Novel low-temperature anaerobic methane fermenting device

A biogas fermentation and low-temperature technology, applied in biochemical equipment and methods, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of heat preservation of the fermentation tank and equipment cost without consideration High, unreasonable structural design of the fermentation tank and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

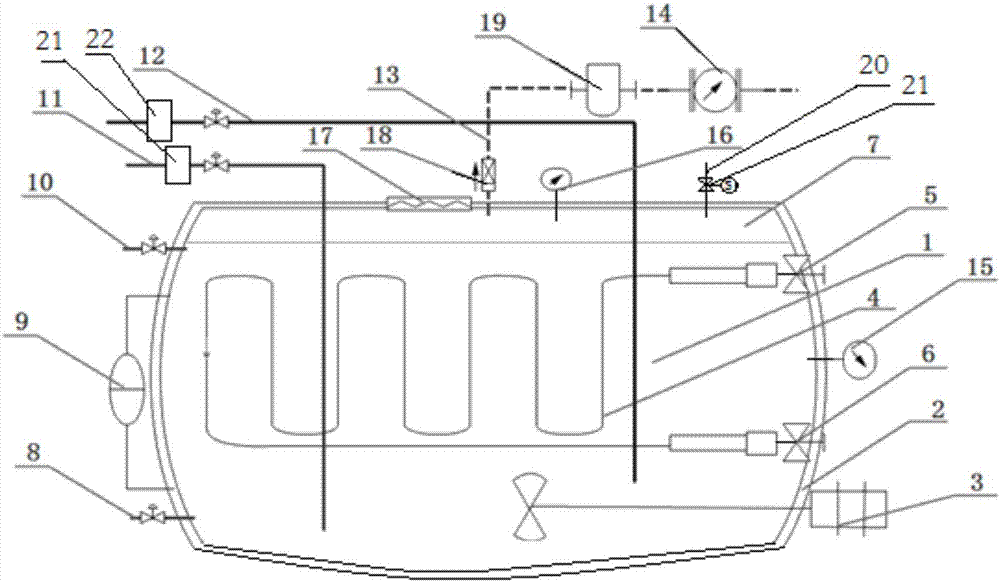

[0029] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0030] Such as figure 1As shown, a new type of low-temperature anaerobic biogas fermentation equipment includes an anaerobic biogas fermentation tank 1, and an anaerobic biogas fermentation tank 1 has a feed pipe 11 and a discharge pipe whose end extends into the anaerobic biogas fermentation tank 1. Pipe 12, the end of the feed pipe 11 located outside the anaerobic biogas fermentation tank 1 is connected to a feed pump 21, and the end of the discharge pipe 12 located outside the anaerobic biogas fermentation tank 1 is connected to a discharge pump 22, the anaerobic biogas The top of the fermentation tank body 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com