Capillary type efficient palladium-loaded zirconium based metal organic framework film microreactor, dynamic in-situ preparation method and application thereof

A technology of organic framework and micro-reactor, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of amino hydroxyl compounds, etc. It can solve the poor stability of ZIF-8 membrane and obtain membrane catalytic microreactor, which cannot realize the preparation of membrane catalysis layers and other issues to achieve the effect of solving poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

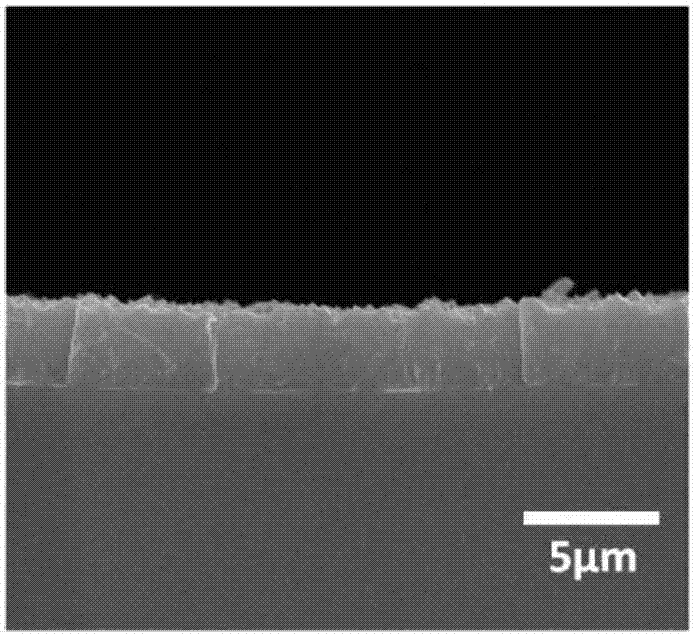

[0033] (1) UiO-66-NH on the capillary 2 Membrane synthesis

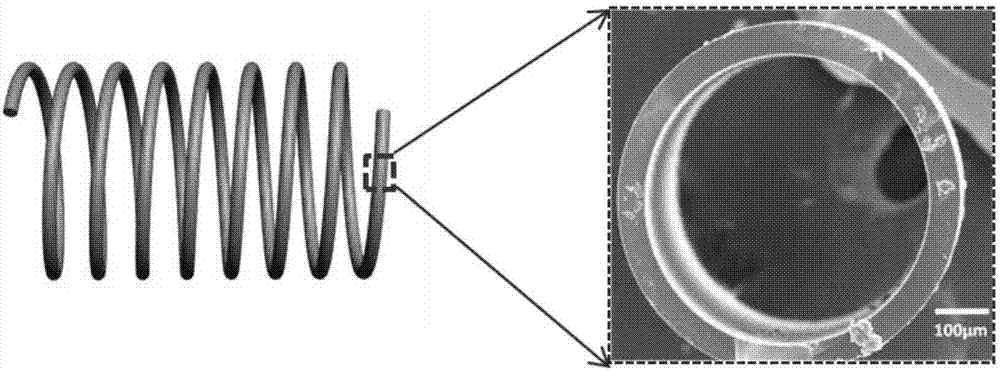

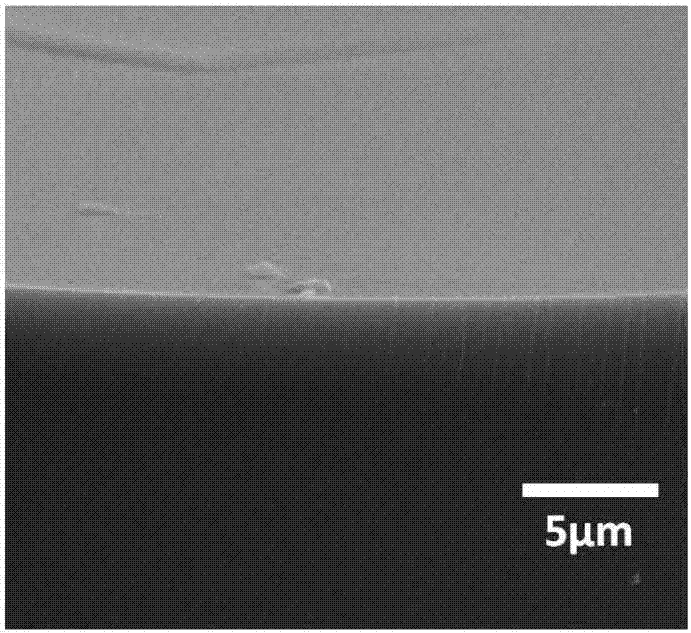

[0034] ①Select a capillary quartz tube with a length of 25cm and an inner diameter of 530μm as the microchannel. The cross-sectional topography of the capillary quartz tube is as follows Figure 1b ;

[0035] ②Prepare 20mL of 1mmol / L hydrochloric acid aqueous solution. At room temperature, with the help of a micro pump, continue to flow at a flow rate of 20μL / min for 30 minutes; then use deionized water to flow continuously at a flow rate of 20μL / min to wash away the acid until the capillary The pH at the outlet of the quartz tube is 7; prepare 20mL of 1mmol / L NaOH aqueous solution, and continue to flow at a flow rate of 20μL / min for 30min at 80℃ with the help of a micro pump; then use deionized water to flow continuously at a flow rate of 20μL / min , Wash away the lye until the pH at the outlet of the capillary quartz tube is 7, then air-dried at 100°C for later use;

[0036] ③ Measure 0.3 mL of 3-aminopropyltriethoxysilan...

Embodiment 2

[0046] (1) UiO-66-NH on capillary quartz tube 2 The synthesis of the membrane is the same as in Example 1;

[0047] (2)UiO-66-NH 2 Preparation of Pd Nanoparticles on Film

[0048] ①The preparation concentration is 0.02mmol / L H 2 PdCl 4 The HCl solution of 10mL, with the help of a micro pump, continues to flow at a flow rate of 20μL / min; the ambient temperature is 35°C. The flow time is 30 minutes, and then the residual palladium ions are dynamically treated and rinsed with deionized water at a flow rate of 20 μL / min at a temperature of 25°C;

[0049] ②Weigh 0.019g of NaBH 4 The solid is dissolved in 50mL deionized water and prepared into NaBH with a concentration of 10mmol / L 4 The aqueous solution, driven by a micro pump, flows continuously at a flow rate of 25 μL / min at room temperature for 4 hours, then rinses with deionized water and blast-dried at 80°C;

[0050] UiO-66-NH loaded with Pd nanoparticles 2 Membrane microreactor catalyzed NaBH 4 The application of reducing p-nitropheno...

Embodiment 3

[0052] (1) UiO-66-NH on capillary quartz tube 2 The synthesis of the membrane is the same as in Example 1;

[0053] (2)UiO-66-NH 2 Preparation of Pd Nanoparticles on Film

[0054] ①The preparation concentration is 2mmol / L H 2 PdCl 4 The HCl solution of 10mL, with the help of a micro pump, continues to flow at a flow rate of 20μL / min; the ambient temperature is 35°C. The flow time is 30 minutes, and then the residual palladium ions are dynamically treated and rinsed with deionized water at a flow rate of 20 μL / min at a temperature of 25°C;

[0055] ②Weigh 0.076g of NaBH 4 The solid is dissolved in 50mL deionized water to prepare NaBH with a concentration of 40mmol / L 4 The aqueous solution, driven by a micro pump, flows continuously at a flow rate of 25 μL / min at room temperature for 3 hours, then rinses with deionized water and blast-dried at 80°C;

[0056] UiO-66-NH loaded with Pd nanoparticles 2 Membrane microreactor catalyzed NaBH 4 The application of reducing p-nitrophenol is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com