Method for returning corn straw under ridges

A technology of corn stalks and ridges, applied in fertilization methods, botanical equipment and methods, horticulture, etc., can solve the problems of lack of field returning technology and methods, achieve remarkable moisture conservation effects, promote straw decomposition, and increase soil surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

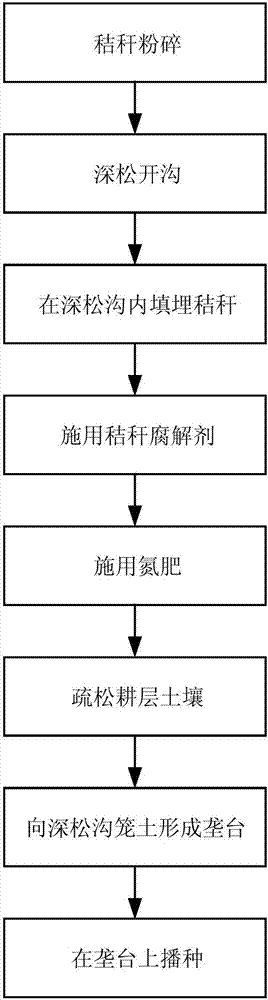

[0029] This embodiment is a method of returning corn stalks to the field under the ridge platform. The process of this method is as follows: figure 1 shown, including the following specific steps:

[0030] Step 1: Straw crushing. After the corn is harvested, it is taken away from the farmland together with the straw. Use a straw grinder and other tools to crush the straw, and the length of the crushed straw should be less than 15cm.

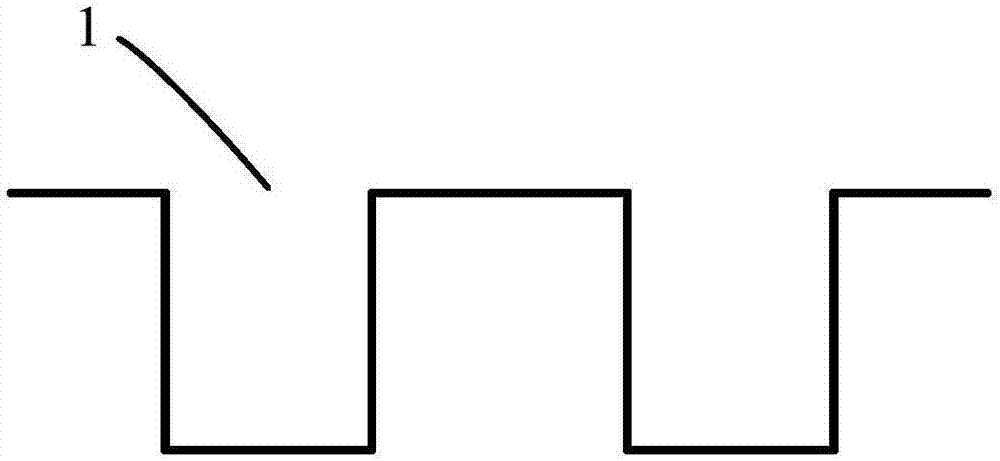

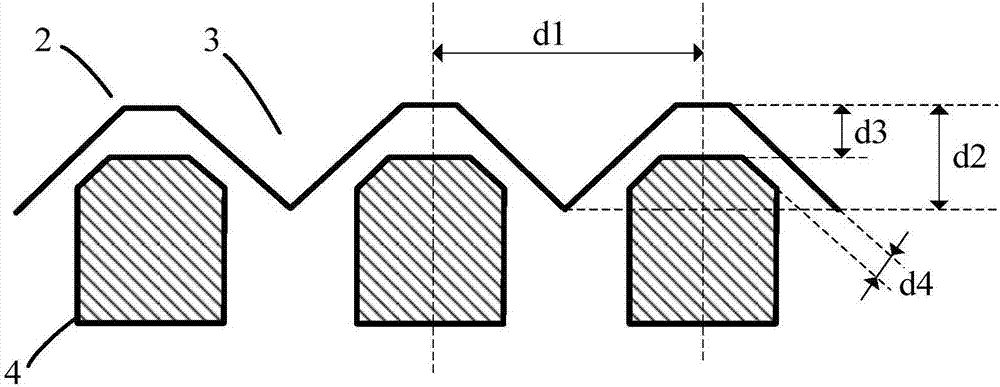

[0031] Step 2: Deep Loosening Ditch. Perform deep loosening and ditching operations at equal intervals in the farmland, and place the excavated soil on both sides of the ditch, such as figure 2 As shown, 1 is the deep loosening ditch, the ditch depth is 25-35cm, the ditch width is 30-45cm, and the distance between adjacent ditches is 60-75cm; tools such as deep loosening shovels can be used for operation.

[0032] Step 3: Fill the straw into the deep loose ditch. Fill the crushed corn stalks into the deep loose ditch.

[0033] Step 4: Appl...

Embodiment 2

[0046] This embodiment is a method for returning corn stalks to the field under the ridge platform, including the following steps:

[0047] (1) After the corn is mature, it is harvested by a combine harvester. When harvesting, the corn stalks can be chopped into small pieces of <13cm by the harvester, and distributed in strips on the soil surface.

[0048] (2) After the corn is harvested, the corn stubble cutter is used to remove the stubble of the corn.

[0049](3) Sprinkle 30kg / ha of microbial agent to promote straw decomposition and 100kg / ha of urea (combined with pure nitrogen 46kg / ha) to corn stalks.

[0050] (4) Use a subsoiling shovel to deeply loosen the furrows on the farmland. The depth of the ditch is 35-40 cm, the width of the ditch is 30-40 cm, and the distance between adjacent ditches is 60-75 cm. While ditching, put the straw mixed with microbial agent and nitrogen fertilizer into the deep loosening ditch, then backfill the ditch with soil, and mix well with it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com