Probiotic agent for fermenting silage and production method thereof

A technology of silage and probiotics, applied in the field of animal husbandry, can solve the problems of high cost and unclear dosage, and achieve the effects of low production cost, high nutrition and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

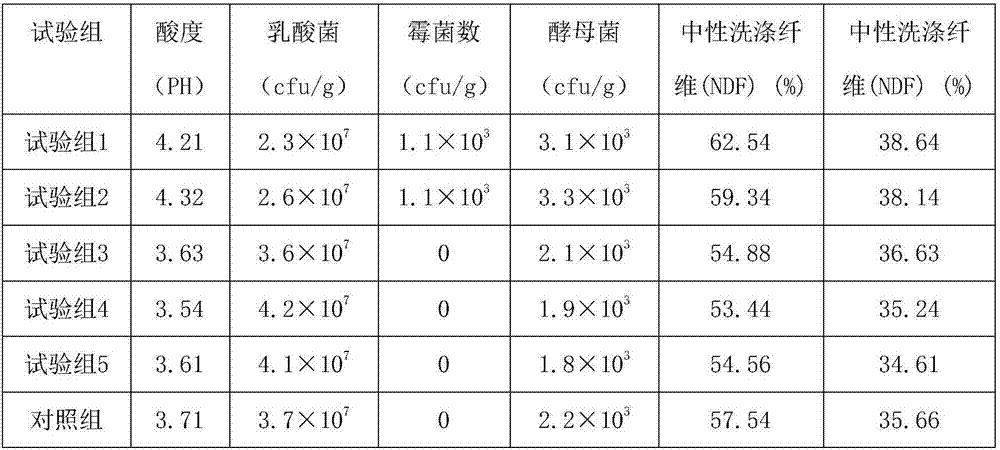

Examples

Embodiment 1

[0039] The preparation of embodiment 1 probiotics and silage preparation:

[0040] Preparation of probiotics:

[0041] (1) Preparation of medium:

[0042]Take 4L of rice washing water, add 100g of potato powder and 40g of urea, stir and mix evenly, take 100g of beef liver and grind it into fine powder, add to the mixture, stir and mix evenly, and sterilize at 120-123°C for 30 minutes;

[0043] (2) Inoculation and cultivation of probiotics:

[0044] Cool the medium prepared in step (1) to room temperature, and inoculate Bacillus subtilis 2×10 10 CFU / G, Lactobacillus 8×10 9 CFU / G, Lactobacillus sake 4×10 10 CFU / G, Lactobacillus acidophilus 3×10 10 CFU / G, the inoculum size is 1g, stir and mix to disperse the strains evenly in the culture medium, ferment aerobically at 25°C for 50h, then anaerobically ferment at 32°C for 30h, and separate in a sterile room Pack in strain bag, every bag 200ml promptly obtains the probiotic agent for fermenting silage of the present invention;...

Embodiment 2

[0046] The preparation of embodiment 2 probiotics and silage preparation:

[0047] Preparation of probiotics:

[0048] (1) Preparation of medium:

[0049] Take 4L of rice washing water, add 100g of potato powder and 40g of urea, stir and mix evenly, take 100g of beef liver and grind it into fine powder, add to the mixture, stir and mix evenly, and sterilize at 120-123°C for 30 minutes;

[0050] (2) Inoculation and cultivation of probiotics:

[0051] The medium prepared in step (1) was cooled to room temperature, and inoculated with Aspergillus niger 2 × 10 10 CFU / G, Lactobacillus 8×10 9 CFU / G, Lactobacillus sake 4×10 10 CFU / G, Lactobacillus acidophilus 3×10 10 CFU / G, the inoculum size is 1g, stir and mix to disperse the strains evenly in the culture medium, ferment aerobically at 25°C for 50h, then anaerobically ferment at 32°C for 30h, and separate in a sterile room Pack in strain bag, every bag 200ml promptly obtains the probiotic agent for fermenting silage of the pre...

Embodiment 3

[0053] The preparation of embodiment 3 probiotics and silage preparation:

[0054] Preparation of probiotics:

[0055] (1) Preparation of medium:

[0056] Take 4L of rice washing water, add 100g of potato powder and 40g of urea, stir and mix evenly, take 100g of beef liver and grind it into fine powder, add to the mixture, stir and mix evenly, and sterilize at 120-123°C for 30 minutes;

[0057] (2) Inoculation and cultivation of probiotics:

[0058] The medium prepared in step (1) was cooled to room temperature, and inoculated with Aspergillus niger 2 × 10 10 CFU / G, Bacillus subtilis 2×10 10 CFU / G, Lactobacillus 8×10 9 CFU / G, Lactobacillus sake 4×10 10 CFU / G, Lactobacillus acidophilus 3×10 10 CFU / G, the inoculum size is 1g, stir and mix to disperse the strains evenly in the culture medium, ferment aerobically at 25°C for 50h, then anaerobically ferment at 32°C for 30h, and separate in a sterile room Pack in strain bag, every bag 200ml promptly obtains the probiotic agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com