Method for separating and recovering chromium-zirconium-copper waste

A chromium-zirconium-copper and waste technology is applied in the field of separation and recovery of chromium-zirconium-copper waste, which can solve the problems of polluting environmental resources, low purity of copper salts, and failing to meet industrial standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

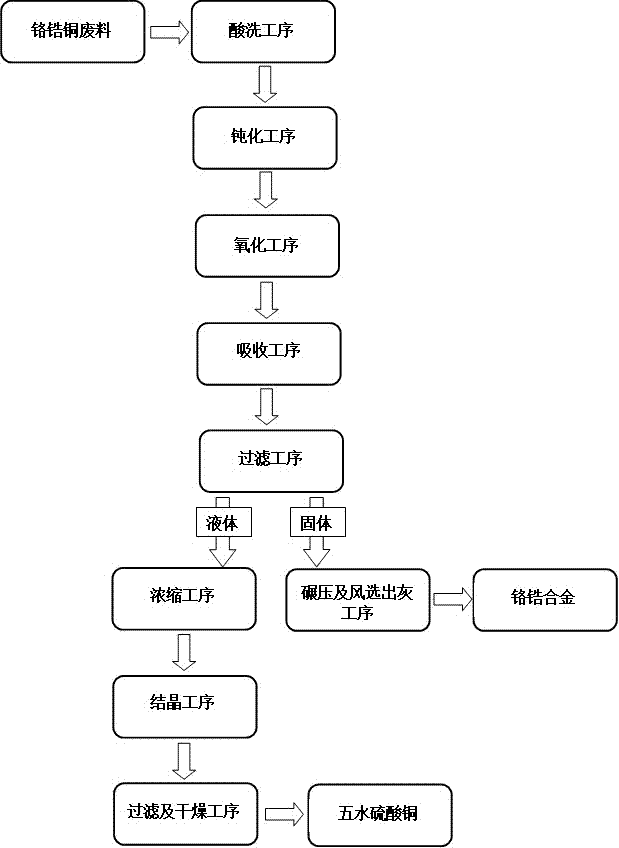

Image

Examples

Embodiment Construction

[0024] Pickling process:

[0025] Add 100g of chromium-zirconium-copper waste into a 500mL beaker, then add 100mL of dilute sulfuric acid aqueous solution with a volume fraction of 6%, pour out the dilute sulfuric acid (reusable) after reacting for 30min, and wash the chromium-zirconium-copper waste with water until pH=6.

[0026] Passivation process

[0027] Add 100 g of water and 1 mL of 34% nitric acid aqueous solution to the pickled waste to form a passivation film on the surface of the chromium-zirconium alloy. After 2 hours of reaction, the solid and liquid are separated, and the liquid can be recycled and reused.

[0028] Oxidation process

[0029] Add 350mL of 35% sulfuric acid aqueous solution and 80mL oxidant to the above solid, heat to 90°C and stir, the solution turns from colorless to blue.

[0030] Absorption process

[0031] The acid gas produced in the reaction process is absorbed with 200mL of 3% sodium carbonate solution (reusable), and then vented.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com