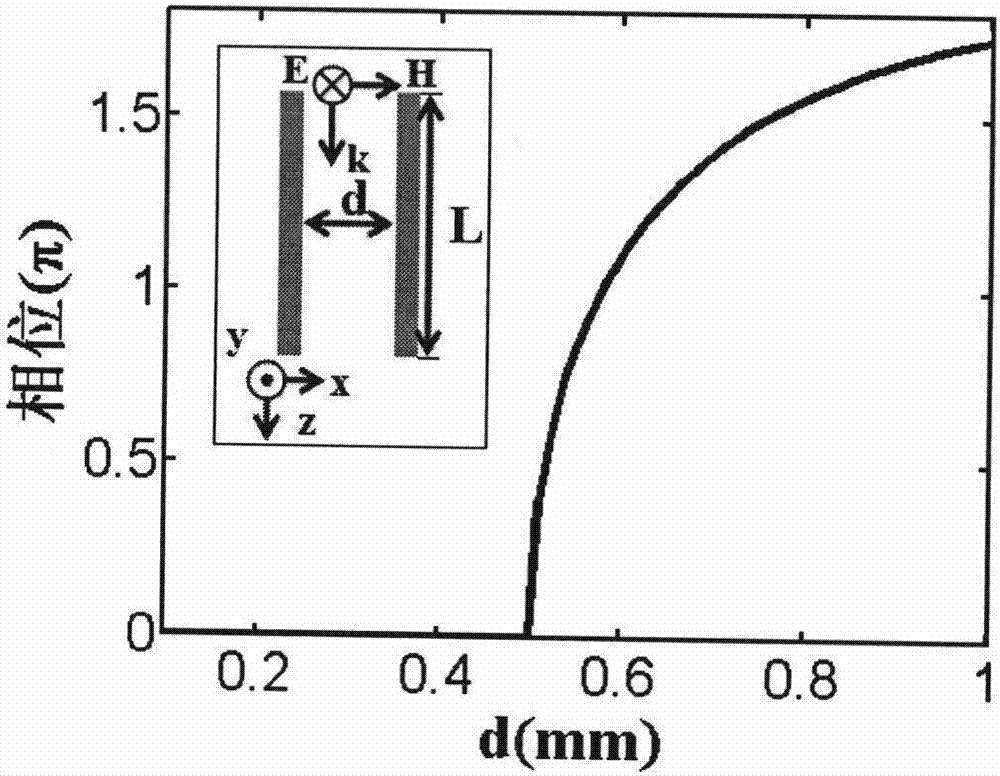

[0029] Design a working wavelength as λ d = 1 mm, Φ 0 =1.66π, lens example with focal length f=10mm, period p=1mm, composed of eighteen metal plates, with seventeen metal plate gaps, according to the propagation constant formula and the phase distribution formula, the d corresponding to the phase is calculated value, as shown in Table 1 below.

[0030] Table 1

[0031] d 0

[0032] Arrange the metal plates in parallel according to the corresponding relationship in Table 1, resulting in Figure 4 The electric field strength distribution shown. Figure 4 The xz section electric field distribution diagram obtained when the focal length of the terahertz lens is designed for embodiment 1 of the present invention is f=10mm, it can be seen from the figure that the electromagnetic wave propagates through the terahertz lens based on the metal flat plate in this embodiment (the port is at z= 0.5mm) and began to converge, and at z = 10.5mm can be observed obvious focusing...

Embodiment 2

[0034] In another specific embodiment of the present invention, design a working wavelength as λ d = 1 mm, Φ 0 =1.66π, lens example with focal length f=15mm, period p=1mm, composed of twenty-eight metal plates, with twenty-seven metal plate gaps, calculated by the propagation constant formula and the phase distribution formula corresponding to the phase The value of d is shown in Table 2 below.

[0035] Table 2

[0036] d 0

d 1

d 2

d 3

d 4

d 5

d 6

d 7

d 8

d 9

d 10

d 11

d 12

d 13

x(mm) 0 ±1 ±2 ±3 ±4 ±5 ±6 ±7 ±8 ±9 ±10 ±11 ±12 ±13 Φ(π) 1.66 1.56 1.39 1.07 0.61 0.04 1.35 0.55 1.66 0.67 1.6 0.46 1.24 0 d(mm) 0.9 0.82 0.695 0.59 0.525 0.5 0.677 0.52 1.66 0.531 0.83 0.514 0.637 0.5

[0037] Arrange the metal plates in parallel according to the corresponding relationship in Table 2, resulting in Figure 6 The electric field strength distribution shown. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com