Backwashing water purification system

A water purification system and backwashing technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. It can solve problems such as time-consuming, affecting the use effect, and difficult to clean. , to achieve the effect of improving fluidity and reducing internal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

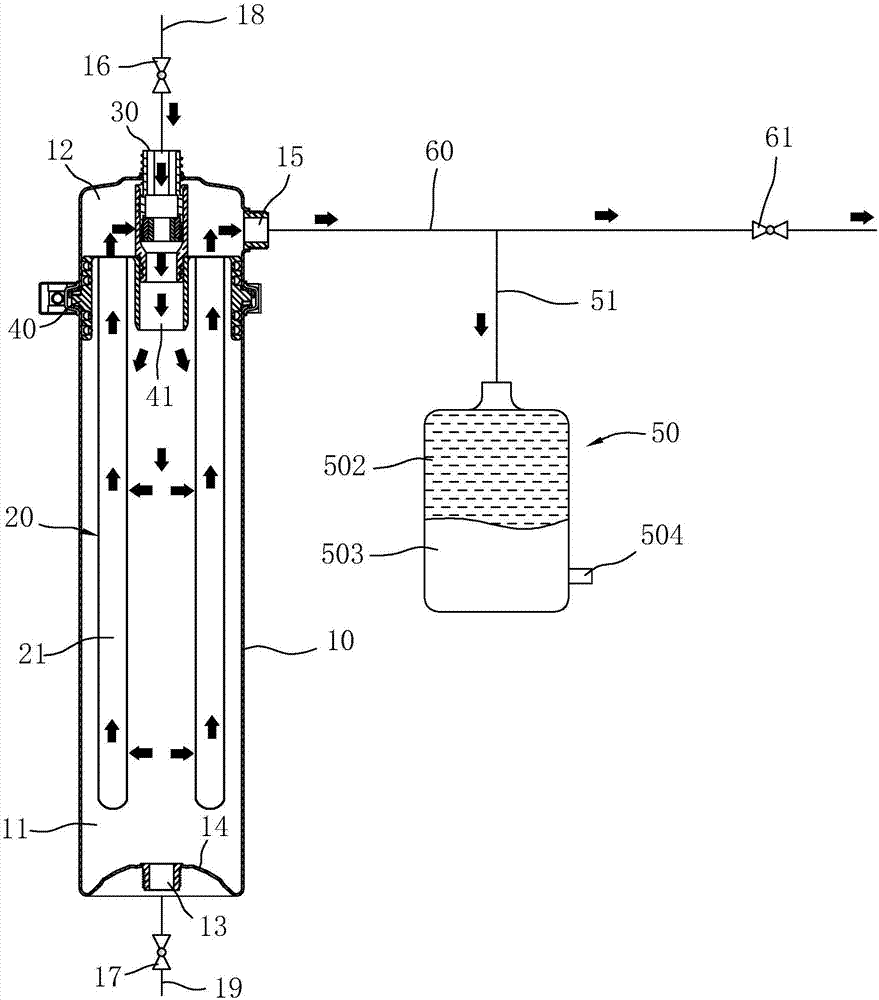

[0041] see figure 1 , a backwashing water purification system, comprising an ultrafiltration membrane assembly and a backwashing device connected with the ultrafiltration module assembly. The ultrafiltration membrane assembly includes a housing 10, which is provided with a water inlet, a sewage outlet 13 and a clean water outlet 15, wherein the water inlet and the sewage outlet 13 are respectively located at both ends of the housing 10, and the clean water outlet 15 is opened on the on the side wall of the housing 10.

[0042] Several hollow fiber membranes 20 are also arranged in the casing 10, and one end of several hollow fiber membranes 20 is fixed on the head 40, and the head 40 is fixed in the casing 10, and the casing 10 is divided into two chambers by the head 40 chambers, wherein several hollow fiber membranes 20 are located in one of the chambers, which is a high-pressure chamber 11 , and the opposite chamber is a low-pressure chamber 12 .

[0043] The hollow fiber...

Embodiment 2

[0055] see Figure 5 The difference between a backwashing water purification system and Embodiment 1 is that the backwashing device uses a water storage bucket 52 in conjunction with a water pump 53 to replace the pressure bucket 50 . The return pipeline 51 is also connected to the water purification pipeline 60, and the water pump 53 is connected to the water storage bucket 52. The water storage bucket 52 has a water purification opening 521, and the water purification opening 521 passes through the first water purification branch 55 and the water purification pipeline 60. connected, and a float switch 56 is provided at the clean water opening 521, and a second valve 54 is provided on the return line 51.

[0056] When the system is producing water, the first valve 61 and the water inlet valve 16 are opened, and the drain valve 17 and the second valve 54 are closed. After the same raw water is ultra-filtered, the purified water enters the purified water pipeline 60 from the pu...

Embodiment 3

[0059] see Figure 7 , a backwashing water purification system differs from Embodiment 2 in that the number of water storage tanks 52 is increased. In this embodiment, two water storage tanks 52 connected in series are used, and a connecting pipe 57 is used between the two water storage tanks 52. interconnected. Furthermore, the capacity of flushing water during backwashing is increased, and the water storage capacity is also improved. Of course, the number of series connection of water storage buckets 52 can be selected according to actual conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com