Preparation method of o-dibromobenzene

A technology of o-dibromobenzene and o-bromoaniline, applied in the field of preparation of o-dibromobenzene, can solve the problems of high cost, low purity, waste of raw materials, etc., achieve low cost, easy availability of materials, and increase product purity and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

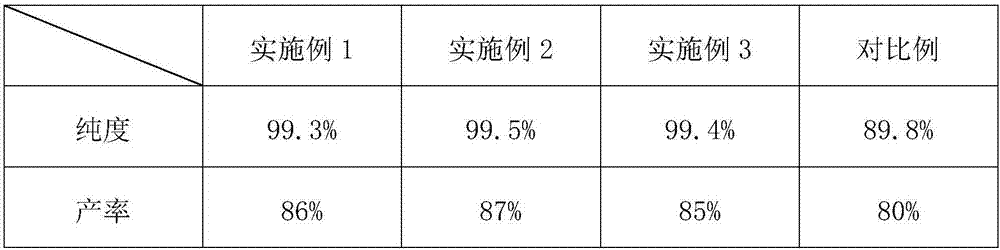

Embodiment 1

[0027] A preparation method of o-dibromobenzene, comprising the following preparation steps:

[0028] S1: Add water into the reaction kettle, then add sodium nitrite while stirring, obtain sodium nitrite solution after the dissolution is complete, and put it in a bucket for later use;

[0029] S2: Add 18 parts of hydrobromic acid with a mass fraction of 48% in the reaction kettle, add 6 parts of o-bromoaniline under stirring, and start freezing to cool down after the two are completely dissolved, and drop it below 10°C, and then add it from the manhole Cool down with ice cubes, add 8 parts of sodium nitrite solution prepared in step S1 dropwise at a temperature of 0-5°C, and stir and cool for 1 hour after the dropwise addition;

[0030] S3: Perform suction filtration within the temperature range of 0-5°C to remove impurities to obtain a diazonium salt solution;

[0031] S4: Add 7 parts of hydrobromic acid with a mass fraction of 48% in a reaction kettle equipped with a steam ...

Embodiment 2

[0036] A preparation method of o-dibromobenzene, comprising the following preparation steps:

[0037] S1: Add water into the reaction kettle, then add sodium nitrite while stirring, obtain sodium nitrite solution after the dissolution is complete, and put it in a bucket for later use;

[0038] S2: Add 20 parts of hydrobromic acid with a mass fraction of 48% in the reaction kettle, add 7 parts of o-bromoaniline under stirring, and start freezing to cool down after the two are completely dissolved, and drop it below 10°C, and then add it from the manhole Cool down with ice cubes, add 9 parts of sodium nitrite solution prepared in step S1 dropwise at a temperature of 0-5°C, and stir and cool for 1 hour after the dropwise addition;

[0039] S3: Perform suction filtration within the temperature range of 0-5°C to remove impurities to obtain a diazonium salt solution;

[0040] S4: Add 7 parts of hydrobromic acid with a mass fraction of 48% in a reaction kettle equipped with a steam ...

Embodiment 3

[0045] A preparation method of o-dibromobenzene, comprising the following preparation steps:

[0046] S1: Add water into the reaction kettle, then add sodium nitrite while stirring, obtain sodium nitrite solution after the dissolution is complete, and put it in a bucket for later use;

[0047] S2: Add 23 parts of hydrobromic acid with a mass fraction of 48% in the reaction kettle, add 8 parts of o-bromoaniline under stirring, and start freezing to cool down after the two are completely dissolved, and drop it below 10°C, and then add it from the manhole Cool down with ice cubes, add 10 parts of sodium nitrite solution prepared in step S1 dropwise at a temperature of 0-5°C, and stir and cool for 1 hour after the dropwise addition;

[0048] S3: Perform suction filtration within the temperature range of 0-5°C to remove impurities to obtain a diazonium salt solution;

[0049] S4: Add 8 parts of hydrobromic acid with a mass fraction of 48% in a reaction kettle equipped with a steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com