Sintering raw material and preparation method thereof

A raw material and fuel technology, applied in the field of sintered raw materials and its preparation, can solve the problems of high green ball rate, decreased strength of finished balls, insufficient combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Put the fly ash and shale into the mixer and stir to obtain a homogeneous mixture; measure the loss on ignition of the homogeneous mixture, if the loss on ignition is less than 6.7%, add sludge, bentonite and silica mud to it to adjust the final The loss on ignition is 6.7-7.73%; if the loss on ignition is greater than 7.73%, further add shale, bentonite and petroleum catalyst to adjust the final loss on ignition to 6.7-7.73%. The mixture was granulated, preheated at 500°C for 20 minutes and then sintered at 1100°C to obtain ceramsite. Observe whether there is obvious ball explosion and agglomeration during the sintering process, and measure the green ball rate in the sintered product.

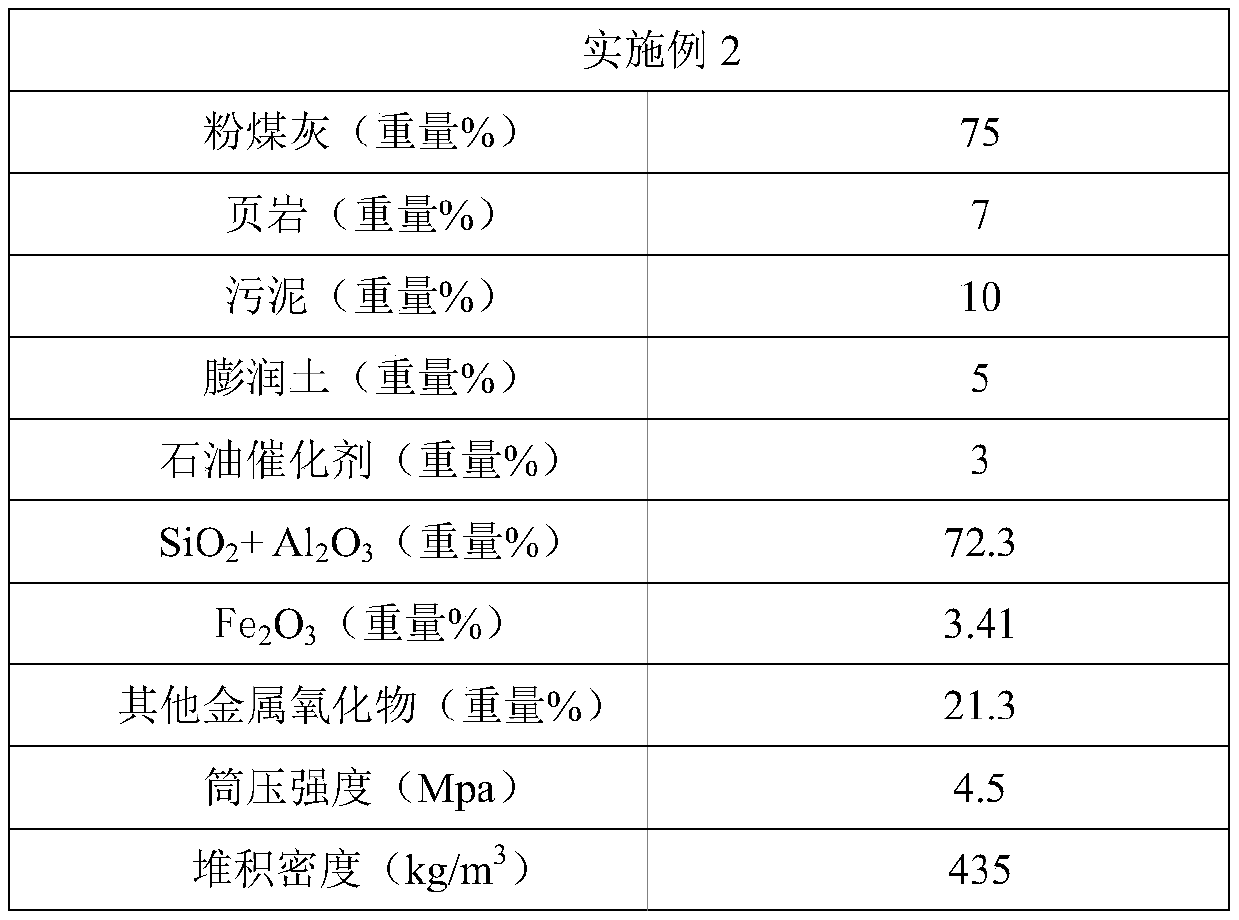

Embodiment 2

[0024] Batching and sintering process of embodiment 2 ultra-light ceramsite

[0025] The fly ash of 75 weight parts, the shale of 7 weight parts are put into agitator and stirred, obtain homogeneous mixture; Measure the loss on ignition and SiO of this homogeneous mixture 2 、Al 2 o 3 , Fe 2 o 3 According to the measurement results, sludge is further added to the mixture to adjust the loss on ignition, and petroleum catalysts and bentonite are added to adjust the SiO2 content. 2 、Al 2 o 3 , Fe 2 o 3 content of metal oxides. Make the loss on ignition of the mixture in the range of 6.7-7.37%; SiO 2 +Al 2 o 3 The weight percentage is in the range of 72.27%-78.2%, Fe 2 o 3 The weight percentage of Ca, Mg, K, Na and other metal oxides is in the range of 17.58-21.35%. After adjusting the ignition loss and chemical composition of the mixture to the above range, the mixture is granulated, preheated at 500°C for 20 minutes, and then sintered at 1100°C to obtain ceramsite. ...

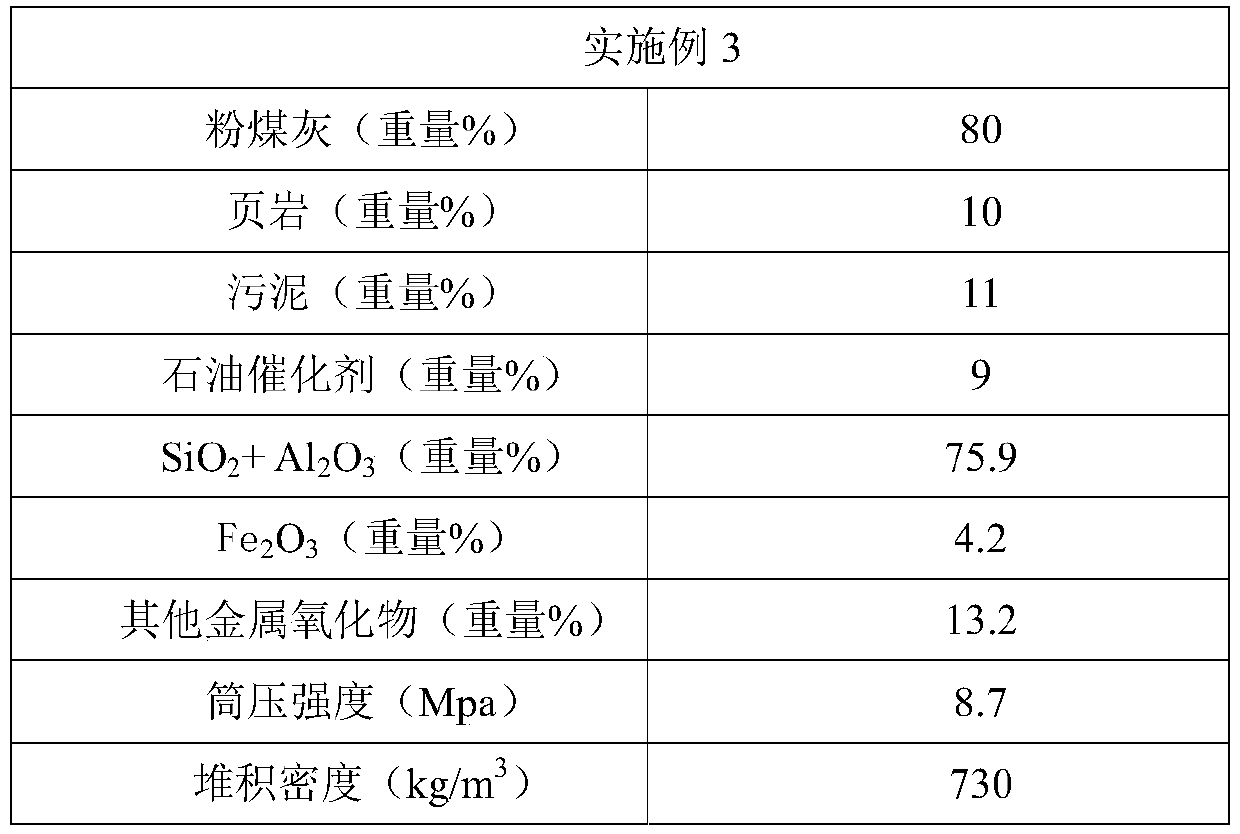

Embodiment 3

[0029] The batching and sintering process of embodiment 3 high-strength ceramsite

[0030] The fly ash of 80 weight parts, the shale of 10 weight parts are put into agitator and stirred, obtain homogeneous mixture; Measure the loss on ignition and SiO of this homogeneous mixture 2 、Al 2 o 3 , Fe 2 o 3 According to the measurement results, sludge is further added to the mixture to adjust the loss on ignition, and a petroleum catalyst is added to adjust the SiO 2 、Al 2 o 3 , Fe 2 o 3 content of metal oxides. Make the loss on ignition of the mixture in the range of 6.7-7.37%; SiO 2 +Al 2 o 3 The weight percentage is in the range of 75.3%-77.92%, Fe 2 o 3 The weight percentage of Ca, Mg, K, Na and other metal oxides should be less than 16.43%. Adjust the ignition loss and chemical composition of the mixture to the above range, then granulate, preheat at 500°C for 20 minutes, and then transfer to 1100°C for sintering to obtain ceramsite. Measure the cylinder compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com