A high-temperature dredging device for sponge titanium distillation

A titanium sponge and high-temperature technology, which is applied in the field of high-temperature dredging devices, can solve problems such as cold-end standpipe blockage, distillation interruption, and inability to effectively judge, and achieve the effects of ensuring gas composition, reducing labor intensity, and facilitating separate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

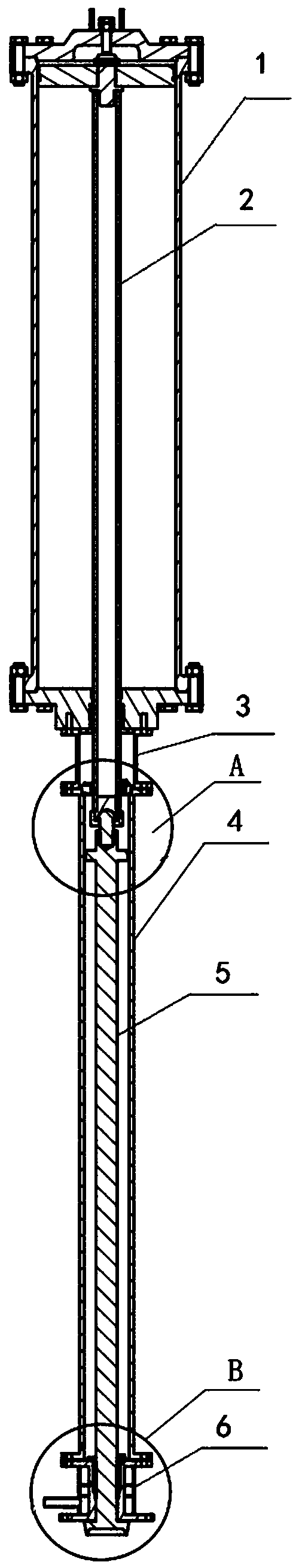

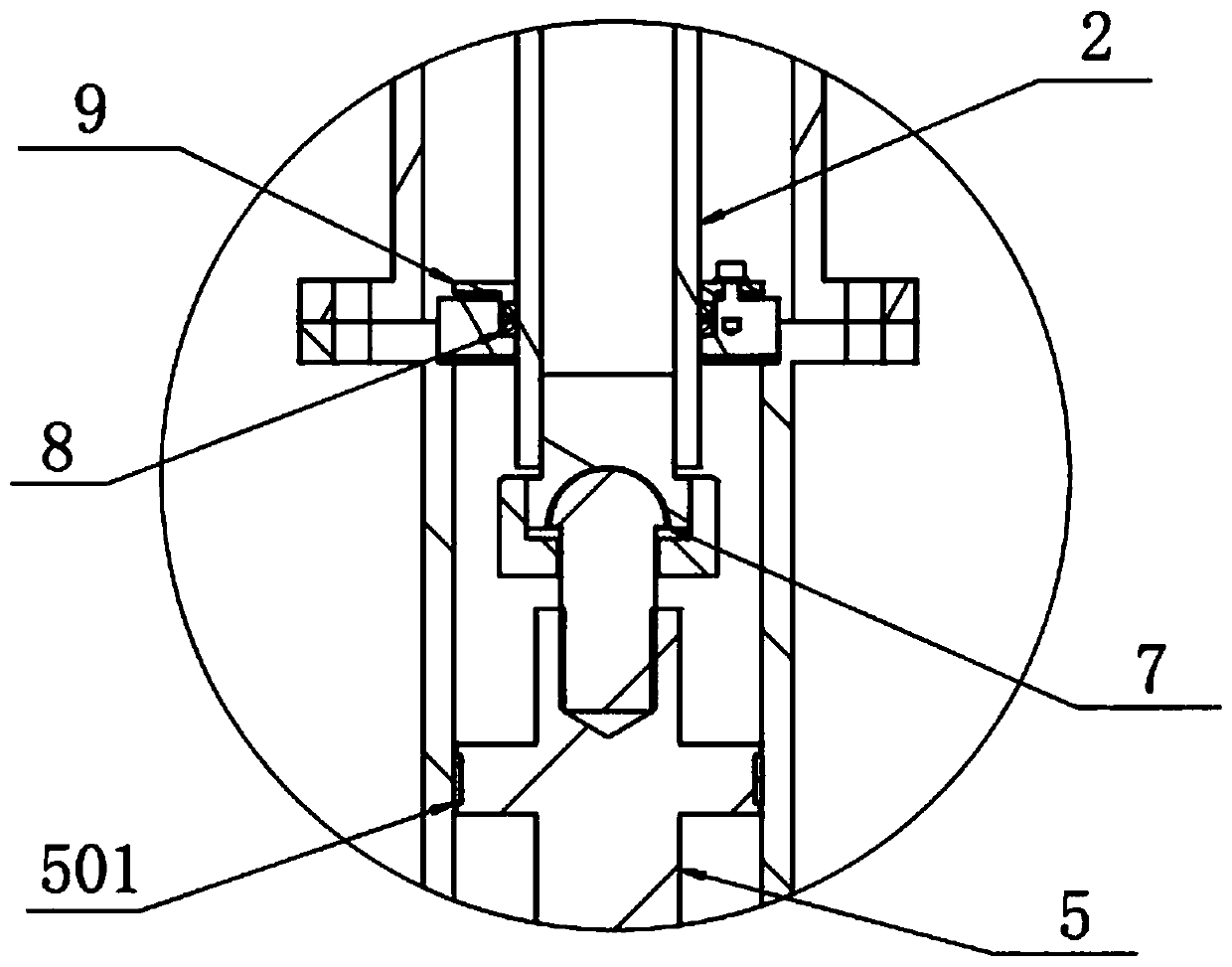

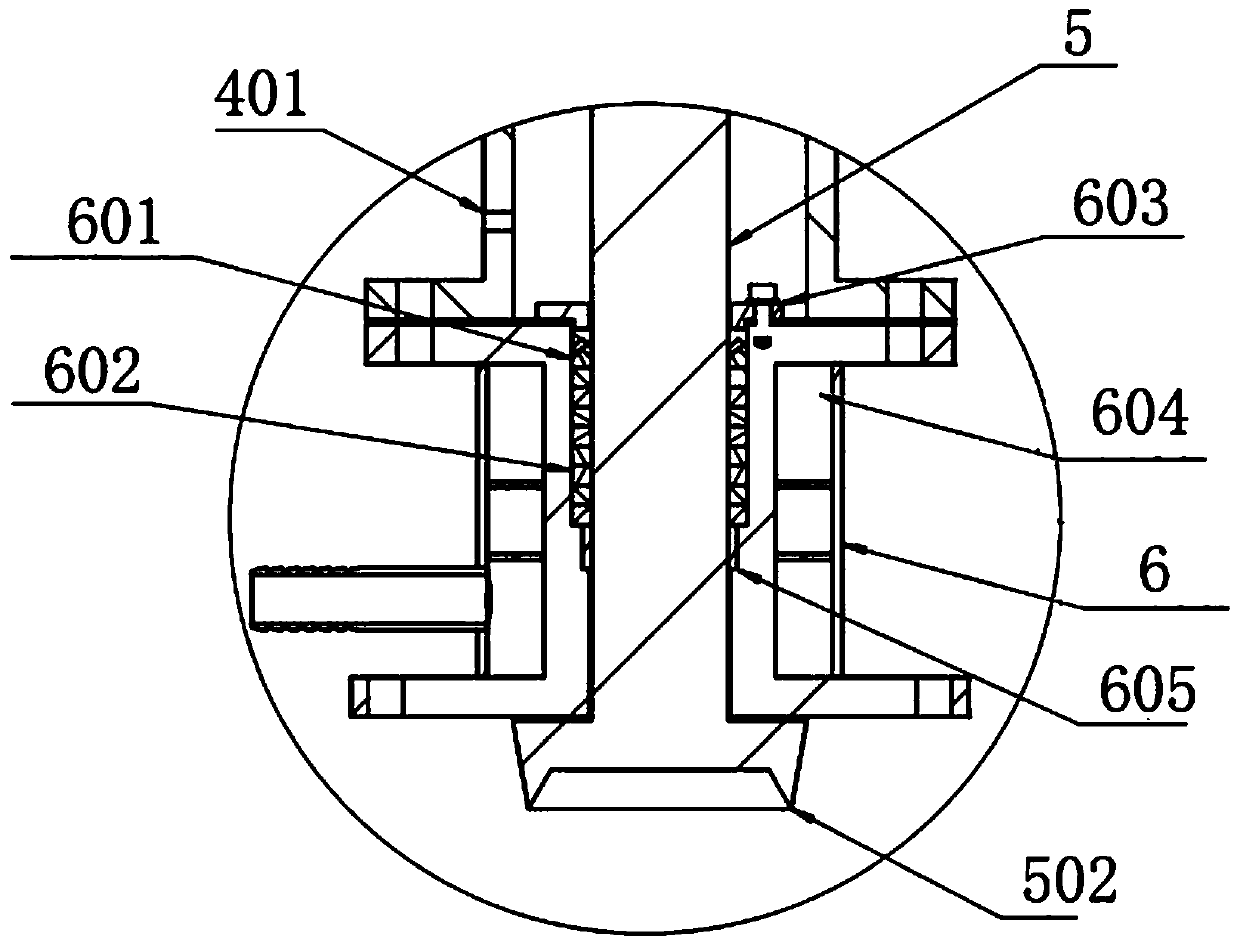

[0023] The technical solution of the present invention will be further described through specific implementation manners below in conjunction with the accompanying drawings.

[0024] As shown in the figure, a high-temperature dredging device for the distillation of sponge titanium is used in the distillation stage of magnesium reduction titanium tetrachloride method to produce sponge titanium. This stage is after the completion of the reduction stage, so it needs to be carried out under vacuum conditions. In order to isolate the air and prevent the oxygen in the air from oxidizing the reduced titanium, it is necessary to prevent air from entering the cold end reactor during the use of the device.

[0025] Based on this consideration, the present invention is mainly made up of these six parts of cylinder 1, piston rod 2, connecting support 3, cylinder support 4, dredging valve rod 5 and sealing valve seat 6; Wherein cylinder 1, connecting support 3, cylinder The support 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com