Preparation method for sturgeon protein peptides

A protein peptide, sturgeon technology, applied in the direction of fermentation, to achieve mild hydrolysis conditions, enhance the effect of enzymatic hydrolysis, and improve the effect of soluble protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

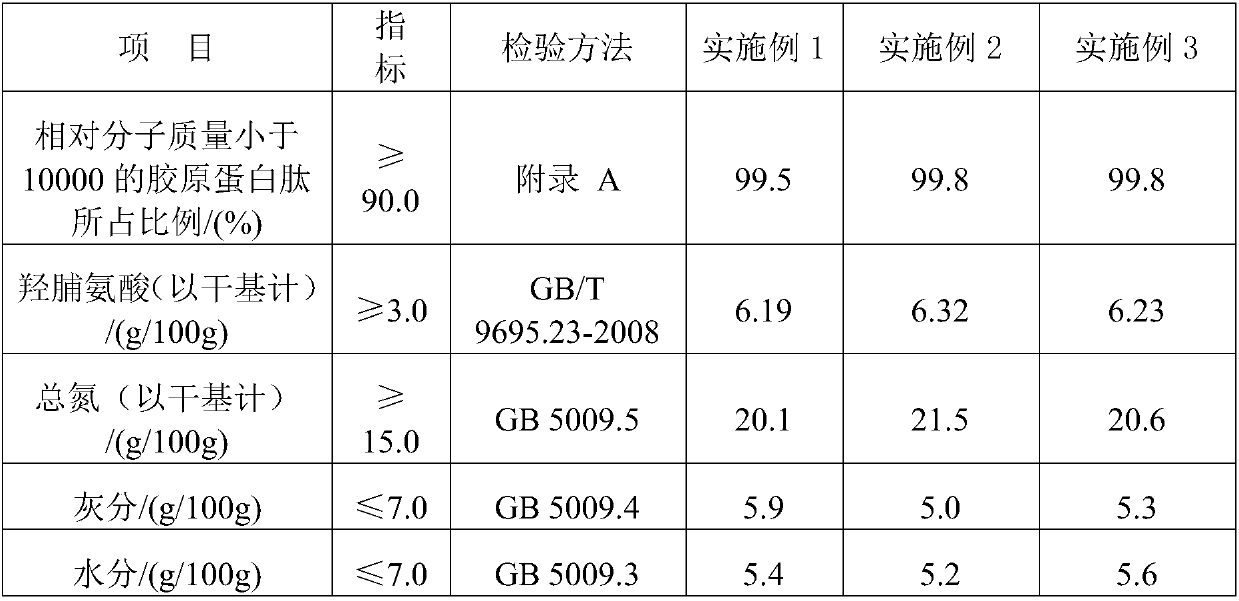

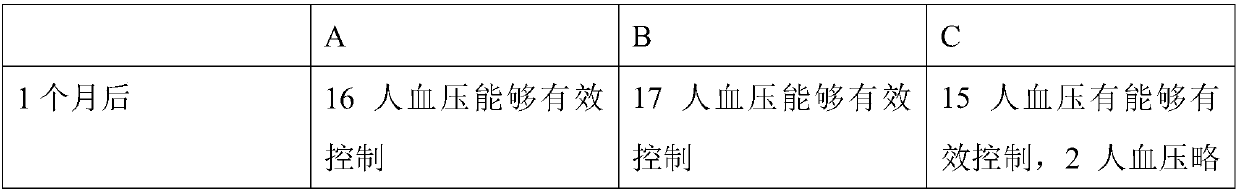

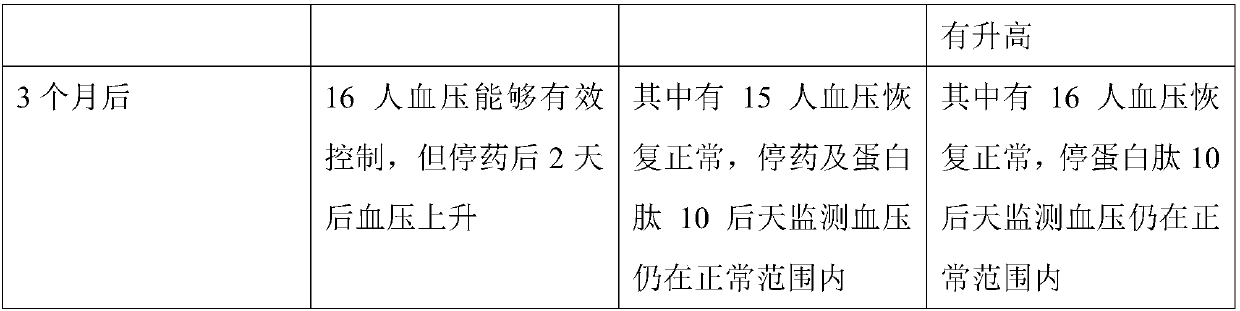

Examples

Embodiment 1

[0024] The preparation of sturgeon protein peptide comprises the following steps:

[0025] 1) Wash and cut the sturgeon into chunks, then use a meat grinder to grind it, add water 1 times its weight, raise the temperature to above 90°C and keep it for 20 minutes, and then carry out steam explosion treatment under the pressure of 2.5MPa for 3 minutes;

[0026] 2) Cool the material obtained in step 1) to below 60°C, first adjust the pH to 7.5-8, add 0.2% protease of sturgeon mass, the protease is obtained by mixing neutral protease and papain in a ratio of 1:2, and React at 50°C-55°C for 5h, then inactivate the enzyme at high temperature, then add trypsin with 0.1% mass of sturgeon and react at 35-40°C for 2h.

[0027] 3) The material obtained in step 2) is heated to above 90°C and kept for 20 minutes, and then cooled to below 65°C for decolorization. The decolorizer is obtained by mixing activated carbon and diatomaceous earth at a mass ratio of 2:1. The amount of decolorizer a...

Embodiment 2

[0029] The preparation of sturgeon protein peptide comprises the following steps:

[0030] 1) Wash the sturgeon, cut into blocks, then mince it with a meat grinder, add water twice its weight, and add 25% of the mass of the sturgeon at a concentration of 1% sodium chloride solution, and the sturgeon Glucose with a mass of 0.45% is heated to above 90°C and kept for 15 minutes, and then subjected to steam explosion treatment at a pressure of 2 MPa for 5 minutes;

[0031] 2) Cool the material obtained in step 1) to below 60°C, first adjust the pH to 7.5-8, add 0.3% protease of sturgeon mass, the protease is obtained by mixing neutral protease and papain in a ratio of 1:2, and React at 50°C-55°C for 5h, then inactivate the enzyme at high temperature, then add trypsin with 0.1% mass of sturgeon and react at 35-40°C for 2h.

[0032] 3) The material obtained in step 2) is heated to above 90°C and kept for 20 minutes, and then cooled to below 65°C for decolorization. The decolorizer ...

Embodiment 3

[0034] The preparation of sturgeon protein peptide comprises the following steps:

[0035]1) Wash the sturgeon, cut into pieces, then mince it with a meat grinder, add water three times its weight, and add 30% of the mass of the sturgeon at a concentration of 1.5% sodium chloride solution, and the sturgeon Glucose with a mass of 0.45% is heated to above 90°C for 10 minutes, and then subjected to steam explosion treatment at a pressure of 2.2MPa for 5 minutes;

[0036] 2) Cool the material obtained in step 1) to below 60°C, first adjust the pH to 7.5-8, add 0.2% protease of sturgeon mass, the protease is obtained by mixing neutral protease and papain in a ratio of 1:2, and React at 50°C-55°C for 5 hours, then inactivate the enzyme at high temperature, then add trypsin with 0.2% mass of sturgeon and react at 35-40°C for 2 hours.

[0037] 3) The material obtained in step 2) is heated to above 90°C and kept for 20 minutes, and then cooled to below 65°C for decolorization. The dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com