A Process Structured Ozone System Based on Object Control

An object control and structuring technology, applied in the field of water treatment, can solve problems such as program readability, poor reusability, affecting design and debugging work efficiency, and low system stability, so as to improve versatility and readability , improve repeatability, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

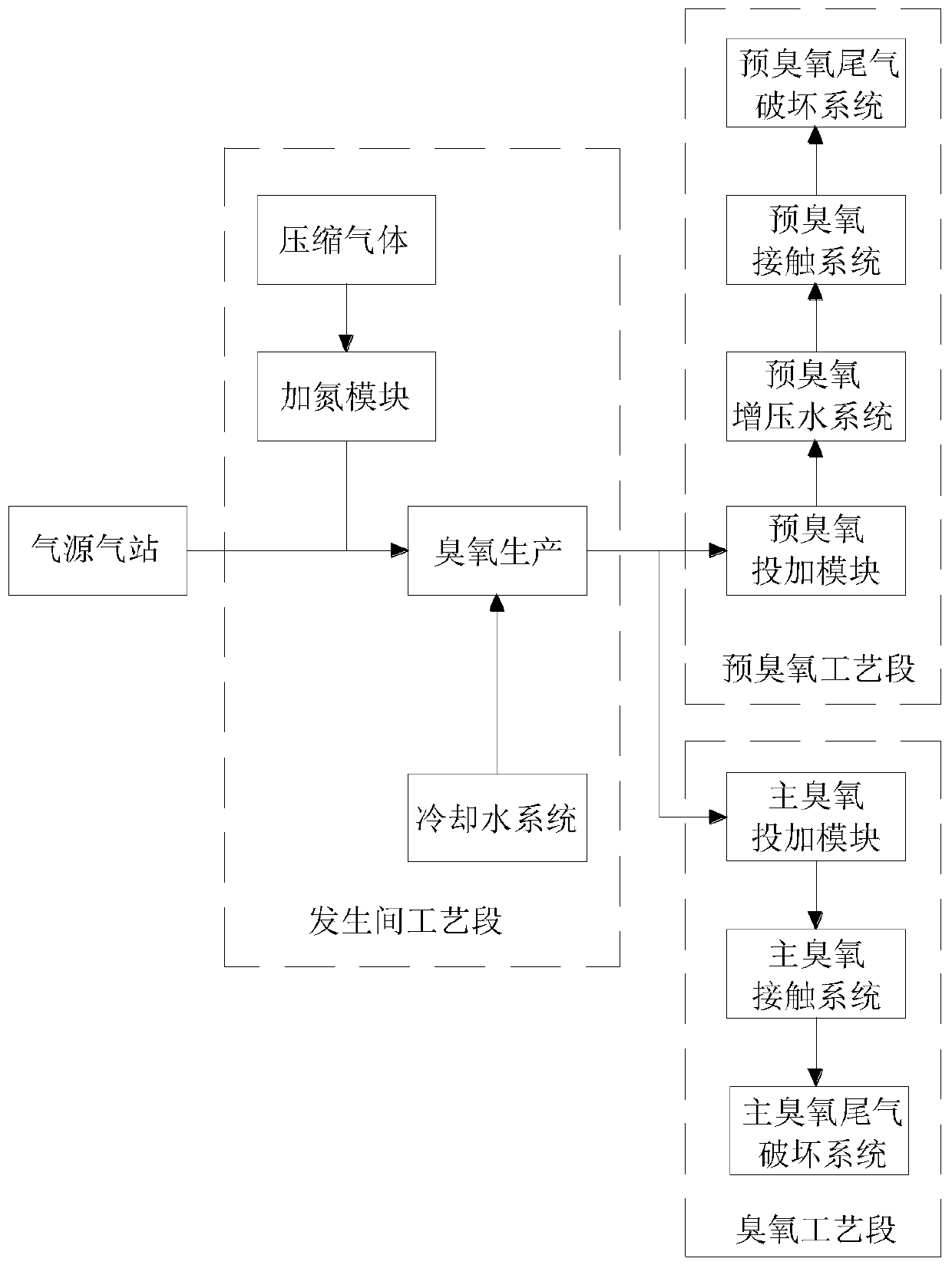

Method used

Image

Examples

Embodiment Construction

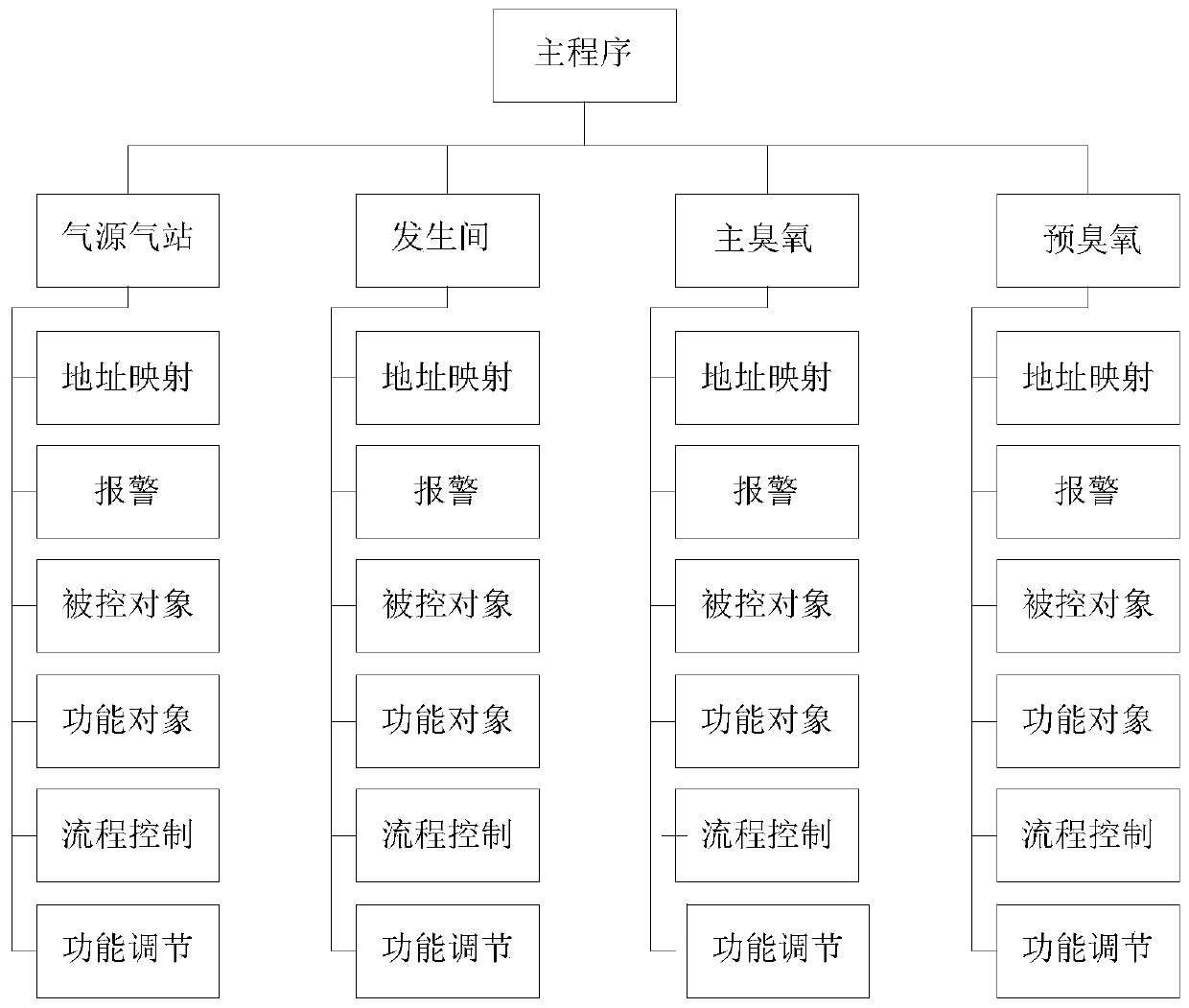

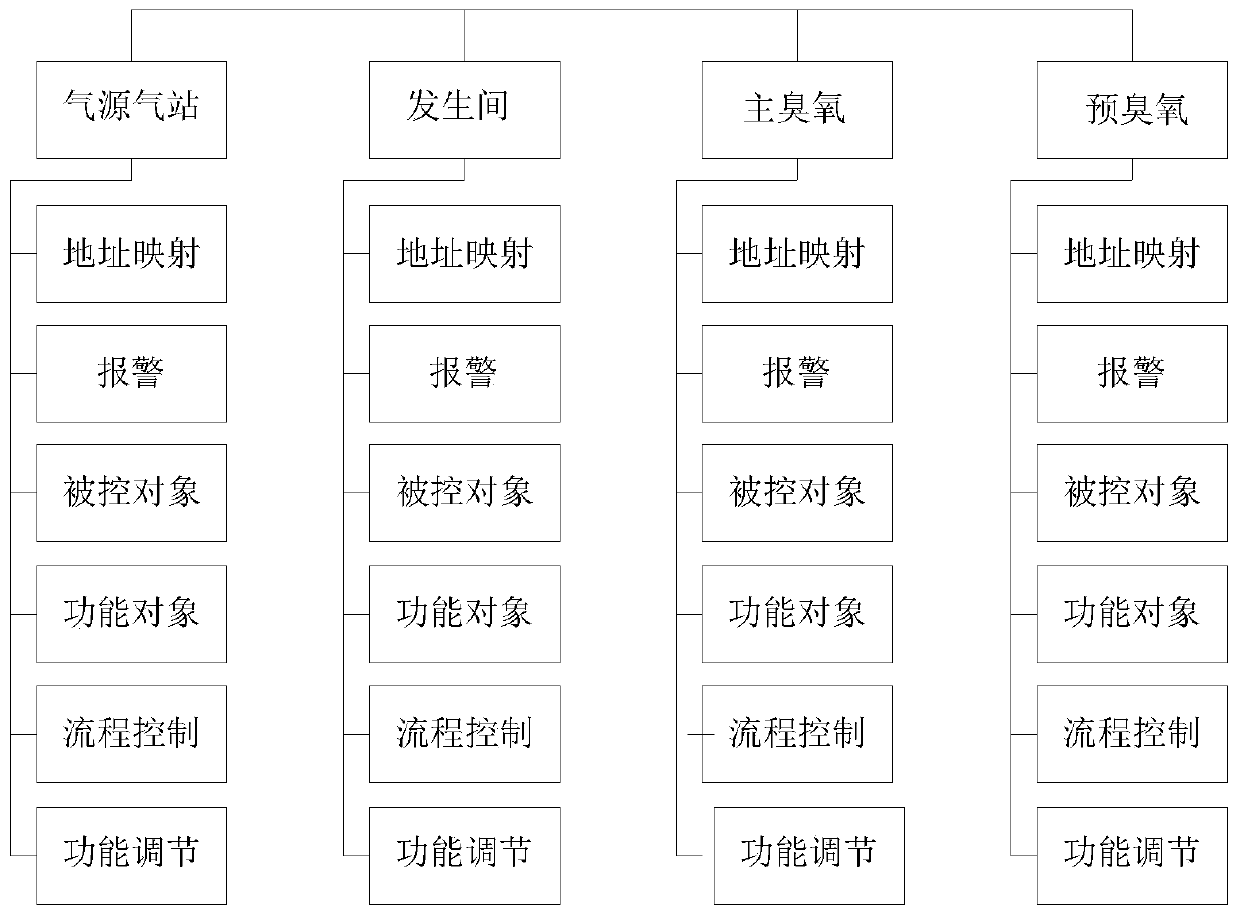

[0051] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0052] The present invention mainly involves two main points:

[0053] 1. Establishment of program standardization components

[0054] The standardized components are mainly to improve the reusability of the program, and at the same time improve the standardized components in the continuous application process. So as to improve the operation reliability of the whole ozone system.

[0055] There are two types of standardized components in the automatic control system: actual controlled objects and functional objects. The actual controlled objects are the equipment and valves in the system; the functional objects are data calculation, process control, adjustment parameter preset, etc.

[0056] Standardized components encapsulate data and logic based on certain objects and functional categories, and do not need unified interfaces and interface data type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com